Mixed material casting apparatus for cooking

A technology for mixing materials and feeding devices, applied in applications, cooking utensils, household appliances, etc., can solve the problems of easy clogging of pipelines, poor sealing effect of containers, easy precipitation, etc., to achieve short material transportation distance and ensure cooking. The effect, the effect of the compact structure of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

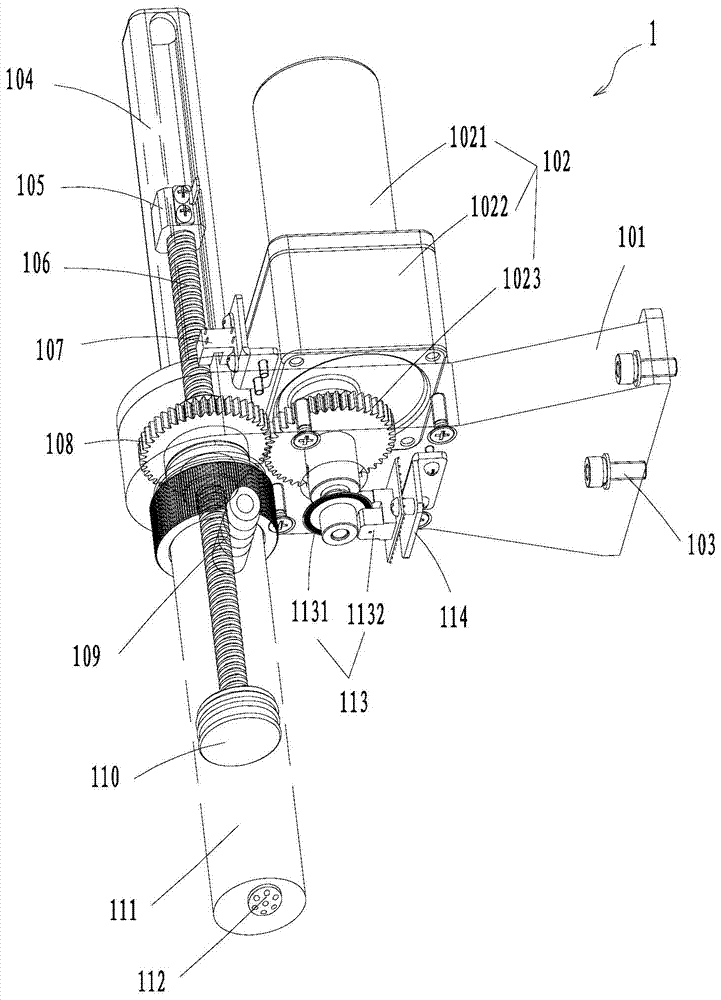

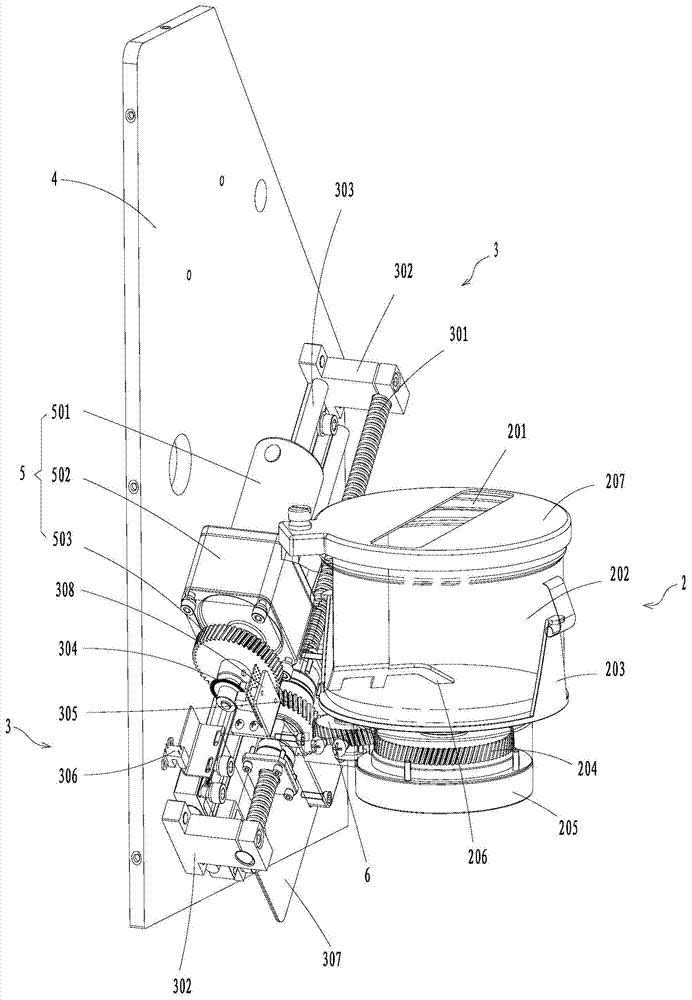

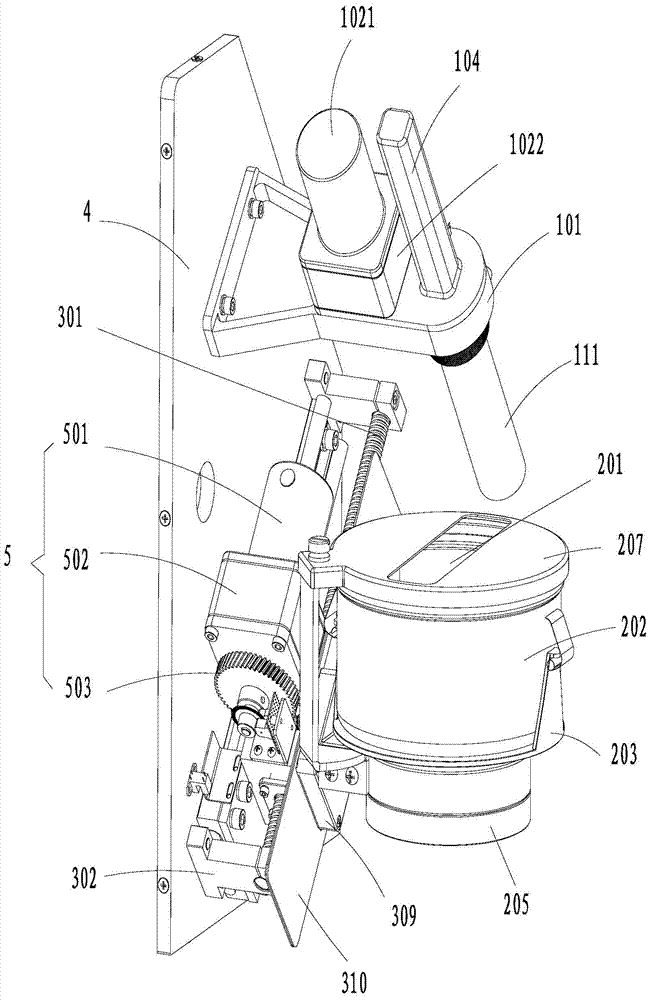

[0046] see Figure 2-Figure 4 The first structural mode in which the material suction and pushing mechanism 1 of the present invention cooperates with the material box 2 containing the mixture to transfer includes a mounting plate 4 fixed on the cooking equipment, and the mounting plate 4 is vertically arranged, wherein the outward The upper part of the side wall is provided with the above-mentioned mixed material suction and push mechanism 1, and the mixed material suction and push mechanism 1 is fixed on the installation plate 4 through fasteners 103, and the lower part of the installation plate 4 is provided with a transfer mechanism. The mechanism includes a second driving assembly 5 and a first sliding assembly 3 cooperating with the second driving assembly 5 , and the first sliding assembly 3 is connected with the cartridge 2 . When the mixed material is put in, the material box 2 can be moved horizontally or up and down at a certain angle with the horizontal plane as sh...

Embodiment 2

[0055] see Figure 5 The second structural mode in which the material suction and pushing mechanism 1 of the present invention cooperates with the material box 2 containing the mixed material to transfer includes a mounting plate 4' fixed on the cooking equipment. The mounting plate 4' is L-shaped, and its vertical Directly facing with a transfer mechanism, the transfer mechanism includes a second drive assembly 5 and a second slide assembly 7 that cooperates with the second drive assembly 5. The material suction push mechanism 1 is fixed on the second slide assembly 7, which can be controlled by the second drive assembly 5. The sliding assembly 7 is driven to move up and down or move up and down at a certain angle; the second drive assembly 5 cooperates with the material box 2, and drives the material box 2 to rotate around its own axis through an intermediate transmission component, so that The mixed material in the box body 202 of the magazine 2 is continuously stirred and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com