Novel high-performance hydrofluoric acid-resistance artificial functional composite plate and preparation method thereof

A technology of hydrofluoric acid resistance and composite plates, applied in the field of anti-corrosion materials, can solve problems such as easy leakage, hardness, flexural strength not meeting the requirements, pores, etc., achieve excellent mechanical properties and durability, and enhance market competition Power, the effect of reducing product costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1: The hydrofluoric acid-resistant novel high-performance man-made functional composite board is made of the following raw materials in proportions by mass:

[0027] Barite aggregate: 5 parts of 10 mesh to 20 mesh, 10 parts of 20 mesh to 40 mesh, 13 parts of 40 mesh to 70 mesh, 11 parts of 70 mesh to 180 mesh, 8 parts of 250 mesh, 12 parts of 325 mesh; 8 parts of resin part, 0.08 part of modifier, 0.04 part of accelerator, and 0.08 part of curing agent.

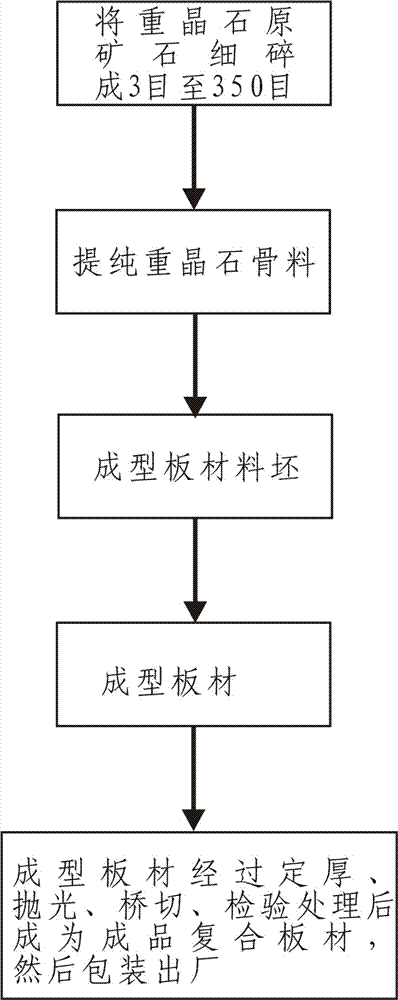

[0028] Such as figure 1 As shown, the preparation method is as follows: ① Finely crush the local barite raw ore into 3 mesh-350 mesh;

[0029] ②. Purification of barite aggregate: calcining the above-mentioned barite raw ore at 650°C-800°C for 2 hours, followed by water quenching, slag removal, purification, detachment and drying to obtain BaSo 4 Barite aggregate with a content of 85%-95%;

[0030] ③. Forming slab material billet, screen the above-mentioned barite aggregates of different meshes and add resi...

Embodiment 2

[0047] Example 2: The hydrofluoric acid-resistant novel high-performance man-made functional composite board is made of the following raw materials in proportions by mass:

[0048] Barite aggregate: 15 parts of 10 mesh to 20 mesh, 20 parts of 20 mesh to 40 mesh, 23 parts of 40 mesh to 70 mesh, 26 parts of 70 mesh to 180 mesh, 19 parts of 250 mesh, 21 parts of 325 mesh; 12 parts of resin parts, 0.42 parts of modifiers, 0.48 parts of accelerators, and 0.54 parts of curing agents.

[0049] Its preparation method is identical with embodiment 1.

[0050] The main indicators of the plate finished product produced according to the ratio of raw materials of this embodiment are as follows:

[0051] Compressive strength: ≥ 105 Mpa

[0052] Density: 4.4

[0053] Impermeability strength: Grade 1

[0054] Shrinkage rate 80~100℃: (0.03%)

[0055] Bond tensile strength: 9.5 Mpa

[0056] Hydrofluoric acid content 5~10% (resistance) Use temperature 125℃

[0057] Hydrofluoric acid conten...

Embodiment 3

[0059] Example 3: The hydrofluoric acid-resistant novel high-performance man-made functional composite board is made of the following raw materials in proportions by mass:

[0060] Barite aggregate: 10 parts from 10 mesh to 20 mesh, 15 parts from 20 mesh to 40 mesh, 18 parts from 40 mesh to 70 mesh, 19 parts from 70 mesh to 180 mesh, 13 parts from 250 mesh, 15 parts from 325 mesh; 10 parts of resin part, 0.2 part of modifier, 0.15 part of accelerator, and 0.15 part of curing agent.

[0061] Its preparation method is identical with embodiment 1.

[0062] The main indicators of the plate finished product produced according to the ratio of raw materials of this embodiment are as follows:

[0063] Compressive strength: ≥ 99.3 Mpa

[0064] Density: 4.2

[0065] Impermeability strength: Grade 1

[0066] Shrinkage rate 80~100℃: (0.02%)

[0067] Bond tensile strength: 9.0 Mpa

[0068] Hydrofluoric acid content 5~10% (resistance) Use temperature 125℃

[0069] Hydrofluoric acid c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com