Trackless mining method for gently inclined ore vein

A mining method and gently inclined technology, which is applied in the field of trackless mining of gently inclined veins, can solve the problems of large mining volume and high mining cost, and achieve the effects of large production capacity, reduced mining volume outside the vein, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

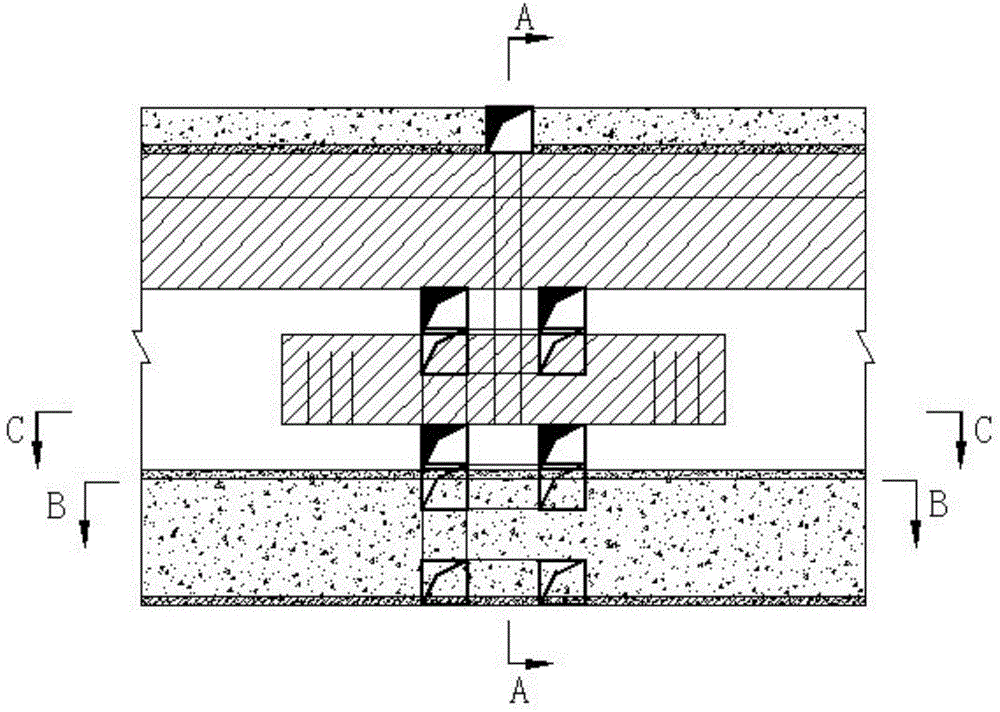

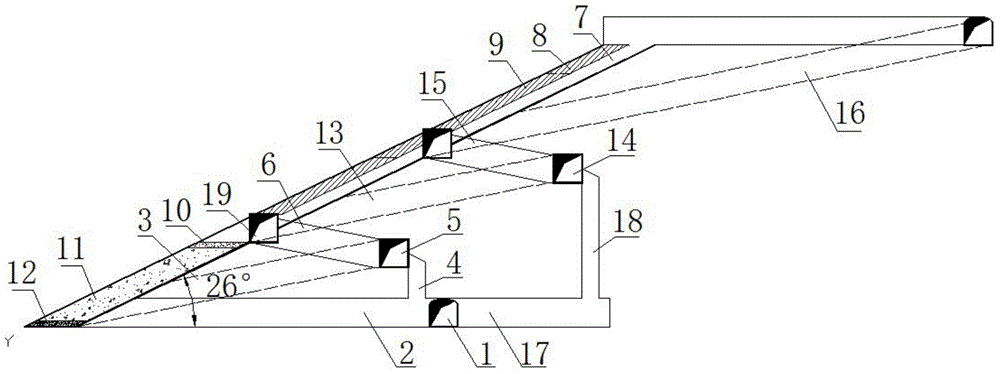

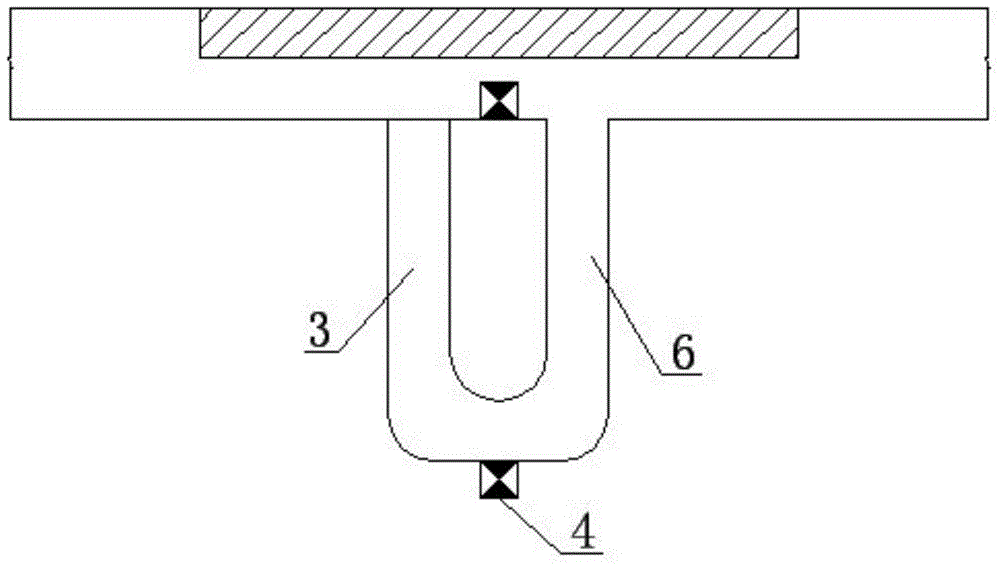

[0045] A method for trackless mining of gently inclined veins, mainly comprising the following method steps:

[0046] (1) Arrange the ore block along the vein direction, divide the ore vein into stages on the vertical height, the ore block is 60m long, and the stage height is 25m. One stage has three segments, the segment height is 7.5m, and the top pillar 8 is 2.5m thick; Fill the ventilation shaft 7 in the middle of the side of the footwall of the ore block parallel to the vein 9 and incline to open the vein. The length of the ventilation shaft 7 filled in the vein is oblique in stages, and the specification is 1.5×2m 2 ; From the stage transportation lane 1 corresponding to the middle position on the direction of the ore block, deviate from the direction of the ore vein 9, excavate the horizontal concentrated ore exit roadway 17 perpendicular to the direction of the ore vein 9, with a length of 13.49m; from the stage transportation lane 1 deviate from the direction of the or...

Embodiment 2

[0054] A method for trackless mining of gently inclined veins, mainly comprising the following method steps:

[0055] (1) Arrange the ore block along the vein direction, divide the ore vein into stages on the vertical height, the ore block is 40m long, and the stage height is 25m. One stage has three segments, the segment height is 7.5m, and the top pillar 8 is 2.5m thick; Fill the ventilation shaft 7 in the middle of the side of the footwall of the ore block parallel to the vein 9 and incline to open the vein. The length of the ventilation shaft 7 filled in the vein is oblique in stages, and the specification is 1.5×2m 2 ; From the stage transportation lane 1 corresponding to the middle position on the direction of the ore block, deviate from the direction of the ore vein 9, excavate the horizontal concentrated ore exit roadway 17 perpendicular to the direction of the ore vein 9, with a length of 13.49m; from the stage transportation lane 1 deviate from the direction of the or...

Embodiment 3

[0060] A method for trackless mining of gently inclined veins, mainly comprising the following method steps:

[0061] (1) Arrange the ore blocks along the vein direction, divide the ore veins into stages on the vertical height, the ore blocks are 100m long, and the stage height is 50m. One stage has three segments, the segment height is 7.5m, and the top pillar is 8m thick; The central position of the side of the footwall of the ore block is parallel to the ore vein 9 and is inclined to fill the ventilation shaft 7 in the open vein. The length of the ventilation shaft 7 filled in the vein is oblique in stages, and the specification is 1.5×2m 2 ; From the stage transportation lane 1 corresponding to the middle position on the direction of the ore block, deviate from the direction of the ore vein 9, excavate the horizontal concentrated ore exit roadway 17 perpendicular to the direction of the ore vein 9, with a length of 13.49m; from the stage transportation lane 1 deviate from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com