Three-dimensional composite current collector and preparation method thereof

A three-dimensional composite and current collector technology, applied in the field of three-dimensional current collectors and their preparation, can solve the problems such as the lack of improvement in the bonding performance of composite materials and metal lithium, unfavorable battery tab welding and large-scale production, and metal lithium falling off easily. It is beneficial to buffer the electrode polarization reaction, improve the electrochemical performance, and reduce the actual current density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The invention provides a method for preparing a three-dimensional composite current collector, comprising the following steps:

[0041] S1. Weigh a predetermined amount of carbon material, lithium-friendly metal oxide and lithium salt, mix and stir for 0.5-4 hours; add solvent and stir for 0.5-2 hours until completely dissolved; then add a predetermined amount of binder, stir for 4-10 hours, and prepare Obtain lithium battery negative electrode lithium-friendly material slurry;

[0042] S2. Select a copper foil with a thickness of 6-20 μm as the base layer, apply the slurry on the copper foil at a coating speed of 10-30 m / min, and then dry it in a blast drying oven at 70-80°C for 4- 8h, and then dried in a vacuum oven at 110-130°C for 8-12h to prepare a three-dimensional composite current collector.

[0043] Further, the solvent is one of water and N-methylpyrrolidone.

[0044] Further, in step S1, the mass ratio of the carbon material, the lithium-philic metal oxide,...

Embodiment 1

[0051] Preparation method of three-dimensional composite current collector:

[0052] S1. Weigh 30g of carbon nanotubes and 55g of copper oxide particles in a stirring tank and stir for 2 hours; then add 10g of lithium carbonate into the stirring tank and stir for 2 hours, then add an appropriate amount of N-methylpyrrolidone, and stir for 2 hours until completely dissolved; then Add 5 g of polyvinylidene fluoride into the stirring tank and stir for 10 hours to prepare a lithium battery negative electrode lithium-friendly material slurry;

[0053] S2. Select a copper foil with a thickness of 8 μm and no impurities on the surface as the base layer, apply the slurry on the copper foil, apply it with a coating machine at a coating speed of 10m / min, and then place it on the air to dry Baking in an oven at 75°C for 4 hours, and finally baking in a vacuum oven at 120°C for 12 hours to prepare a three-dimensional composite current collector.

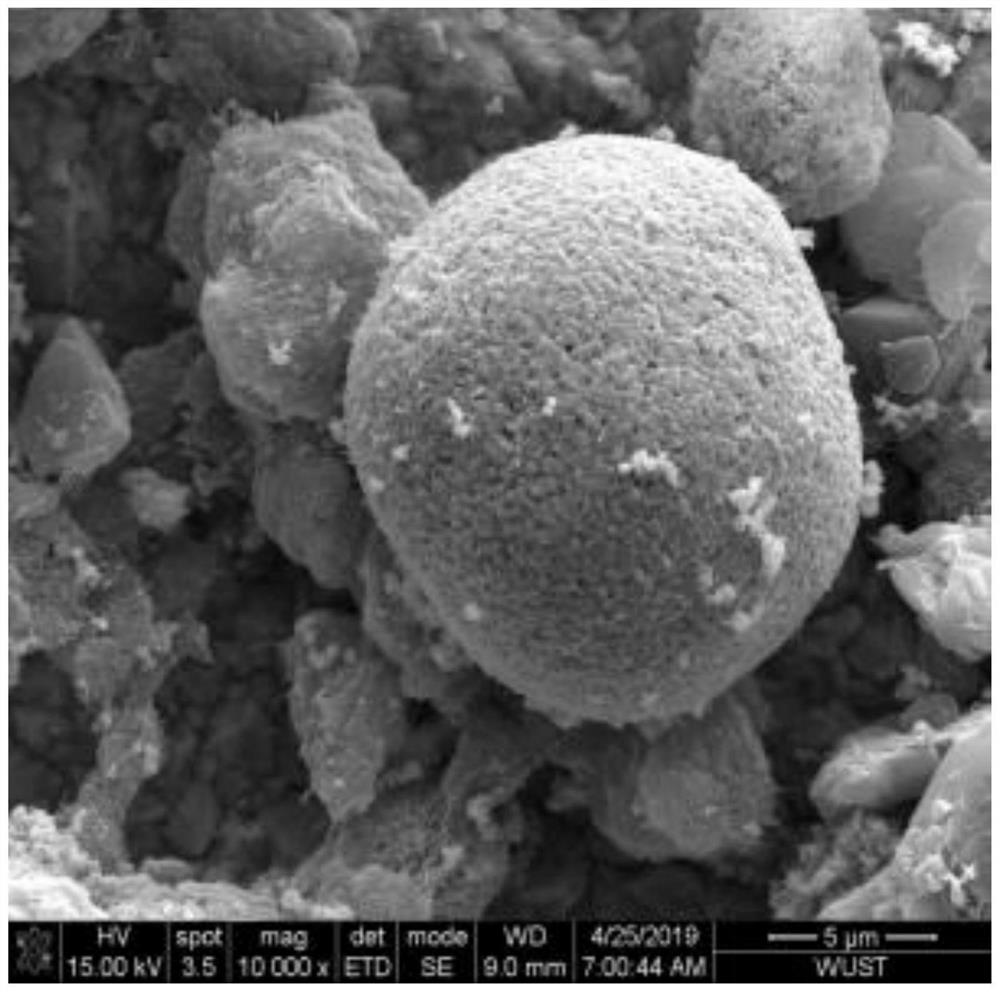

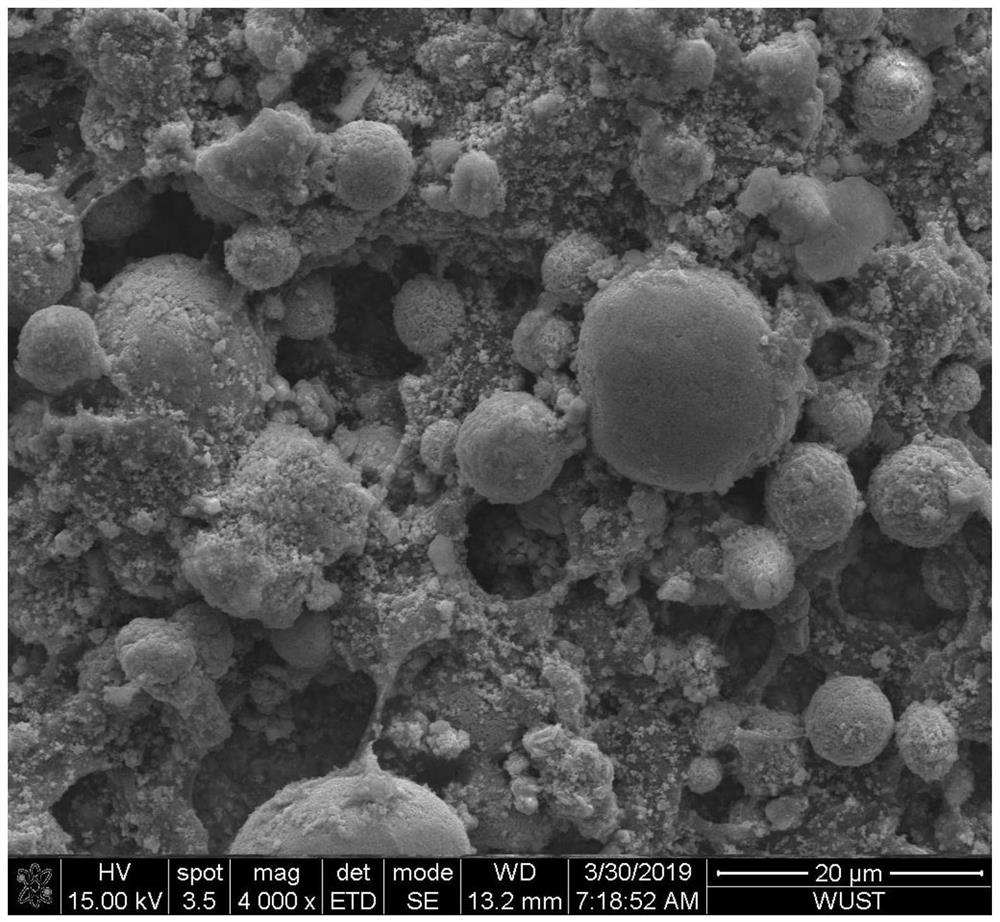

[0054] see Figure 1-5 The three-dimens...

Embodiment 2

[0076] Preparation method of three-dimensional composite current collector:

[0077] S1. Weigh 30g of carbon nanotubes and 55g of zinc oxide particles in a stirring tank and stir for 2 hours; then add 10g of lithium carbonate into the stirring tank and stir for 2 hours, then add an appropriate amount of N-methylpyrrolidone, and stir for 2 hours until completely dissolved; then Add 5g of polyacrylonitrile LA133 into the stirring tank and stir for 10h to prepare lithium battery negative electrode lithium-friendly material slurry;

[0078] S2. Select a copper foil with a thickness of 8 μm and no impurities on the surface as the base layer, apply the slurry on the copper foil, apply it with a coating machine at a coating speed of 10m / min, and then place it on the air to dry Baking in an oven at 75°C for 4 hours, and finally baking in a vacuum oven at 120°C for 12 hours to prepare a three-dimensional composite current collector.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com