Air purifier for removing harmful gas and dust in long tunnel

A harmful gas and dust technology, which is applied in the field of traffic engineering, traffic tunnel construction, and mine shaft construction without gas gushing. It can solve the problems of long ventilation time, large pressure loss, and high equipment damage rate, so as to shorten the ventilation time, The effect of improving air quality and speeding up construction progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

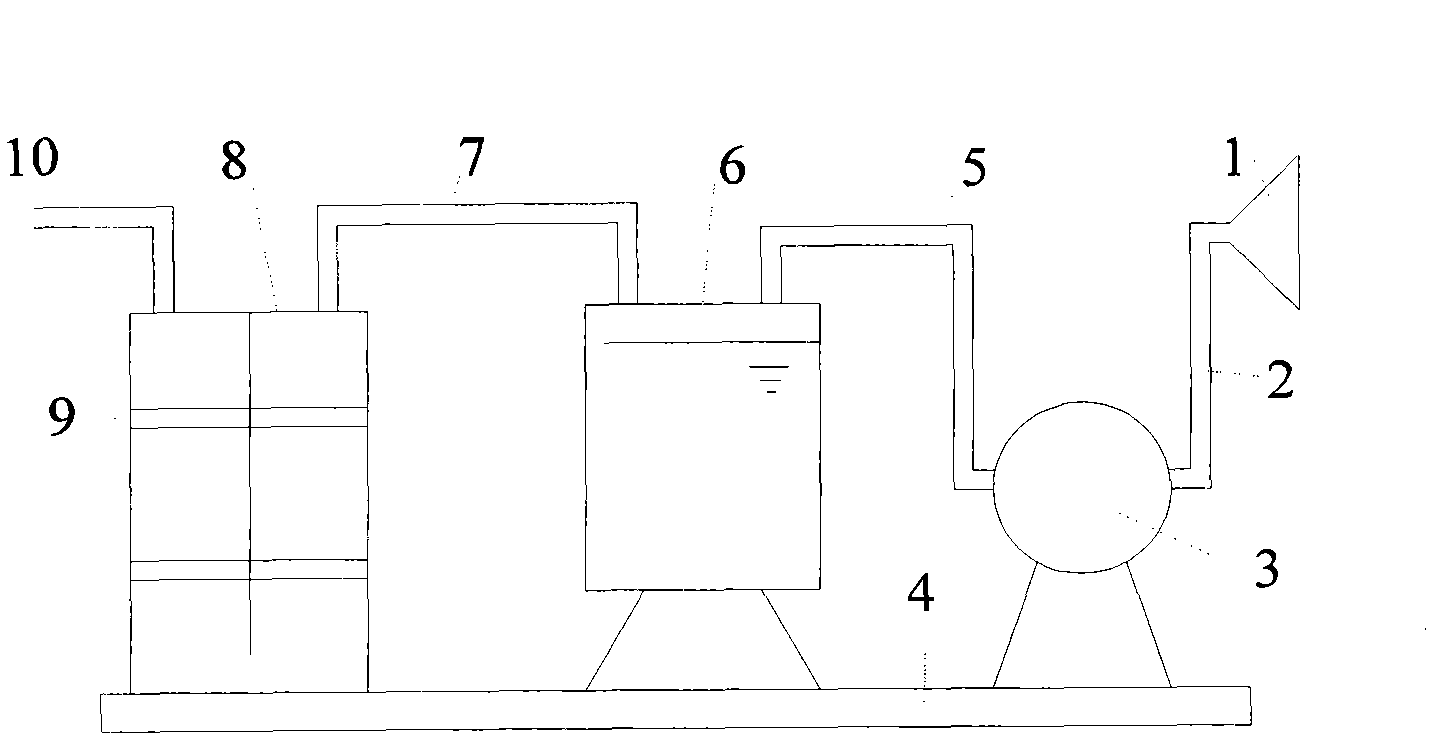

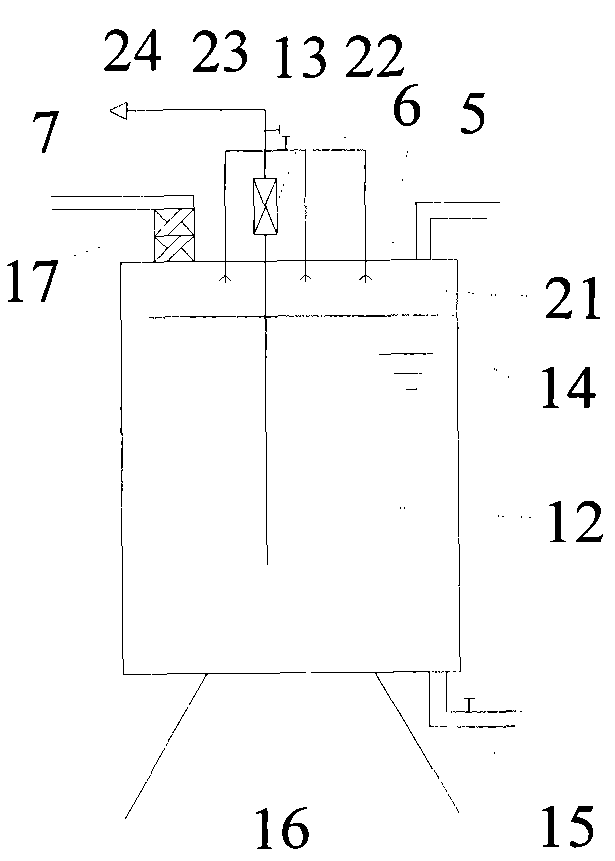

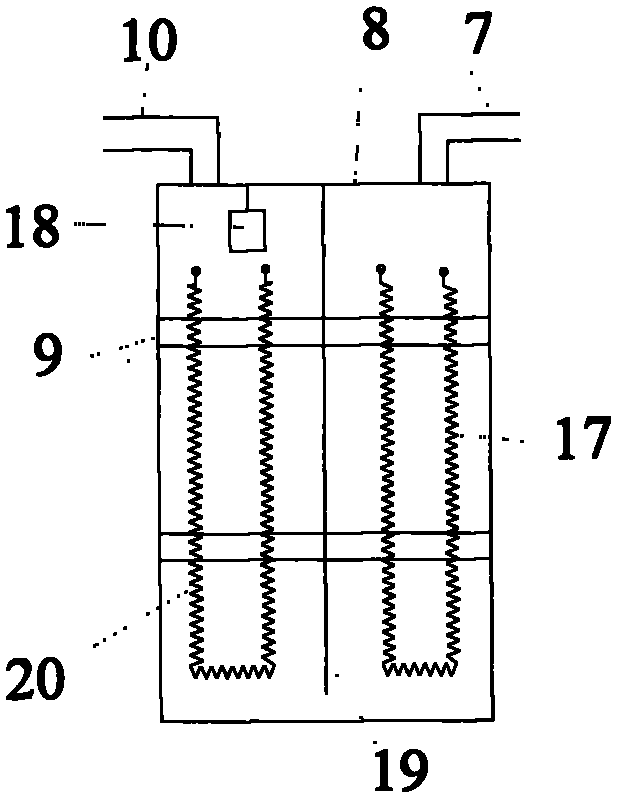

[0032] The harmful gases CO and CO in the tunnel are periodically removed by the mobile fan. 2 , NO, NO 2 , sulfide and dust are sent to the degradation tank by the fan. Adopt centrifugal fan, pressure 4kPa, air volume 2300m 3 / h, inhaling harmful gases CO, CO in the tunnel 2 , NO, NO 2 , sulfide, dust, sent to the degradation tank, through the reaction or cleaning with the alkaline compound in the degradation tank, preferably the alkaline compound sodium carbonate, CO, a small amount of NO, water vapor that is difficult to react with the alkaline compound, filtered through the porous fiber separation membrane after water vapor. The CO and a small amount of NO filtered from the porous fiber separation membrane enter the low-temperature pressure swing adsorption tower with a temperature of 10 to 30 °C for adsorption. The electrothermal heating belt heats the adsorption tower to 80-135°C, preferably 100°C, to desorb CO and NO.

Embodiment 2

[0034] The harmful gases CO and CO in the tunnel are periodically removed by the mobile fan. 2 , NO, NO 2 , sulfide and dust are sent to the degradation tank by the fan. Adopt centrifugal fan, pressure 3kPa, air volume 2700m 3 / h, inhaling harmful gases CO, CO in the tunnel 2 , NO, NO 2 , sulfide, dust, sent to the degradation tank, through the reaction or cleaning with the alkaline compound in the degradation tank, preferably the alkaline compound sodium carbonate, CO, a small amount of NO, water vapor that is difficult to react with the alkaline compound, filtered through the porous fiber separation membrane after water vapor. The CO and a small amount of NO filtered from the porous fiber separation membrane, at a pressure of 3 kPa, enter the low temperature pressure swing adsorption tower with a temperature of 10 to 30 ° C for adsorption, CO and a small amount of NO are adsorbed in the adsorption tower, and then the pressure swing adsorption tower is adsorbed and transp...

Embodiment 3

[0036]The harmful gases CO and CO in the tunnel are periodically removed by the mobile fan. 2 , NO, NO 2 , sulfide and dust are sent to the degradation tank by the fan. Adopt centrifugal fan, pressure 2kPa, 2900m 3 / h, inhaling harmful gases CO, CO in the tunnel 2 , NO, NO 2 , sulfide, dust, sent to the degradation tank, through the reaction or cleaning with the alkaline compound in the degradation tank, preferably the alkaline compound sodium carbonate, CO, a small amount of NO, water vapor that is difficult to react with the alkaline compound, filtered through the porous fiber separation membrane after water vapor. CO and a small amount of NO filtered from the porous fiber separation membrane, at a pressure of 2kPa, enter a low temperature pressure swing adsorption tower with a temperature of 10 to 30 °C for adsorption, CO and a small amount of NO are adsorbed in the adsorption tower, and then the pressure swing adsorption tower is adsorbed and transported out In the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com