Ventilation method for auxiliary double-hole construction in inclined shaft

A ventilation method and ventilation method technology, which is applied to the ventilation of mines/tunnels, earthwork drilling, mining equipment, etc., to achieve the effects of saving air ducts, good effect, and high ventilation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

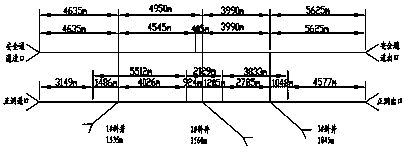

[0031] This example takes the Angren-Pop railway in Uzbekistan as an example of the 1# inclined shaft of the Kurami Tunnel. The design speed of the Angren-Pop railway is 40km / h. The length of the main tunnel is 19.3km. At the same time, a safety tunnel (19.3km in length) parallel to the main tunnel is built. The distance between the main tunnel and the center of the safety tunnel is 29m. The main tunnel and the safety tunnel are connected by connecting channels, and the distance between the connecting channels is 300m. The tunnel must be completed on September 1, 2016. In order to meet the requirements of the construction period, three inclined shafts will be set up to assist the construction. The tunnel must be completed on September 1, 2016. In order to meet the requirements of the construction period, three inclined shafts will be set up to assist the construction. The amount of construction tasks for the positive hole of each auxiliary inclined shaft is shown in Table 1-1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com