Method for transporting road rail iron in mine and road rail iron transport vehicle

A technology of transport vehicles and car bodies, which is applied in the direction of transporting passenger cars, transportation and packaging, railway car body parts, etc., and can solve problems such as low work efficiency and high labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

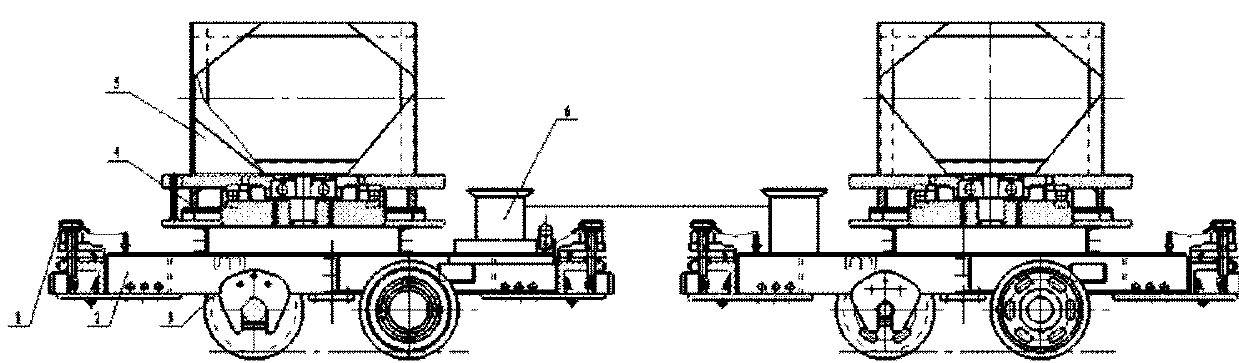

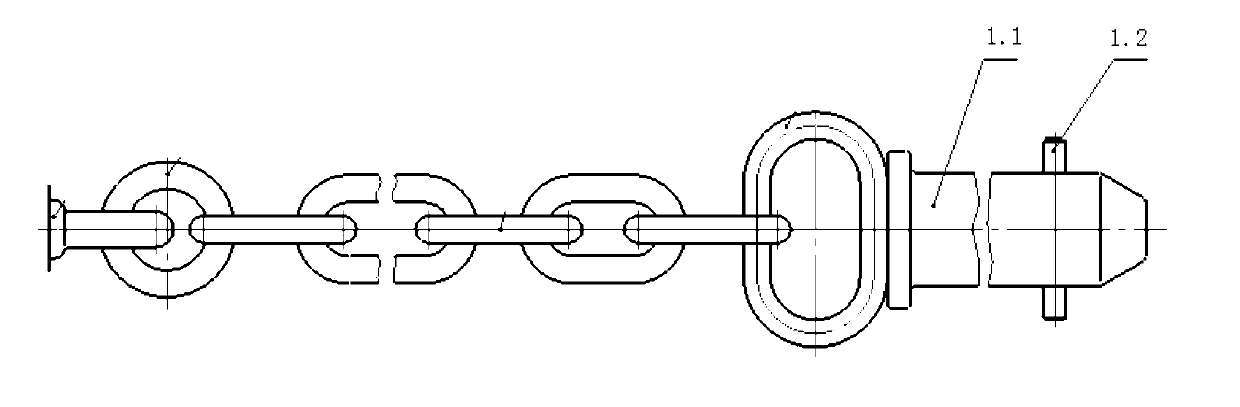

[0024] Such as figure 1 , 2 , shown in 3, 4, and 5: a kind of road railway transport vehicle, comprising: car A, car B, is made up of the car A that connects car B softly by steel wire rope in front, and described steel rope passes through car A, car B of two cars The ratchet tensioning device set on the frame 2 of the vehicle adjusts the distance between the two vehicles, and the distance is adjusted between 6m and 10m; A car body 5 for transporting railroad is provided; where the two ends of the vehicle frame 2 are respectively provided with latch anti-drop chains 1 , and the outer ends of the latch anti-drop chains 1 are provided with buffers.

[0025] The car body 5 of the car A is open at one end, and is provided with a stopper end.

[0026] The car body 5 of the car B is open at both ends.

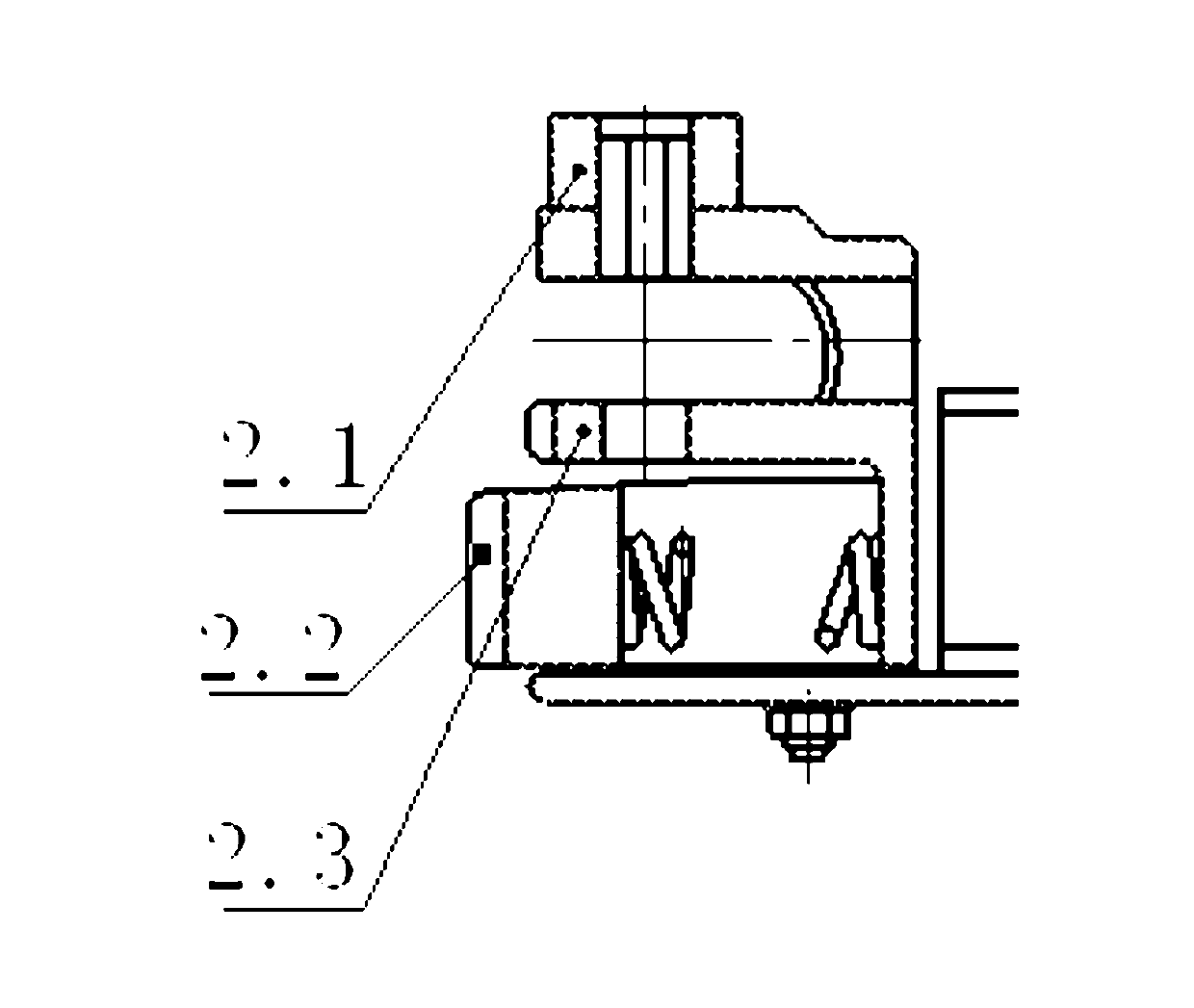

[0027] The ratchet tensioning device 6 is composed of a ratchet reel 1 , a frame part 2 and a handle 3 .

[0028] The bolt anti-drop chain 1 has a fixed structure to prevent the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com