Pressure die-casting production line for iron pans

A technology of production line and cast iron pot, which is applied in the field of die-cast iron pot production line, can solve the problems of simple structure and low manufacturing efficiency of iron pot, and achieve the effect of high-efficiency manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

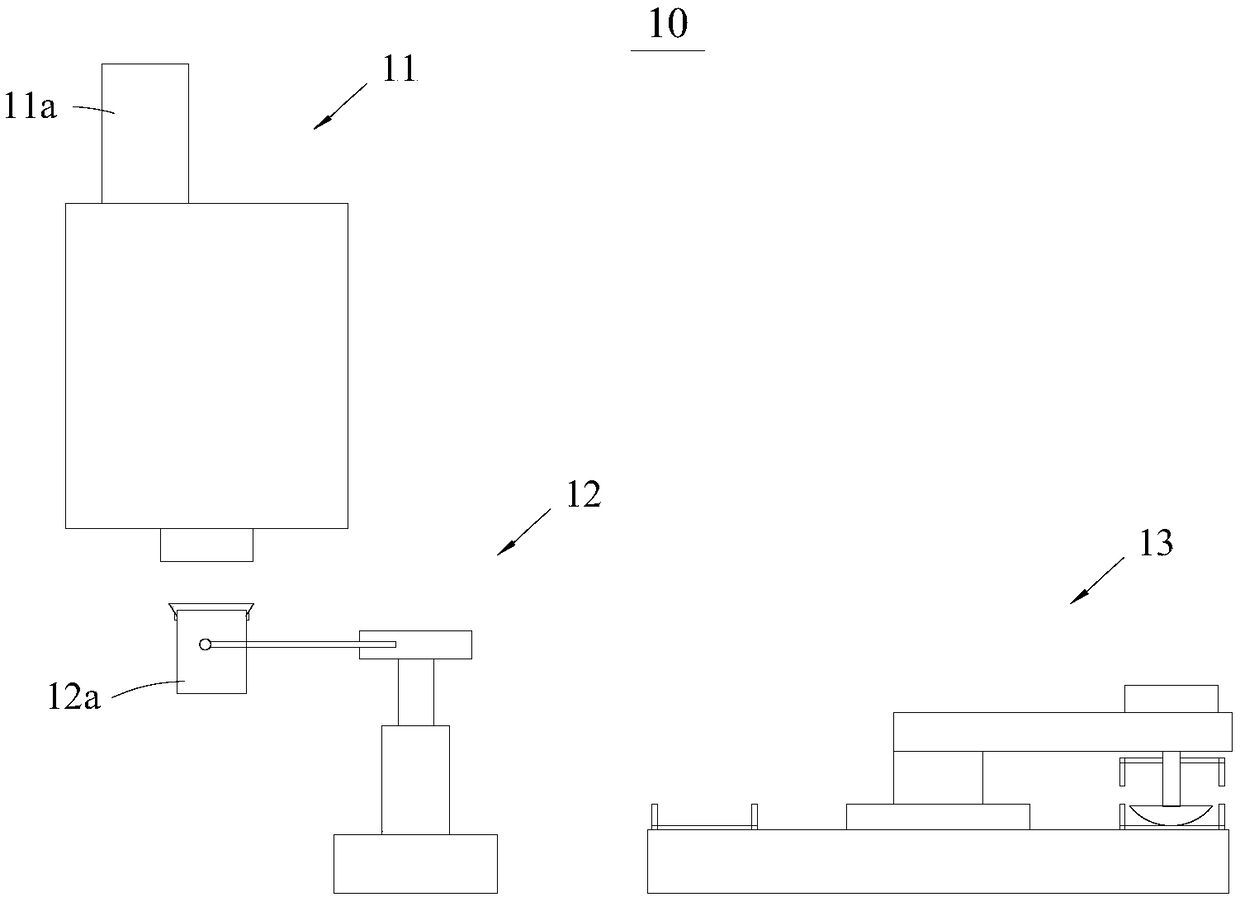

[0057] This embodiment provides a die-casting iron pan production line 10, which can efficiently manufacture iron pans.

[0058] Please refer to figure 1 , figure 1 The specific structure of the die-cast iron pan production line 10 in this embodiment is shown.

[0059] The die-cast iron pan production line 10 includes a molten iron smelting device 11 , a molten iron transfer device 12 and a die-casting device 13 .

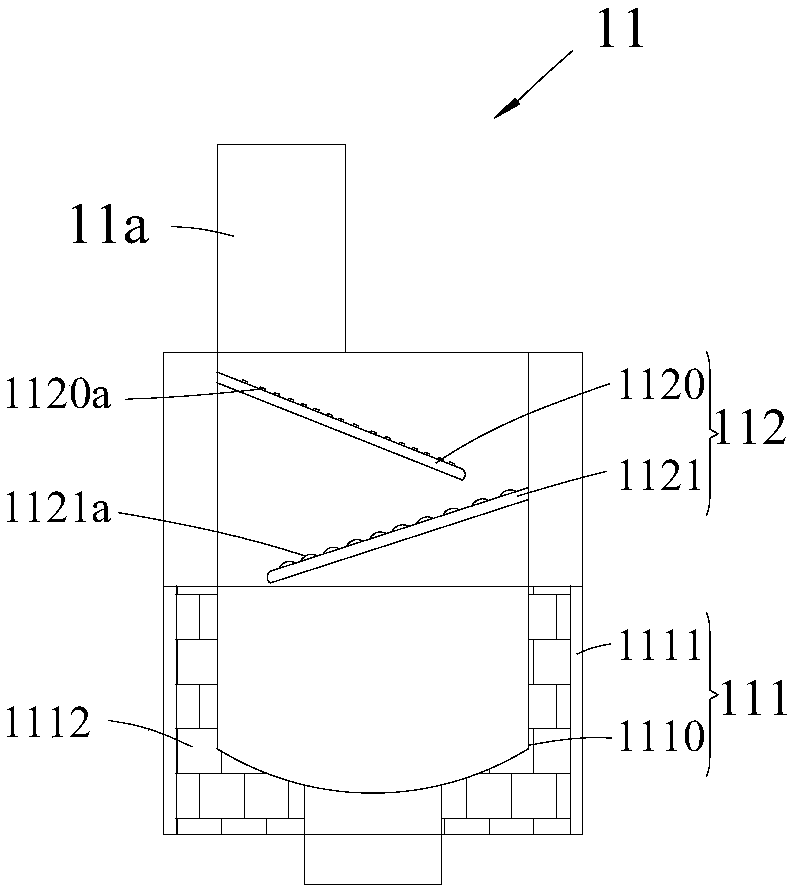

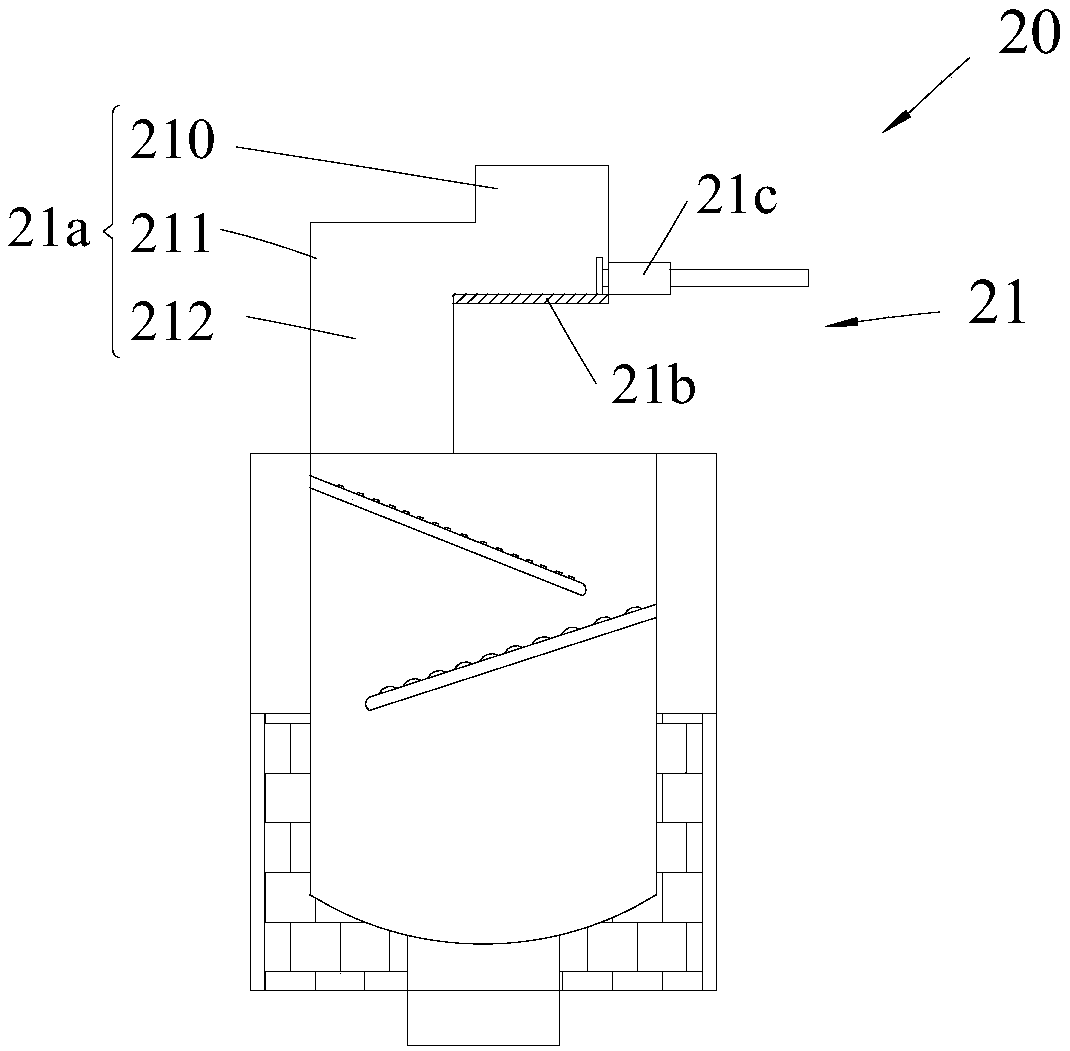

[0060] The molten iron smelting device 11 has a smelting space for smelting pig iron inside, and the molten iron smelting device 11 has a feeding portion 11 a communicating with the smelting space and a molten iron outlet.

[0061] The molten iron transfer device 12 has a receiving container 12a for accepting the molten iron delivered from the molten iron outlet.

[0062] The die-casting device 13 includes a turntable 13a, a plurality of die-casting lower molds 13b arranged on the turntable 13a and an upper die-casting mold 13c arranged on the turntable 13a, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com