Blowing-type furnace protection charge for blast furnace and using method of blowing-type furnace protection charge

A technology for protecting furnace materials and blast furnaces, which is applied to blast furnaces, blast furnace details, blast furnace parts, etc., can solve the problems of low utilization rate of molten iron [Ti], large amount of titanium-containing materials, and inability to increase molten iron, etc., to shorten furnace protection time, The effect of improving the utilization rate and increasing the amount of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

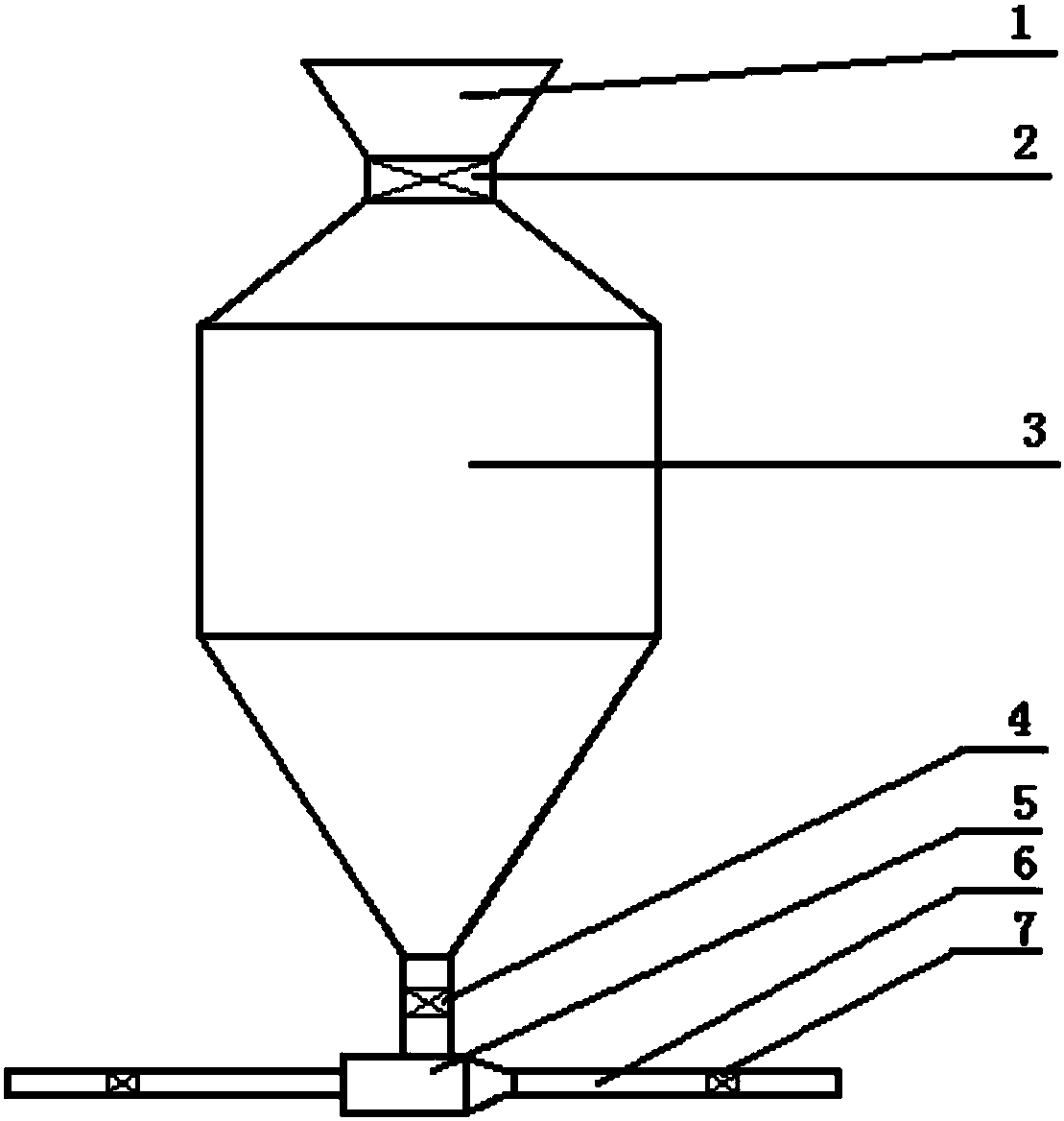

Image

Examples

Embodiment 1

[0022] Blast furnace injection protection material, chemical composition and weight percentage content: 25% of ferrosilicon nitride; 75% of titanium concentrate powder.

[0023] Among them: N=38% in ferrosilicon nitride; Fe=12%; Si=49%; TiO in titanium concentrate powder 2 = 48%. The maximum particle size of each solid raw material is ≤1.5mm.

[0024] at a certain 1200M 3 For the blast furnace, use the furnace protection material injection tank to spray the above-mentioned blast furnace injection furnace protection material into the furnace from the tuyere above the repaired part of the hearth, with a total of 85 tons, and a good repair effect is obtained.

Embodiment 2

[0026] Blast furnace injection protection material, chemical composition and weight percentage content: manganese silicon nitride 15%; ferrosilicon nitride 15%; titanium concentrate powder 70%.

[0027] Among them: N=28% in manganese silicon nitride; Mn=14%; Si=46%; N=35% in ferrosilicon nitride; Fe=15%; Si=48%; TiO in titanium concentrate powder 2 = 52%. The maximum particle size of each solid raw material is ≤1.5mm.

[0028] In a certain 2600M 3 For the blast furnace, use the furnace protection material injection tank to spray the above-mentioned blast furnace injection furnace protection material into the furnace from the tuyere above the hearth repair part, with a total of 95 tons, and a good repair effect is obtained.

Embodiment 3

[0030] Blast furnace injection protection material, the chemical composition and weight percentage content are: manganese nitride silicon 30%; titanium concentrate powder 70%.

[0031] Among them: N=30% in manganese nitride silicon; Mn=15%; Si=45%; TiO in titanium concentrate powder 2 = 49%. The maximum particle size of each solid raw material is ≤2.0mm.

[0032] In a 3200M3 blast furnace, the above-mentioned blast furnace injection furnace protection material was sprayed into the furnace from the tuyere above the hearth repair part by using the furnace protection material injection tank, with a total of 110 tons, and a good repair effect was obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com