Enamel steel and steel substrate and preparation method thereof

A technology of enamel steel and steel substrate, applied in the field of enamel steel and its steel substrate and preparation, which can solve the problems such as easy occurrence of phosphorus explosion in the enamel layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

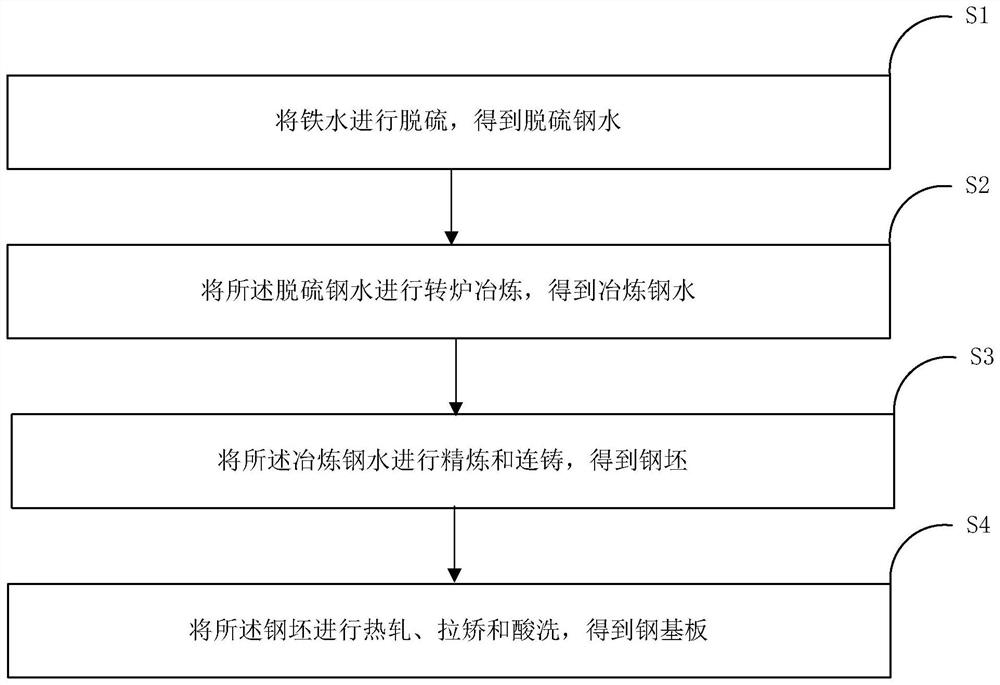

[0051] According to another typical embodiment of the present invention, there is provided a method for preparing a steel substrate of enamelled steel as described above, the method comprising:

[0052] S1. Desulfurizing molten iron to obtain desulfurized molten steel;

[0053] S2. performing converter smelting on the desulfurized molten steel to obtain smelted molten steel;

[0054] S3. Refining and continuous casting the molten steel to obtain a billet;

[0055] In some embodiments, the key points of steelmaking process control: steelmaking process process route KR—BOF—RH—CC;

[0056] KR: ultra-low S removal, slag removal bright surface ≥ 95%, post-slag removal ≥ 2 times, control residual S at 0.0010-0.0020%;

[0057] The reason for controlling the slagging bright surface ≥ 95% is to ensure sufficient removal of S-containing slag and iron, and the adverse effect of this value being too small is to cause sulfur return in the subsequent converter process.

[0058] The reaso...

Embodiment 1

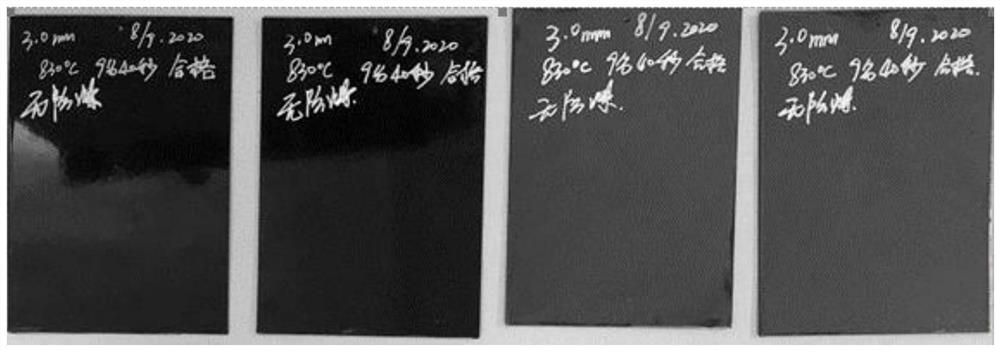

[0076] An enamelled steel, the thickness of which is 3.0mm;

[0077] Composition of enamelled steel: C: 0.0314%; Si: 0.0064%; Mn: 0.232%; P: 0.0073%; S: 0.0054%;

[0078] Hot rolling process control of enamel steel: heating furnace temperature 1200°C, RT2: 1140°C, finish rolling entrance temperature: 1070°C, finish rolling exit temperature: 870°C, coiling temperature 620°C.

Embodiment 2

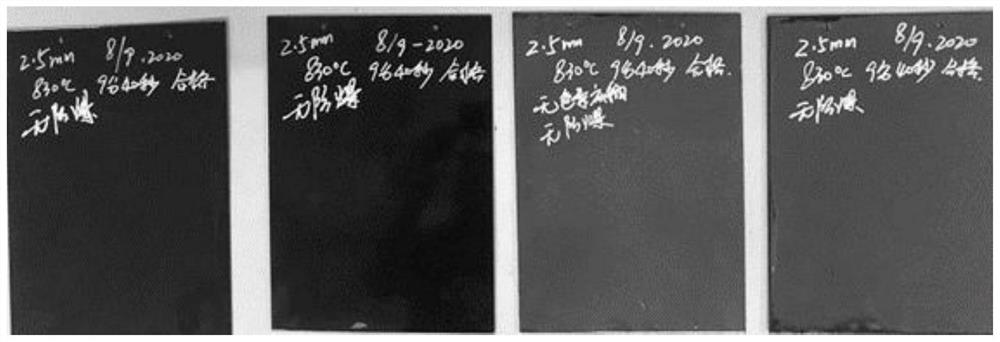

[0080] A kind of enamelled steel, the thickness of enamelled steel is 2.5mm;

[0081] Composition of enamelled steel: C: 0.0318%; Si: 0.0071%; Mn: 0.245%; P: 0.0078%; S: 0.0064%;

[0082] Hot rolling process control of enamel steel: heating furnace temperature 1200°C, RT2: 1150°C, finish rolling entrance temperature: 1050°C, finish rolling exit temperature: 880°C, coiling temperature 630°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com