Titaniferous carbon steel and production method thereof

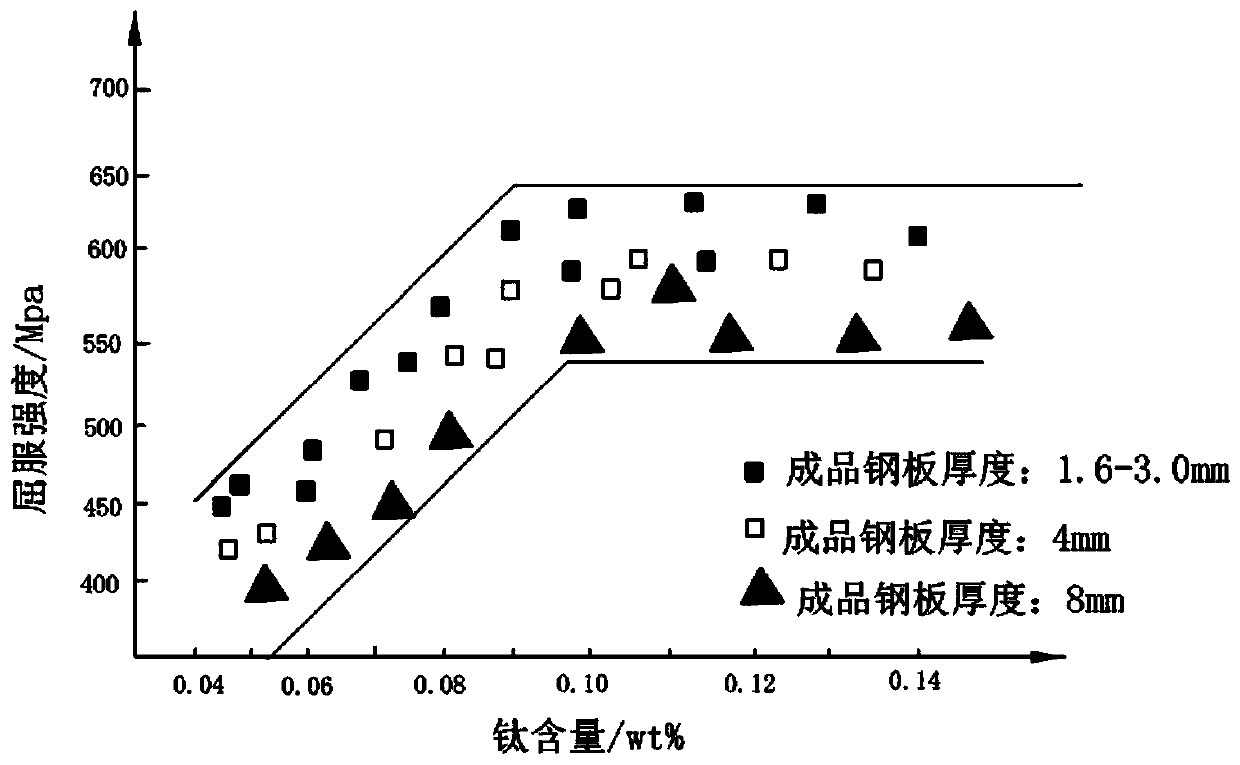

A technology of titanium carbon and molten steel, applied in the field of steel rolling, can solve the problems of fluctuating and inaccurate strength of finished steel products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

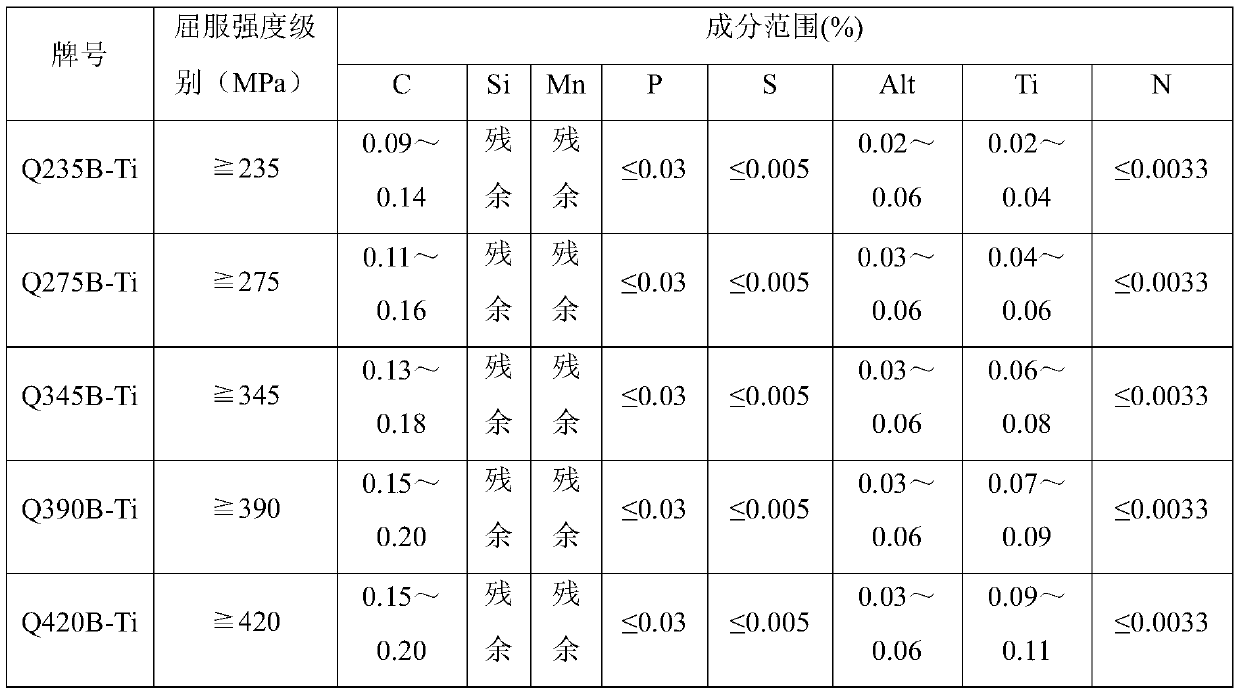

[0078] Titanium-containing carbon structural steel with the brand name Q235B, a hot-rolled steel strip and a preparation method thereof. This type of steel only uses carbon and titanium to strengthen the steel, and does not add silicon-based and manganese-based alloys.

[0079] The preparation method of the titanium-containing carbon hot-rolled steel strip of brand Q235B specifically comprises the following steps:

[0080] (1) Hot metal pretreatment: carry out deep desulfurization operation, control S in hot metal ≤ 0.01%, and remove desulfurization slag.

[0081] (2) The molten iron after pretreatment enters the converter. In the middle and later stages of smelting, the bottom blowing gas is switched from nitrogen to argon, and the P in the tapping molten steel is controlled to be 0.016%, and the C is 0.12%. The content is less than 20ppm.

[0082] Control the temperature of the tapping molten steel to prevent the peroxidation of the molten steel; maintain the shape of the ...

Embodiment 2

[0101] The grade is Q275B titanium-containing hot-rolled steel strip (Q275B-Ti) and its production method. This steel type only uses carbon and titanium to strengthen the steel, and does not add silicon-based and manganese-based alloys.

[0102] Concrete preparation method comprises the following steps:

[0103] (1) Deep desulfurization operation is carried out in the molten iron pretreatment link, and the S in the molten iron is controlled to be less than or equal to 0.01%, and the desulfurization slag is completely removed.

[0104] (2) The molten iron after pretreatment enters the converter. In the middle and late stages of converter smelting, the bottom blowing gas is switched from nitrogen to argon, and the P in the tapping molten steel is controlled to be 0.015%, and the C in the tapping molten steel is 0.10%, so as to prevent overoxidation of the molten steel. The temperature of the tapping molten steel is 1640°C, maintain the shape of the tapping hole, make the tapping...

Embodiment 3

[0120] A titanium-containing carbon structural steel (Q345B-Ti) hot-rolled steel strip with the brand name Q345B and a production method thereof. This type of steel only uses carbon and titanium to strengthen the steel, and does not add silicon-based and manganese-based alloys.

[0121] Concrete preparation method comprises the following steps:

[0122] (1) Deep desulfurization operation is carried out in the molten iron pretreatment link, and the S in the molten iron is controlled to be less than or equal to 0.01, and the desulfurization slag is pulled out to remove the desulfurization slag.

[0123] (2) The molten iron after pretreatment enters the converter. In the middle and late stages of converter smelting, the bottom blowing gas is switched from nitrogen to argon, and the P in the tapping molten steel is controlled to be 0.014%, and the C in the tapping molten steel is 0.08%, so as to prevent overoxidation of the molten steel. The temperature of the tapping molten stee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com