Transferring and furnace-entering device for refractory material and transferring and furnace-entering method for refractory material

A refractory material and furnace body technology is applied in the field of refractory material backward transport into the furnace device, which can solve the problems of low efficiency, high labor intensity and high breakage rate of refractory materials, and achieve high economic benefits, labor intensity reduction, and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

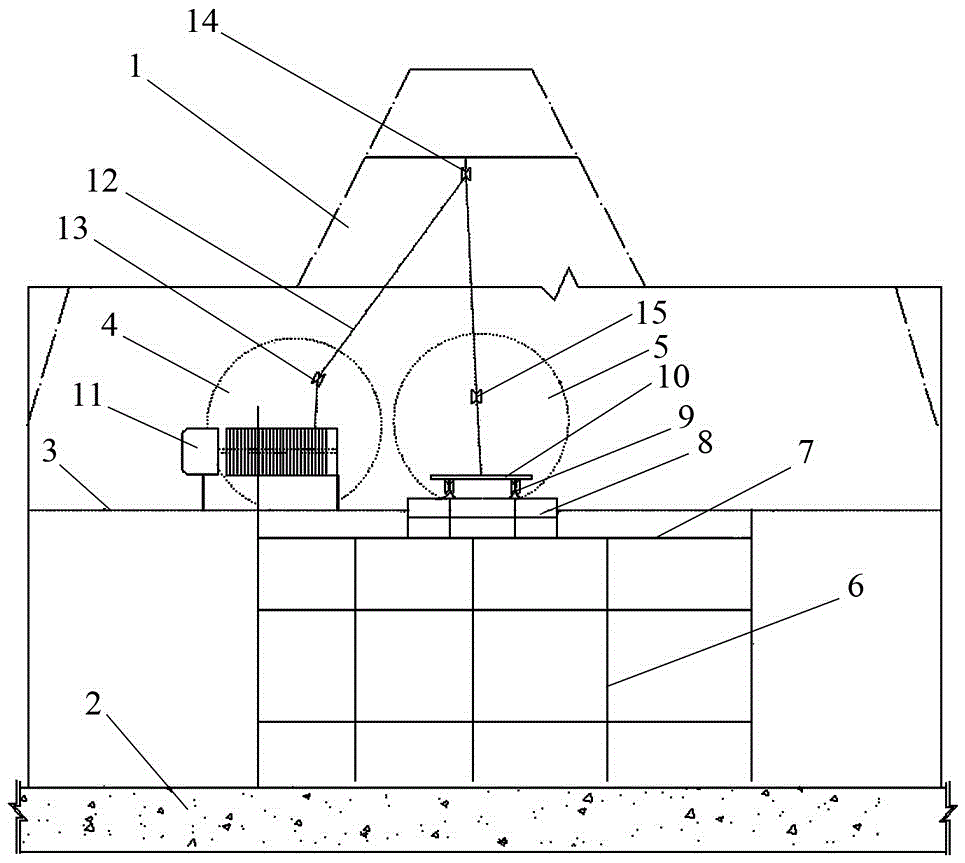

[0023] Embodiment 1: The refractory material is transported back into the furnace device.

[0024] Such as figure 1 As shown, the device of the present invention is provided with a casthouse platform 2 and a tuyere platform 3 on the outside of the body of furnace 1, the tuyere platform 3 is located above the casthouse platform 2, and the furnace body 1 above the tuyere platform 3 is provided with a first The first tuyere 4 and the second tuyere 5 are provided with a steel frame structure on the inner wall of the furnace body 1 below the second tuyere 5 .

[0025] A scaffold 6 is set up on the casthouse platform 2, and the top of the scaffold 6 is located below the tuyere platform 3. A working platform 7 is laid on the top of the scaffolding 6, and the working platform 7 is formed by laying 20 channel steel, with smooth surface and stable structure. A track platform 8 is arranged on the working platform 7, one end of the track platform 8 is fixedly installed on the working pl...

Embodiment 2

[0027] Embodiment 2: The method of transporting the refractory material back into the furnace.

[0028] A, scaffolding 6 is built on the casting yard platform 2 of body of heater 1, and the top of scaffolding 6 is positioned at the below of tuyere platform 3 of body of heater 1; Work platform 7 is laid on the top of scaffold 6 built, and work platform 7 is made of 20 channel steel is laid, the surface is smooth and the structure is stable.

[0029] b. Set up a track platform 8 on the laid work platform 7, one end of the track platform 8 is fixedly installed on the work platform 7, and the other end enters the inside of the furnace body 1 through the second tuyere 5 on the furnace body 1, and is fixed on the On the inner wall of the furnace body 1 opposite to the second tuyere 5; at the same time, a walking platform for people to walk is set up on the side of the track platform 8, so that construction personnel can enter and exit the furnace body 1 inside and outside.

[0030]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com