Hot-metal bottle combined cover and method thereof for adding and lifting cover

A technology for molten iron tanks and combined lids, which is applied to metal processing equipment, casting molten material containers, casting equipment, etc., can solve the problems of molten iron temperature loss, coke and hot air energy consumption increase, and reduce consumption, save energy, reduce Effects of Environmental Pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

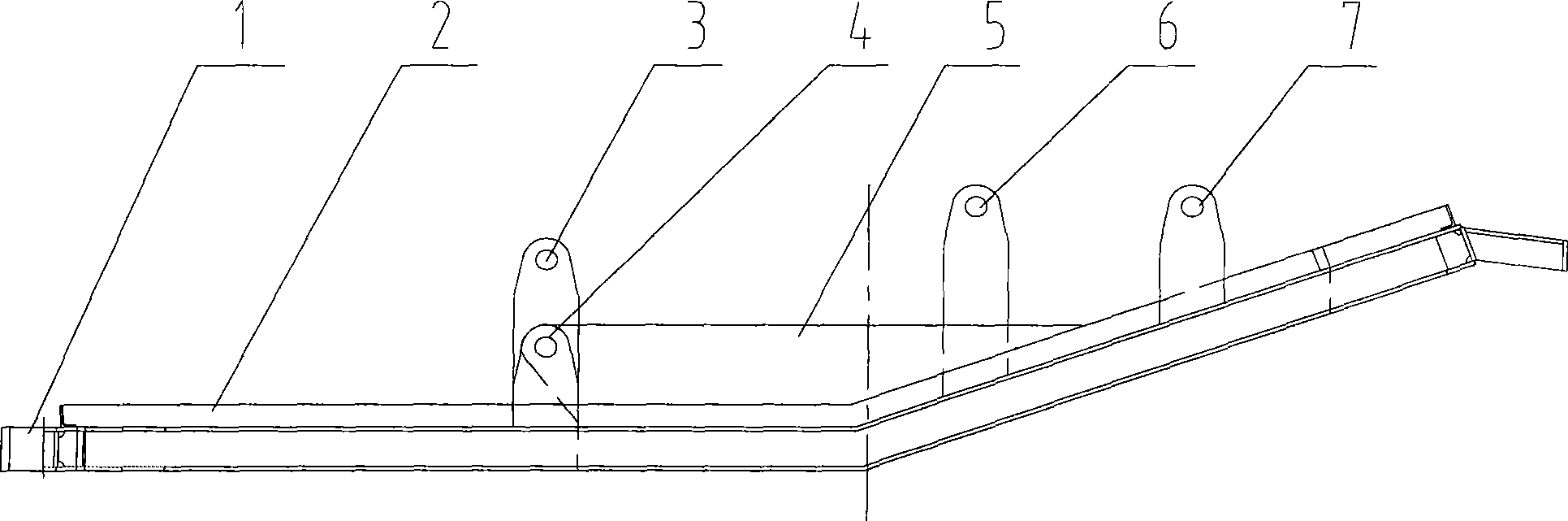

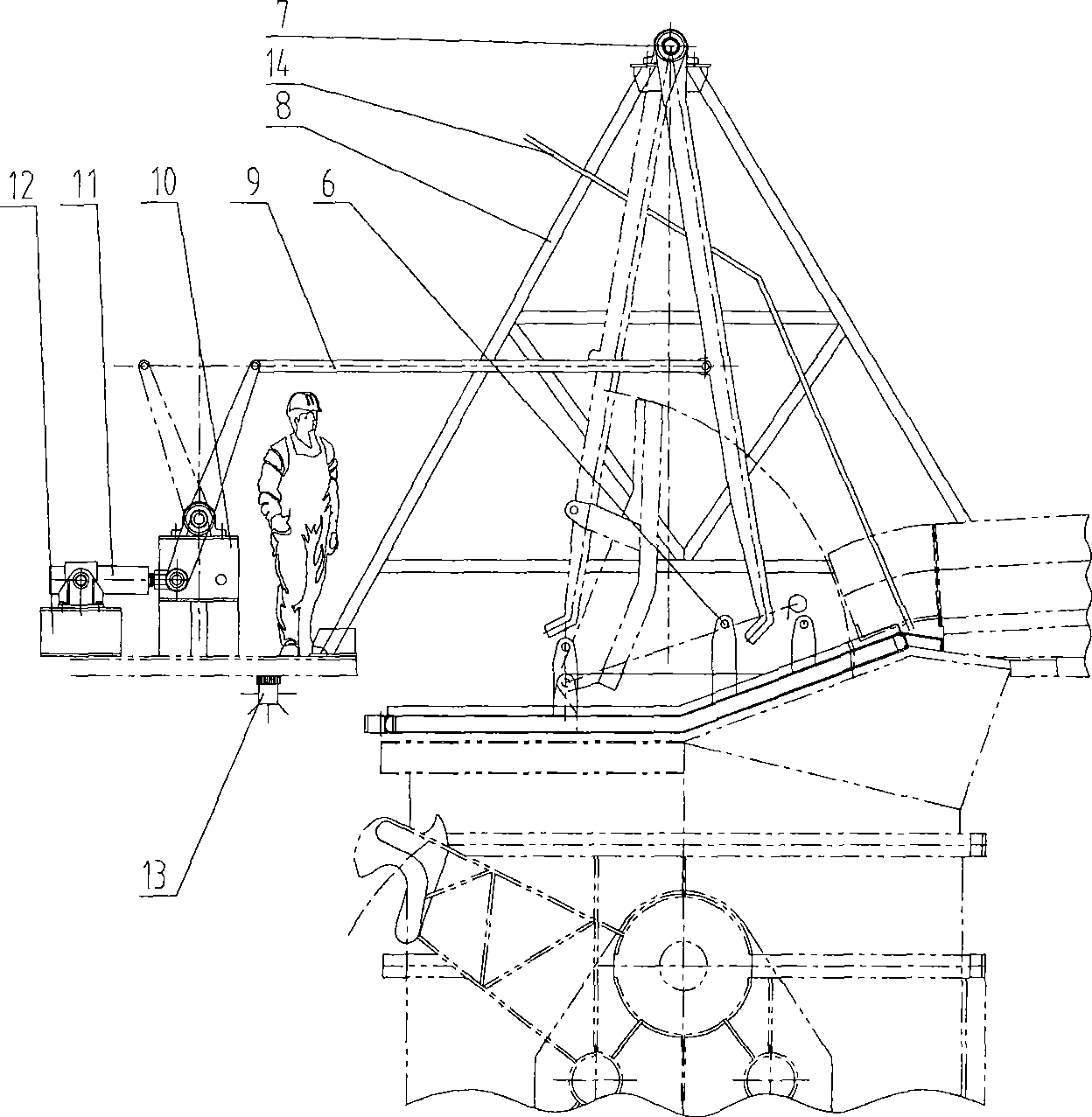

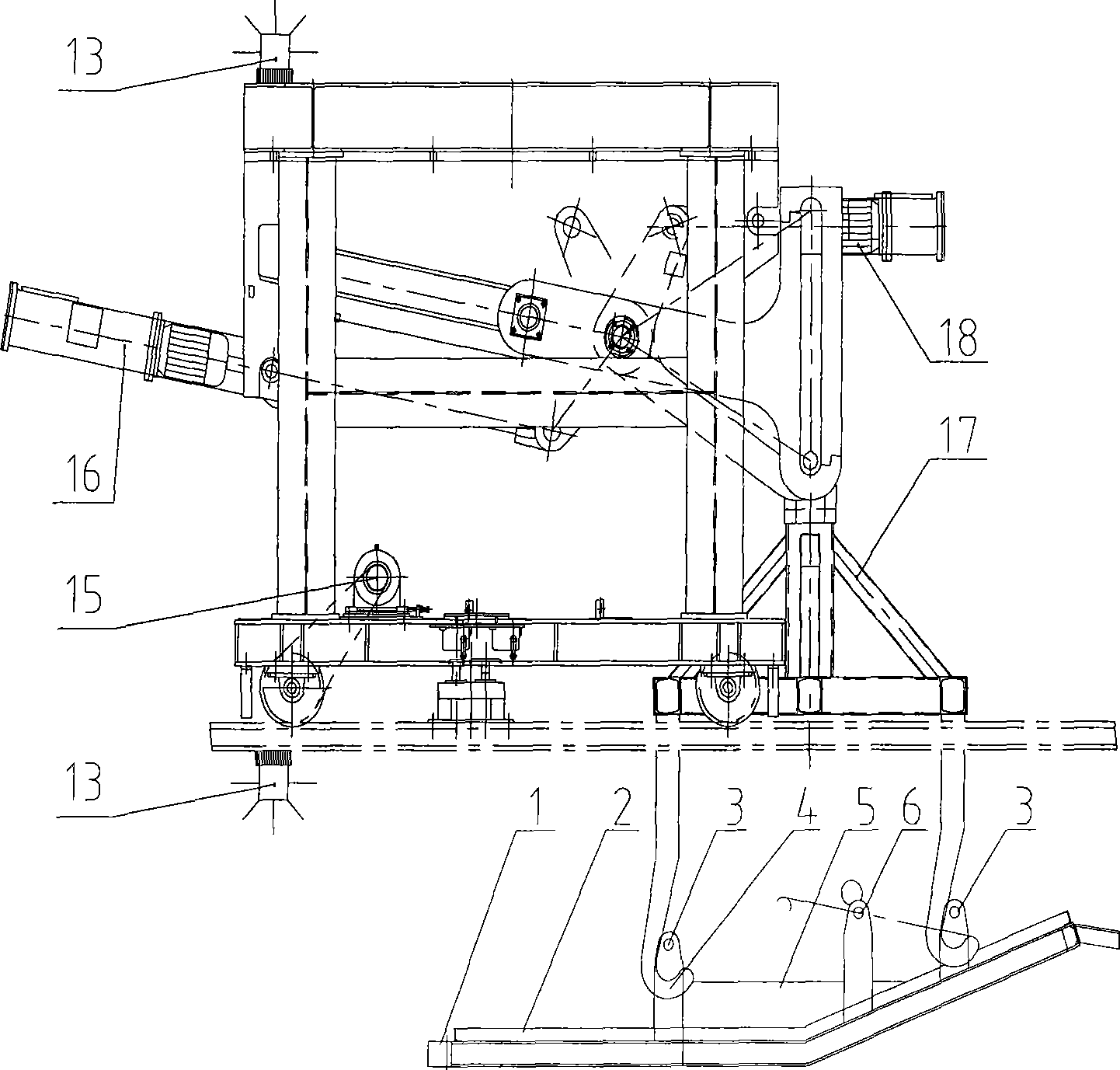

[0021] Figure 1 ~ Figure 3 It is a specific embodiment of the present invention.

[0022] The molten iron tank combination cover is composed of a positioning ring 1, a molten iron tank cover 2, a suspension ring 3, a hinge 4, an iron receiving nozzle cover 5 and a swing ring 6. The molten iron tank cover 2 and the iron receiving nozzle cover 5 are connected by a hinge 4. The entire combined cover Position by positioning ring 1 and the fixed pin on the ladle. The contact surface of the combined cover of the molten iron tank and the mouth of the molten iron tank realizes its function of heat insulation and heat preservation through refractory materials, and the refractory joint surface of the molten iron tank cover 2 and the molten iron tank cover 5 is automatically aligned and sealed.

[0023] The present invention can ensure that the lid 2 of the molten iron tank with the molten iron tank is ironed, and the full tank is transported by the random vehicle or the empty tank is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com