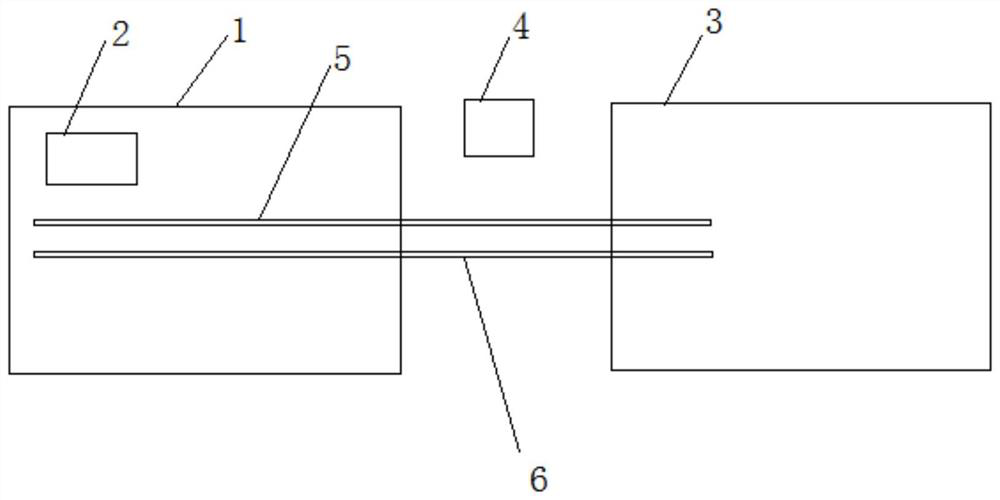

Blast furnace molten iron transportation system and blast furnace molten iron transportation method

A technology of blast furnace molten iron and transportation system, applied in blast furnace, blast furnace details, blast furnace parts and other directions, can solve the problems of reducing the number of online molten iron tanks, large number of online molten iron tanks, low operation efficiency of molten iron tanks, etc., and achieves equipment cost and energy efficiency. The effect of cost reduction, fewer tail tanks, and reduced quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

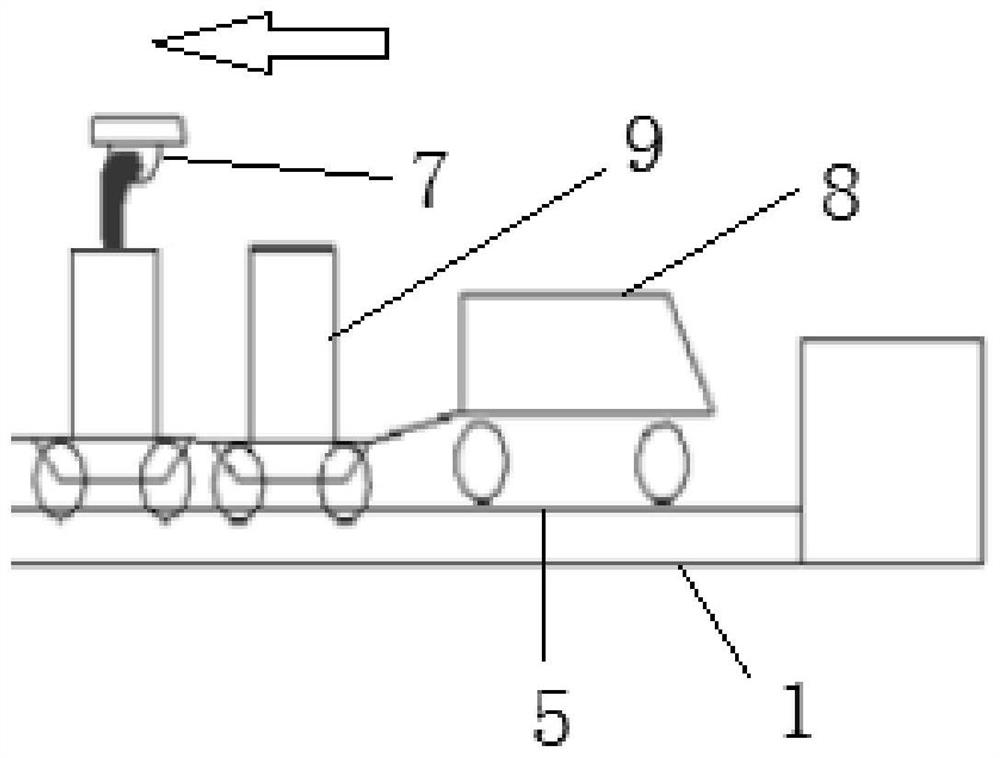

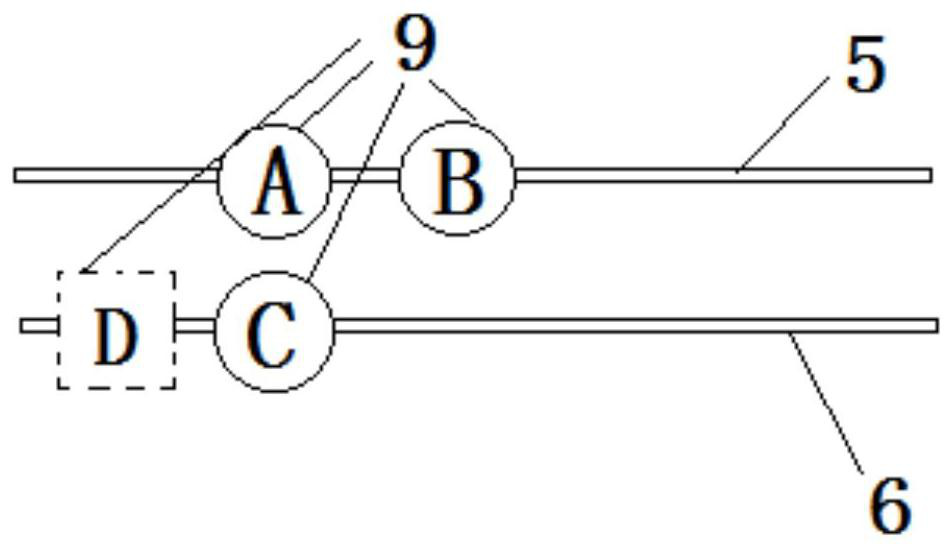

[0075] According to a preferred embodiment of the present invention, the method further includes: controlling the tractor 8 through the terminal to tow the corresponding molten iron tank 9 to carry out the alignment operation, and at the same time judging whether the alignment is successful according to the weight feedback of the molten iron weighing mechanism , and then send a signal of success or failure of alignment;

[0076] When the terminal receives the alignment success signal, the terminal controls the swing direction of the swing nozzle 7, and at the same time controls the blast furnace 2 to tap iron, so as to receive iron. During the iron receiving process, the terminal controls The tractor 8 carries out the work of advancing and transporting the molten iron tank 9 and replenishing the iron receiving unit.

[0077] In the above-mentioned preferred solution, the molten iron weighing mechanism judges whether the alignment position of the molten iron tank 9 is within th...

Embodiment 1

[0090] In this embodiment, a remote-controlled electric tractor 8 and a molten iron track scale without foundation pit are installed on the molten iron transportation line of the casthouse 1 under the blast furnace 2 to realize the safe top-flow dismantling operation of molten iron. Moreover, the electric tractor 8 can transport the heavy tanks that have reached the iron standard to the safe area outside the casting yard 1 through remote control during the tapping process of this trip, and then the connecting personnel will carry out the unloading operation of the heavy tanks, which effectively solves the problem. Previously, there was a problem that personnel could not enter casthouse 1 for top-flow unloading of heavy tanks. The molten iron track scale without foundation pit effectively solves the problem that the amount of molten iron loaded meets the standard, and at the same time effectively controls the problem that the amount of molten iron loaded exceeds the standard and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com