Blast furnace gravitational dust and ash removal device

A technology of gravity dust removal and blast furnace, applied in the direction of dust collector, etc., can solve the problems of gravity dust removal, environmental pollution, dust removal, etc., and achieve the effect of ensuring sealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

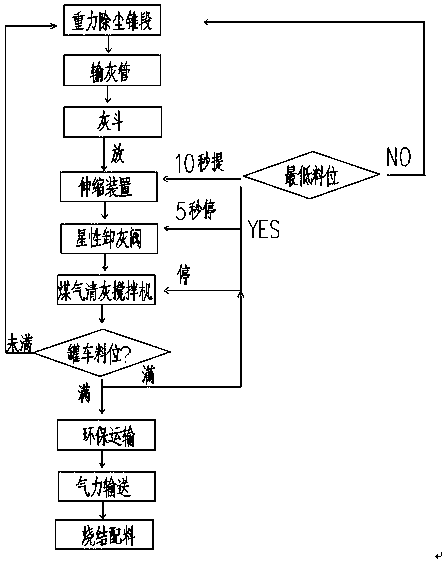

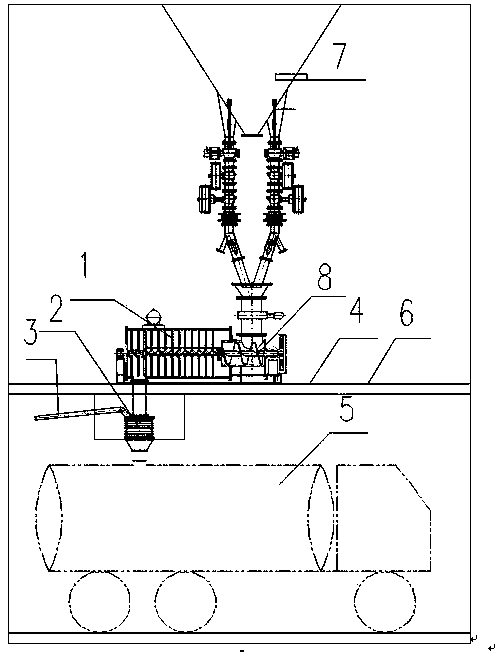

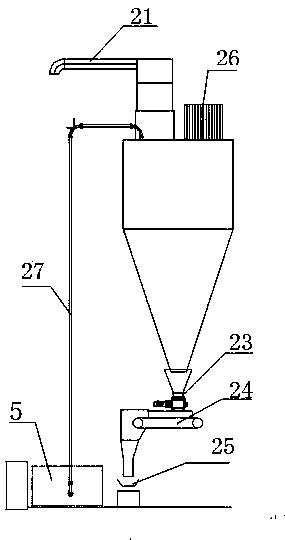

[0015] Embodiment 1: see figure 1 , a blast furnace gravity dedusting device, the dedusting device comprises a gas ash removal mixer 1, an electric telescopic device 2, a dust removal system pipe 3 in a blast furnace casting house, a left and right sliding track 4 of the electric telescopic device, a tank car 5, and a steel structure platform 6 , cone section tuning fork material level switch 7 and star-shaped ash unloading valve 8, the gas cleaning mixer 1 and left and right sliding rails 4 are set on the steel structure platform, and the bottom of the cone section tuning fork material level switch 7 is provided with a star-shaped Ash unloading valve 8, the dust removal system pipeline 3 of the blast furnace casthouse is set on the electric telescopic device 2, and the electric telescopic device 2 is located below the steel structure platform 6. The interior of the telescopic device is DN150 seamless steel pipe, and the external The cage is sealed, and the upper part of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com