Overturn type top dust cover

A dust-removing hood and flip-type technology, applied in the direction of dust collectors, can solve the problems that the disintegrator cannot work under the rail beam, the structure is complicated, and the connection is not good, so as to improve the environment in front of the furnace, improve the working conditions, and reduce the work intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

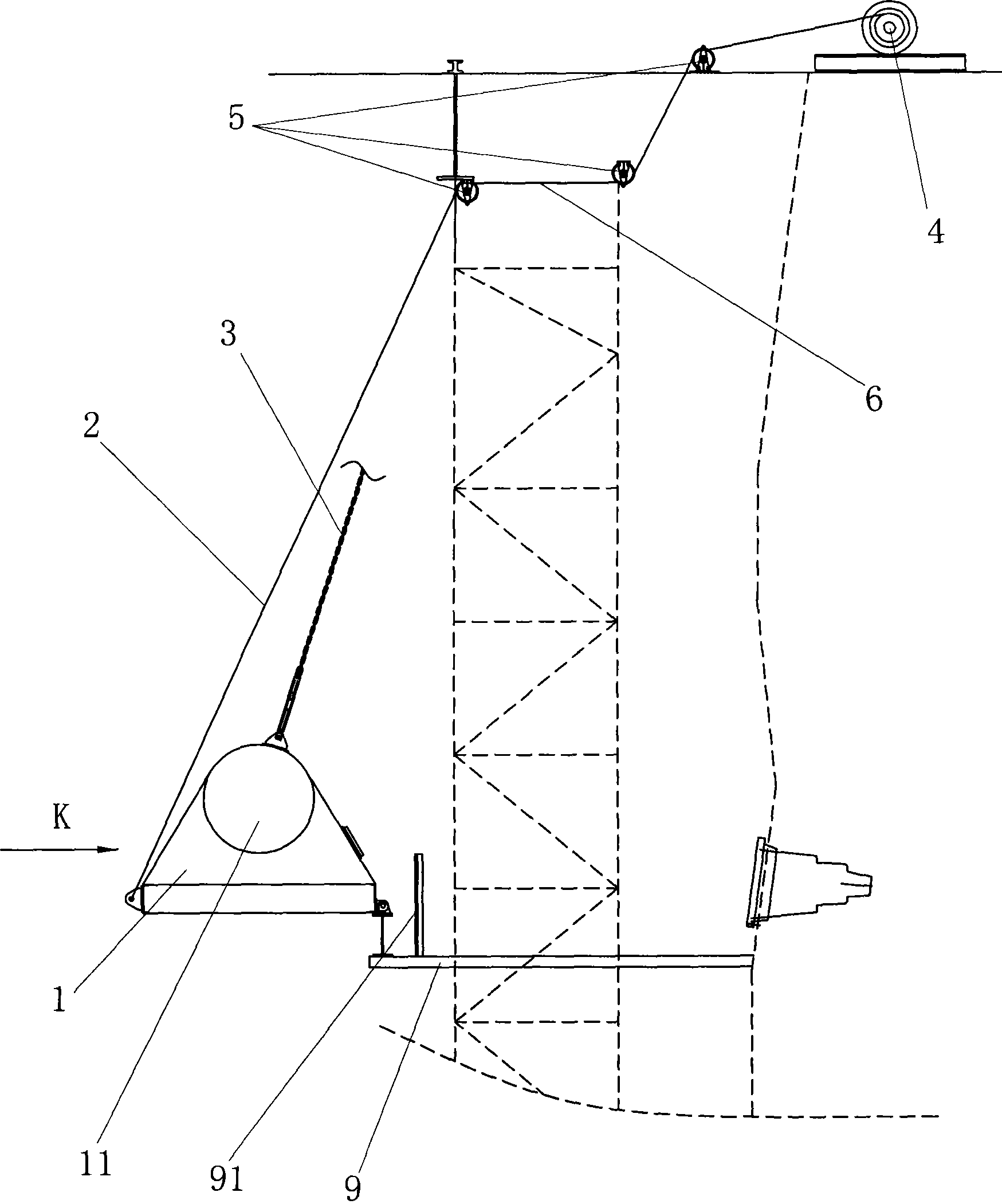

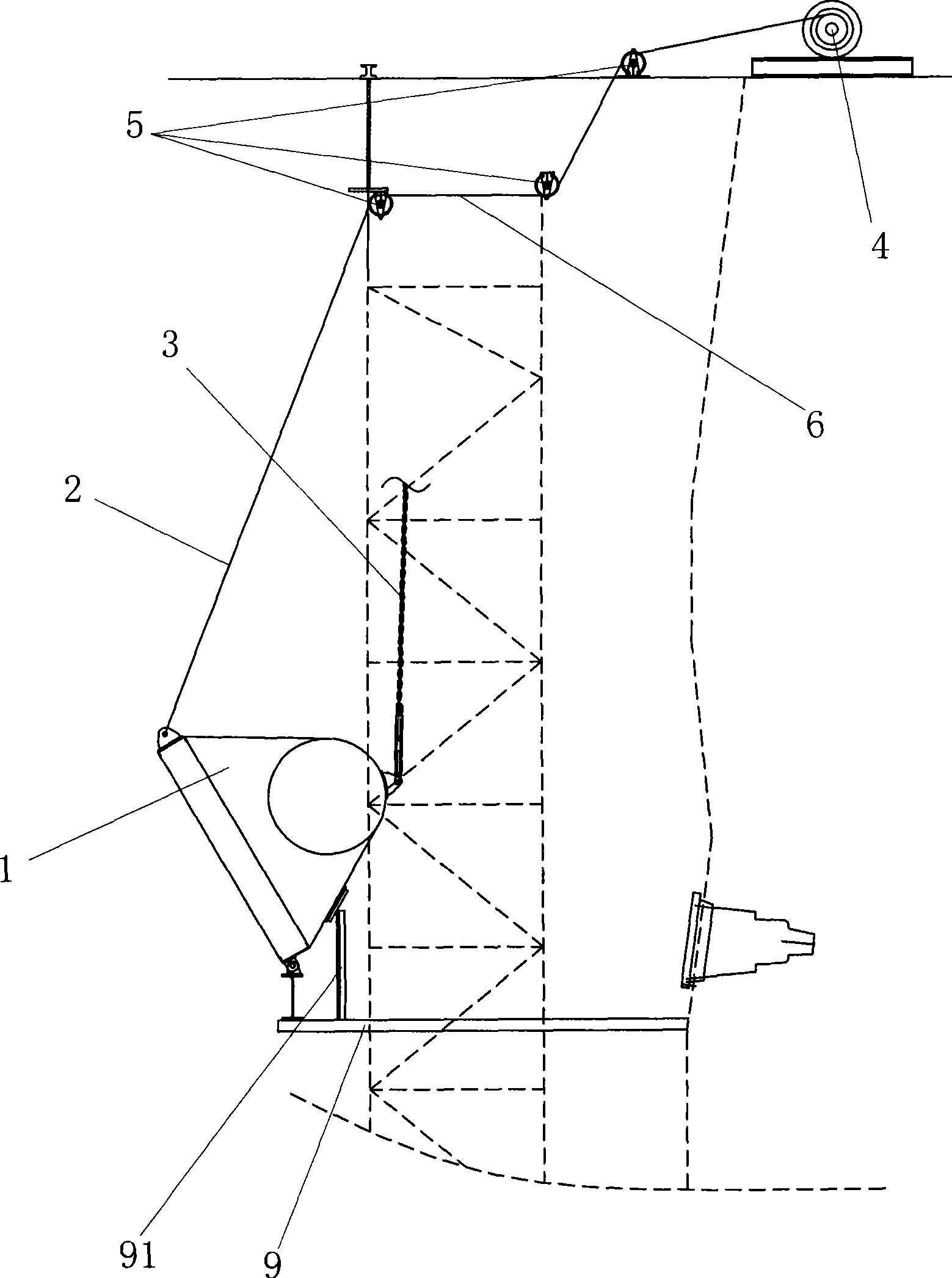

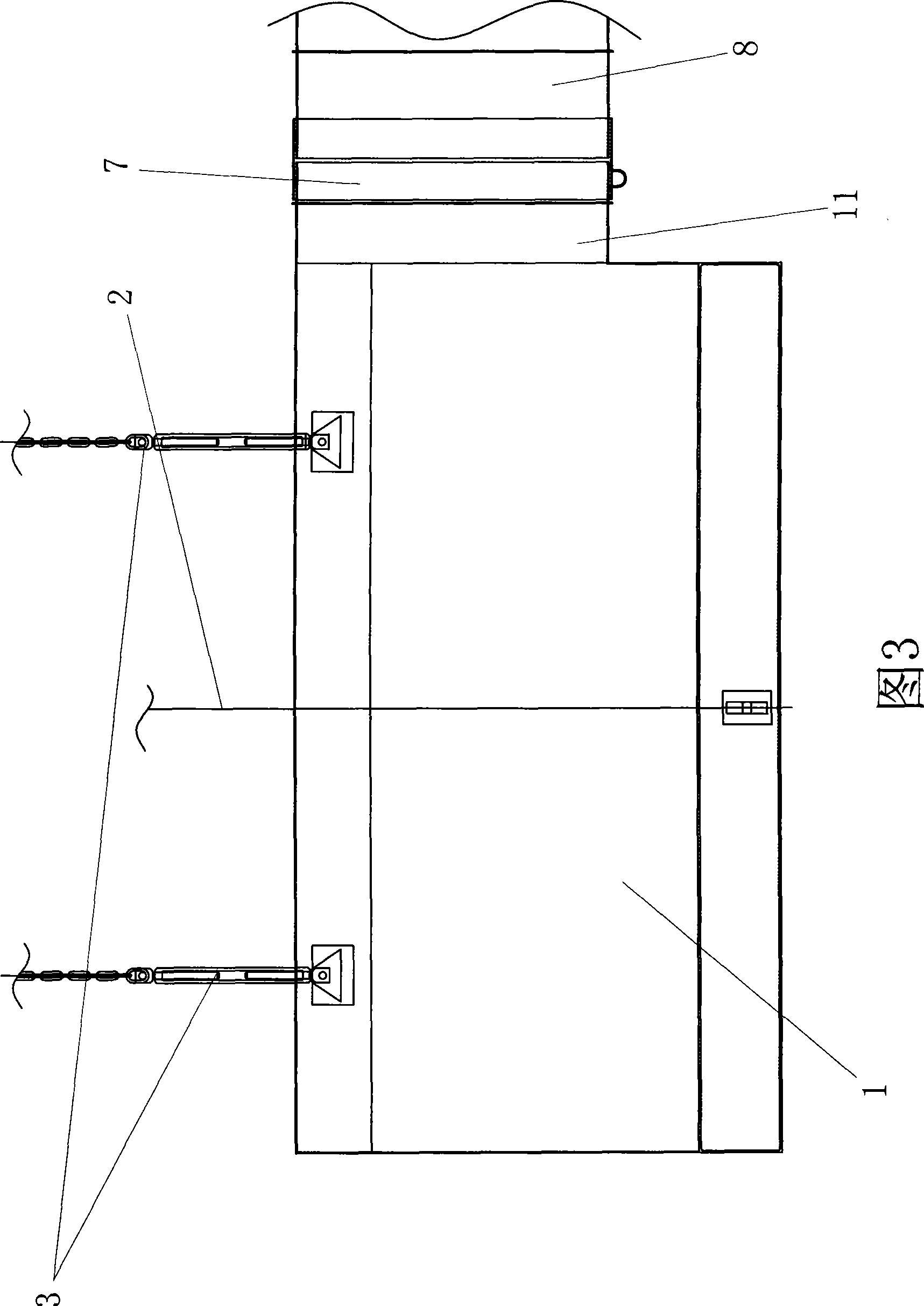

[0027] like figure 1 , figure 2 , as shown in Figure 3, a flip-type top dust removal cover, the flip-type top dust removal cover includes a cover body 1, the cover body 1 is arranged above the main iron ditch of the casting plant, and the rear side of the cover body 1 is pivotally connected On the edge of the tuyere platform 9, a sling 2 is provided on the front side of the cover body 1 to lift the cover body 1 and make it turn around the rear pivot shaft; 11 can communicate with a dust removal pipeline 8.

[0028] From the above, when the iron is tapped normally, such as figure 1 As shown, the cover body 1 is turned over to cover the position above the main iron channel, and the outlet 11 is connected with the dust removal p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com