Totally-closed dust removal cover for casting house in front of blast furnace

A fully-enclosed, dust-removing hood technology, applied in dust collectors, process efficiency improvement, discharge devices, etc., can solve problems such as blast furnace dust pollution in casthouses, meet on-site production needs, improve casthouse environment, and structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

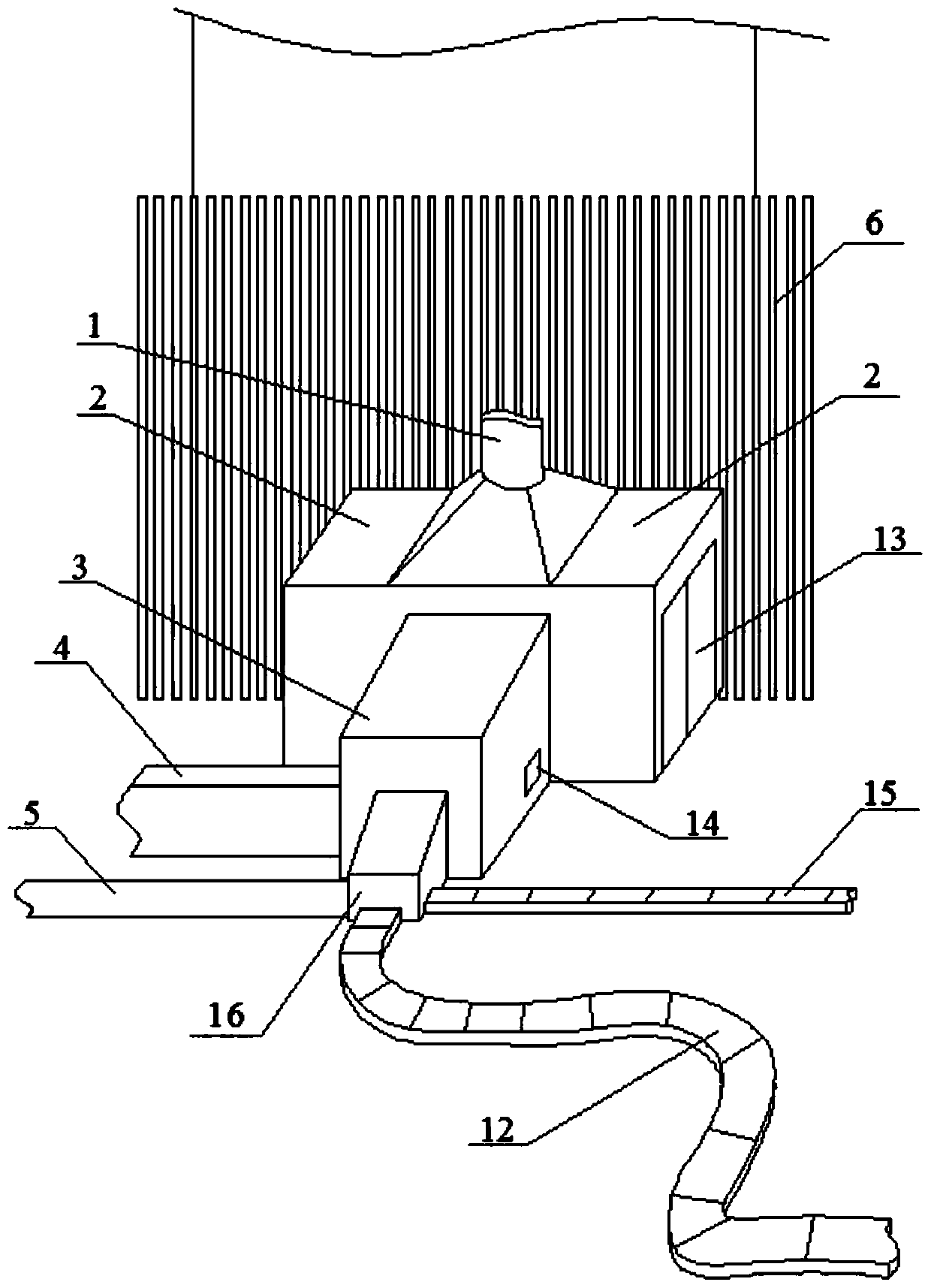

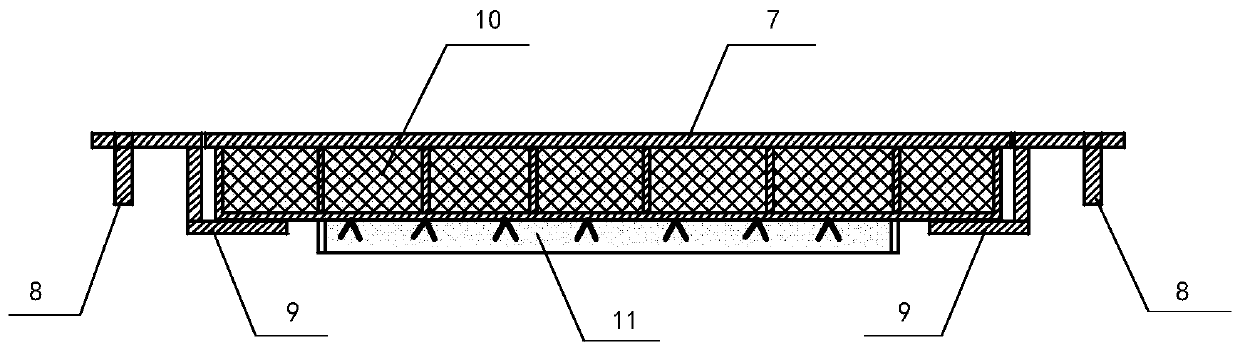

[0021] The invention discloses a fully enclosed dust removal hood in front of the blast furnace casthouse, such as figure 1 As shown, it includes a general dust cover covering the main ditch in the casthouse to seal the main ditch and prevent the spread of smoke and dust, and covering the iron ditch 12, slag ditch 15 and emergency molten iron flow channel 5 in the casthouse for A cover assembly that is airtight and prevents the diffusion of smoke and dust; the total dust removal cover and each set of the cover assembly are detachable and sealed.

[0022] The total dust removal cover includes a main ditch dust removal cover, an intermediate dust removal cover 3 and a skimmer dust removal cover 16 which are connected in sequence. The main ditch dust cover covers the top of the main ditch near the taphole, the middle dust cover 3 covers the top...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com