System for replacing blast furnace activity main trough and replacement method therefor

A replacement method, the technology of the main iron trough, applied in the field of metallurgical industry, can solve the problems of high technical requirements for workers, large casthouse platform space, long working time, etc., so as to save investment, improve production efficiency and save working time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

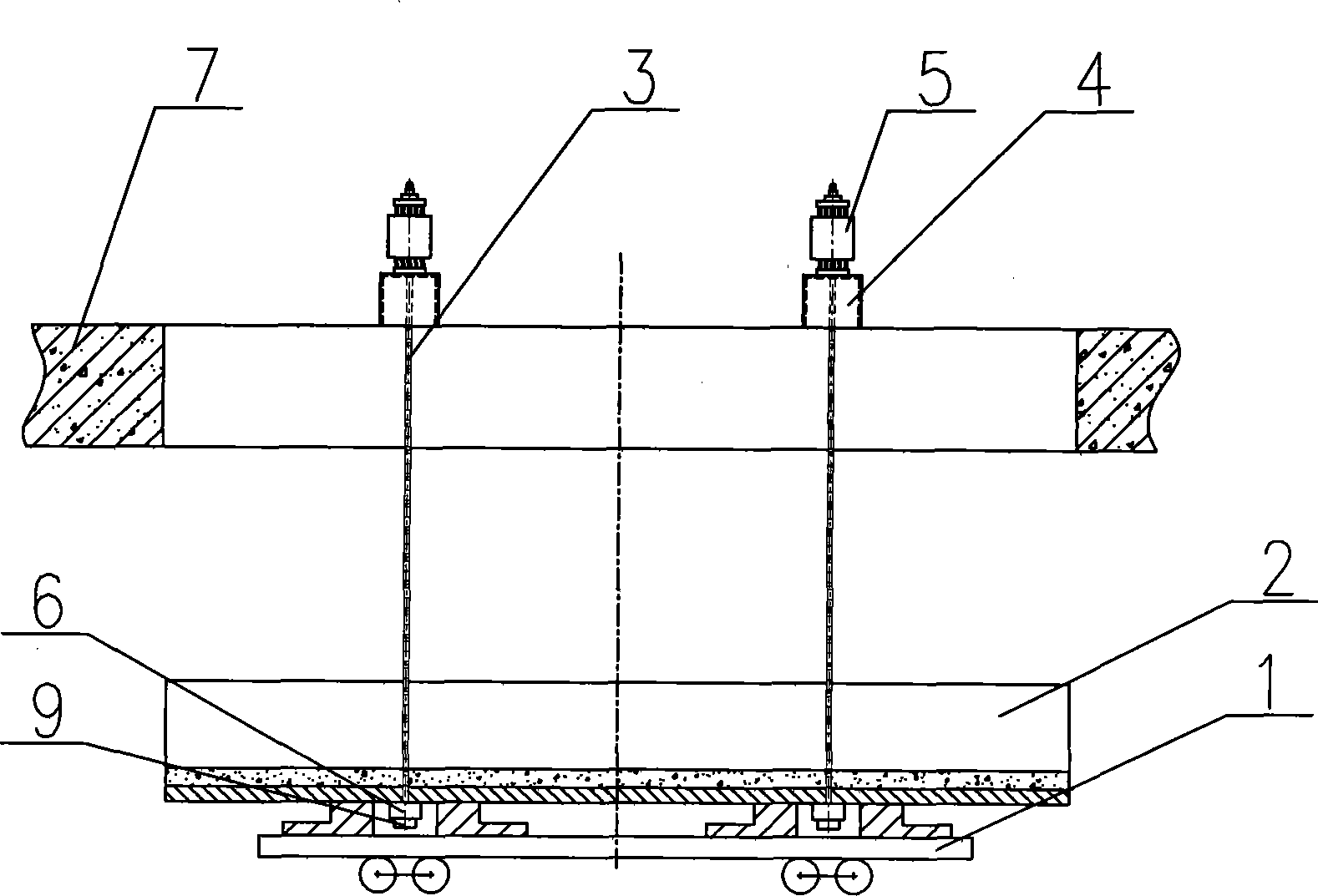

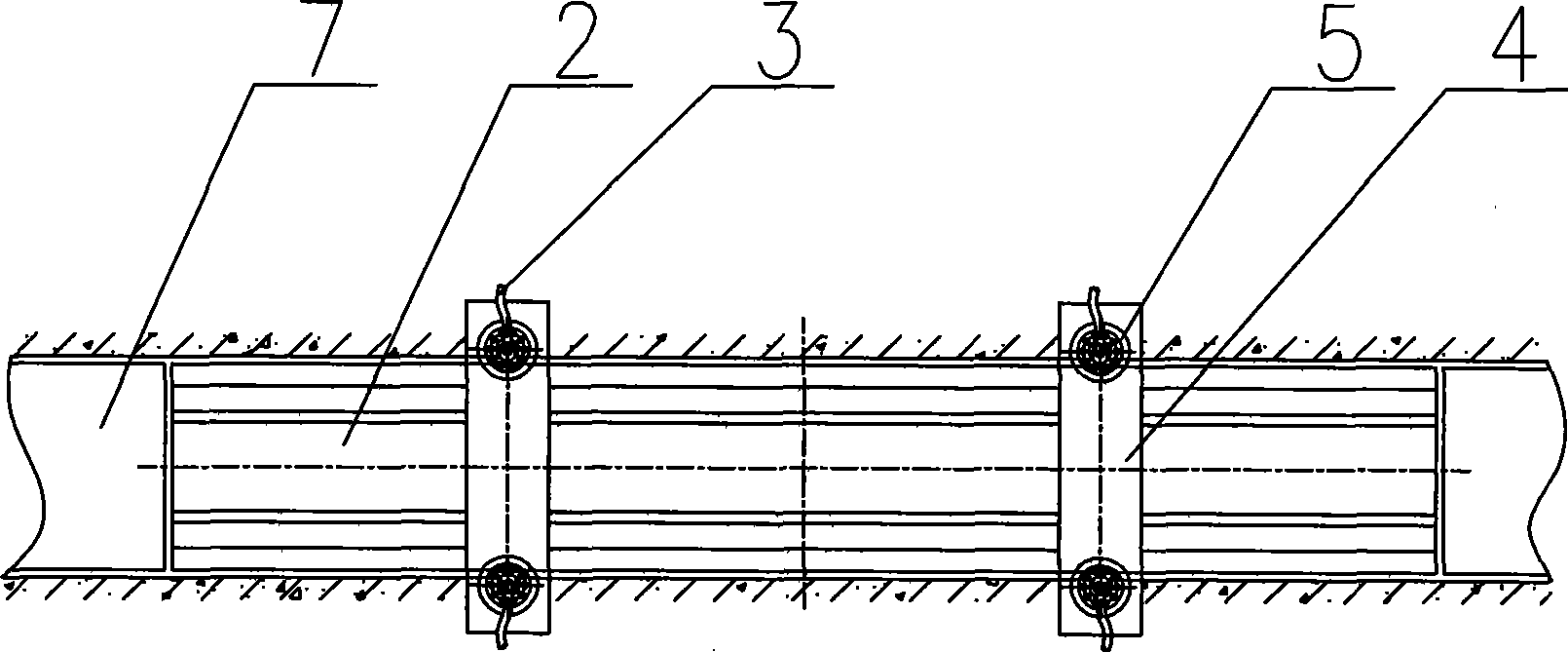

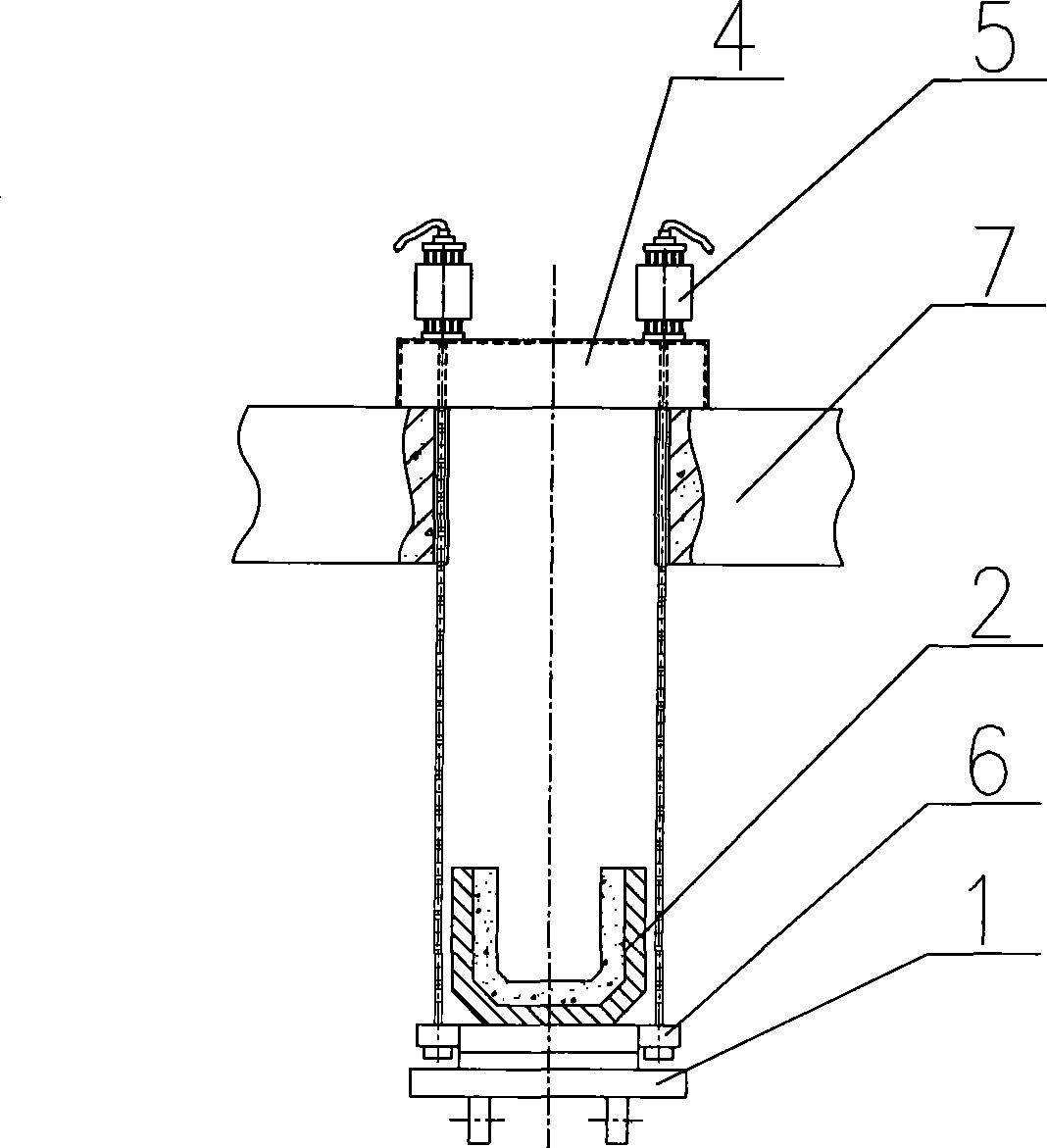

[0029] Embodiment 1: as Figure 1 to Figure 5 As shown, a blast furnace movable main iron channel replacement system, the system includes a casthouse platform 7 for transporting the main iron channel; a support beam 4; a lifter 5; a hoisting cable 3; a lifting beam 6; the lifting beam 6 The two ends of each are provided with hoisting cable through holes 12; flatbed truck 1; connection plate 9, and bolts 10 and nuts 11 that are matched with the connection plate 9.

[0030] When it is necessary to replace the movable main iron trough of the blast furnace, the components included in the above-mentioned system are operated according to the following steps: (1) two support beams 4 are installed on the casthouse platform 7; (2) two supports of each support beam 4 (3) One end of the hoisting rope 3 is clamped in the hoisting device 5, and the other end passes through the hoisting rope through hole 12 of the hoisting beam 6 so as to connect with the connecting plate 9 Fasten the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com