Dust removing device for blast furnace casting house

A technology for dust removal device and blast furnace tapping, which is applied in the direction of dust collector, smoke removal, discharge device, etc., can solve the problems of blast furnace production environment pollution, increased gap between cover plate and support device, and inability to achieve sealing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

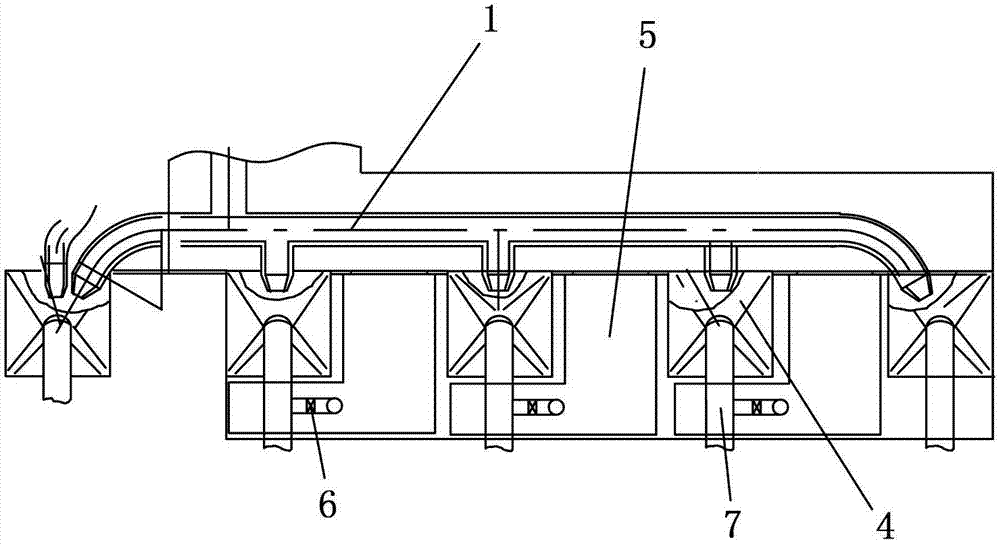

[0024] The core of the present invention is to provide a dedusting device for a blast furnace casting yard, so as to realize the collection of smoke and dust and the efficient dedusting effect of the inclined iron ditch.

[0025] In order for those skilled in the art to better understand the present invention, the present invention will be described in detail below with reference to the accompanying drawings and embodiments, wherein the same reference numerals always refer to the same components.

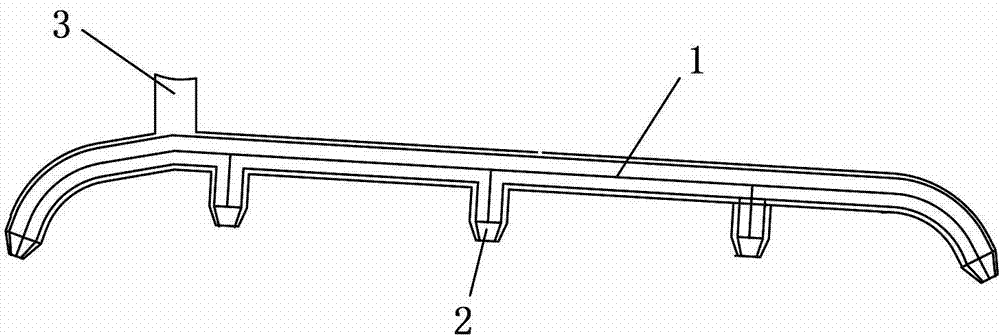

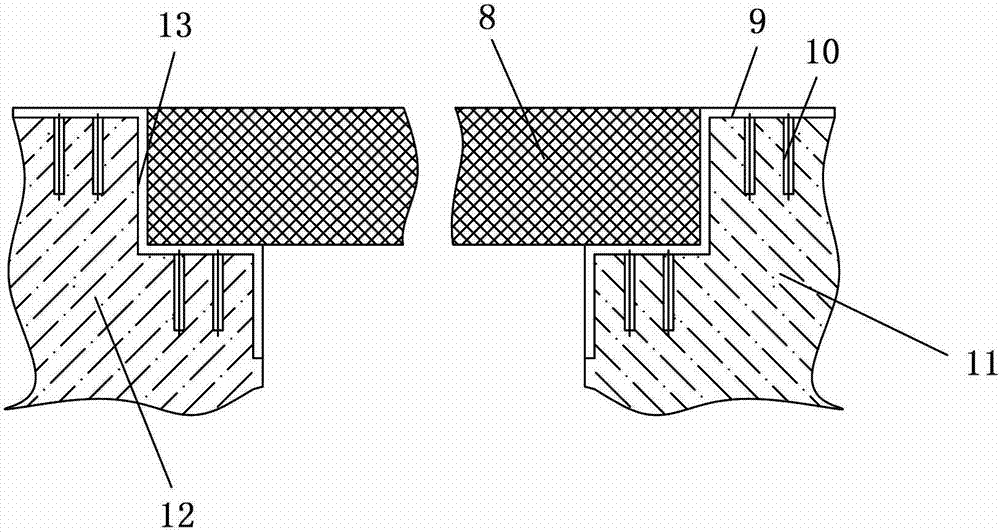

[0026] in, figure 1 It is a schematic structural diagram of a flowing iron ditch according to an embodiment of the present invention; figure 2 is a cross-sectional view of a portion of a dust removal device according to an embodiment of the present invention; image 3 Yes figure 2 The schematic diagram of the smoke and dust collection channel of the flow iron ditch of the dust removal device shown; Figure 4 is an overall layout diagram of a dust removal device according to an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com