Rapid molten iron conveying method and device combination between interfaces of molten iron and molten steel

A molten iron and interface technology, applied in industrial buildings and other fields, can solve problems such as long operation time, increased investment, and long railway lines

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

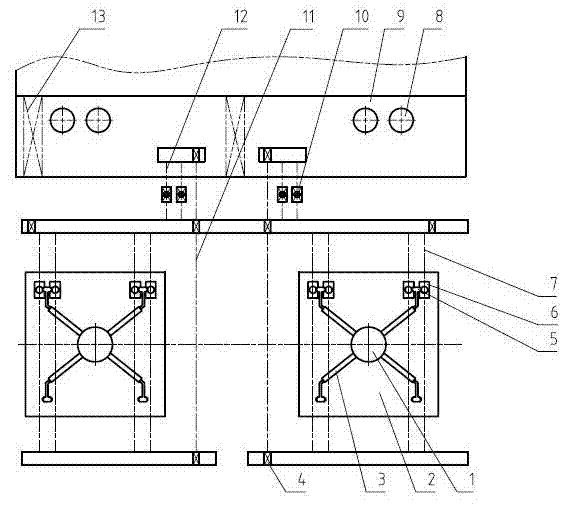

[0058] The combination of equipment between molten iron and molten steel interface, such as figure 1 As shown, it includes blast furnace 1, blast furnace casthouse 2, molten iron transportation unit 6, molten iron transportation line (7, 11, 12), converter 8,

[0059] The molten iron transportation line is arranged between the center line of blast furnace 1 and the center line of converter 8; blast furnace casting house 2 is located at the lower part of blast furnace 1, and molten iron transportation line 7 is arranged on the side of blast furnace casting house 2;

[0060] From the blast furnace casting yard 2 to the converter charging span 9, there is at least one discontinuity in the molten iron transportation line (7, 11, 12), and the molten iron transportation line is divided into the molten iron transportation line 7 on the blast furnace side and the molten iron transportation line on the converter side 12. The molten iron transportation line 7 on the blast furnace side i...

Embodiment 2

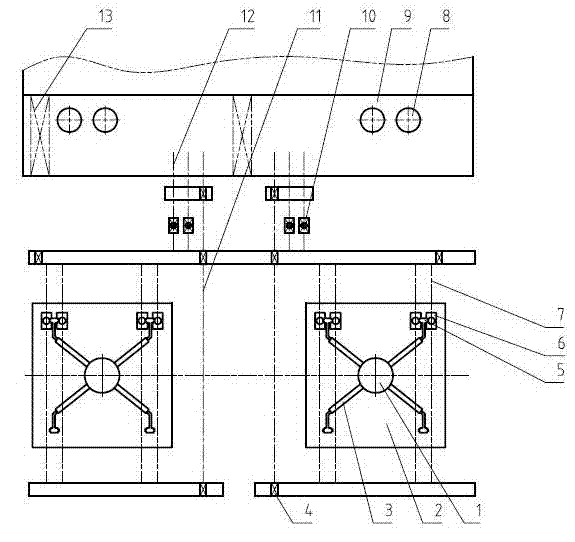

[0069] Others are as embodiment 1, the difference is that,

[0070] Such as figure 2 As shown, the molten iron desulfurization station 10 is arranged outside the charging bay of the converter workshop, a transition device 4 is provided between the charging bay of the converter workshop and the molten iron desulfurization station 10, and a transition device 4 is provided at the end of the molten iron transportation line on the side of the blast furnace away from the converter, A separate molten iron return travel line 11 is set outside the molten iron transport line.

[0071] The molten iron transportation unit 6 travels to the molten iron desulfurization station 10 for desulfurization operation of the molten iron. After desulfurization, the molten iron transportation unit 6 travels to the charging bay of the converter workshop, and waits for the molten iron in the molten iron tank to be loaded into the converter 8 by the converter charging span crane 13 .

[0072] The molten...

Embodiment 3

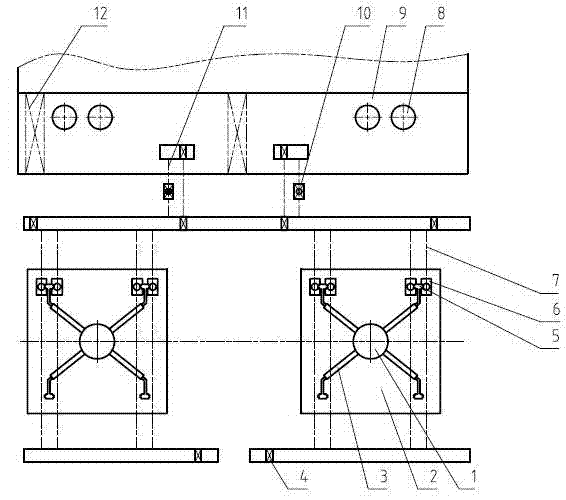

[0074] Others are the same as embodiment 1, the difference is that

[0075] Such as image 3 As shown, a transition device 4 is provided in the charging span 9 of the converter workshop, and no separate molten iron return travel line 11 is provided. The transport unit 6 filled with molten iron in the charging span 9 moves to another molten iron transport line 12 near the converter without a desulfurization station through the transition device 4 in the span, and waits for the last molten iron transport unit 6 filled with molten iron After moving to the desulfurization station 10 through the transition device 4, the waiting molten iron transport units 6 return to the casthouse 2 respectively through the transition device 4, and are positioned to wait for receiving molten iron.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com