Small-middle blast-furnace casting house mill building construction system

A blast furnace casting and casthouse technology, applied to blast furnaces, blast furnace details, blast furnace components, etc., can solve problems such as air pollution, low heat transfer efficiency, and lack of airflow organization, so as to improve the working environment and heat transfer efficiency , the effect of small mechanical ventilation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to meet the dual requirements of the internal post environment of the small and medium-sized blast furnace casthouse workshop and the fugitive emission concentration of external smoke and dust, it is necessary to adopt a closed workshop structure, optimize ventilation and dust removal measures, and reasonably organize the airflow direction of dust-laden high-temperature flue gas in order to improve Improve the ventilation and heat exchange effect in the factory building, improve the smoke collection rate, and prevent the smoke and dust from escaping.

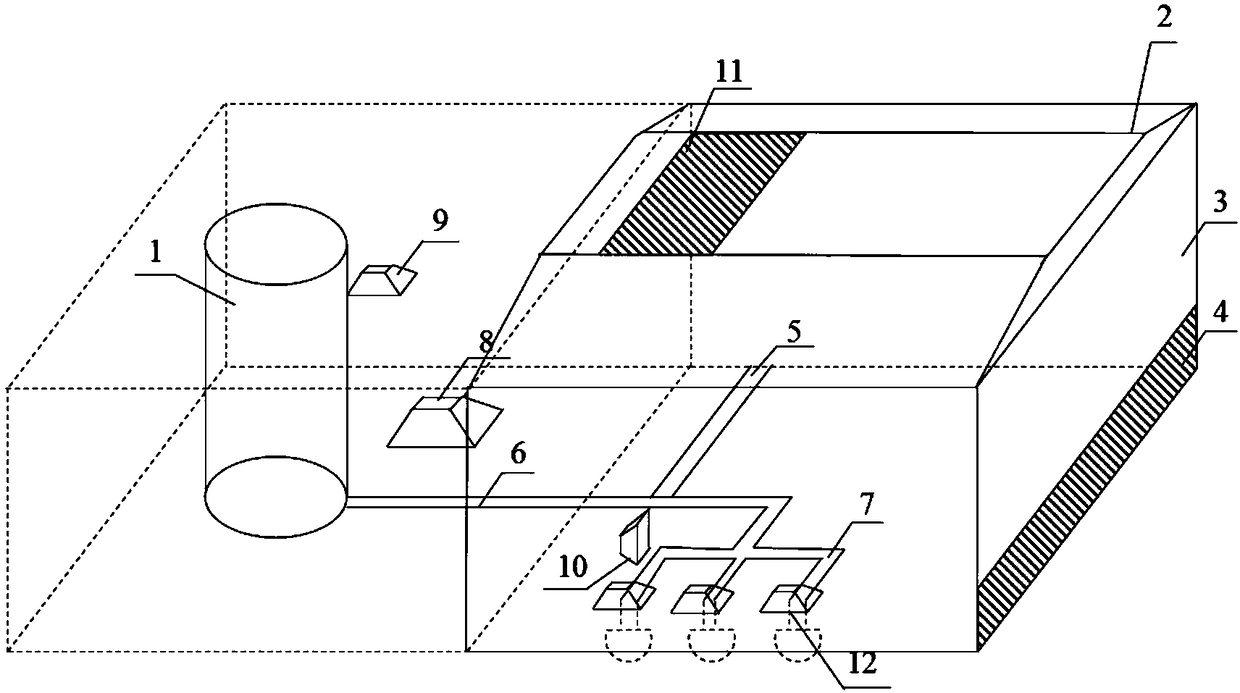

[0031] Such as figure 1 As shown, a small and medium blast furnace casthouse structure system includes a workshop structure, a ventilation and dust removal system and a medium and small blast furnace casthouse structure; the workshop structure includes a workshop roof 2 and a plurality of enclosures 3, and the workshop structure is closed, and the workshop The roof 2 is a non-sinking structure; the ventilation an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com