Producing technology of silver-liner double-deck glass cup

A production process and glass technology, which is applied in glass forming, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of easy bursting or cracks in the finished double-layer glass, waste of financial and material resources, and weak resistance to beating. Achieve the effect of not easy to burst, promote detoxification and health, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

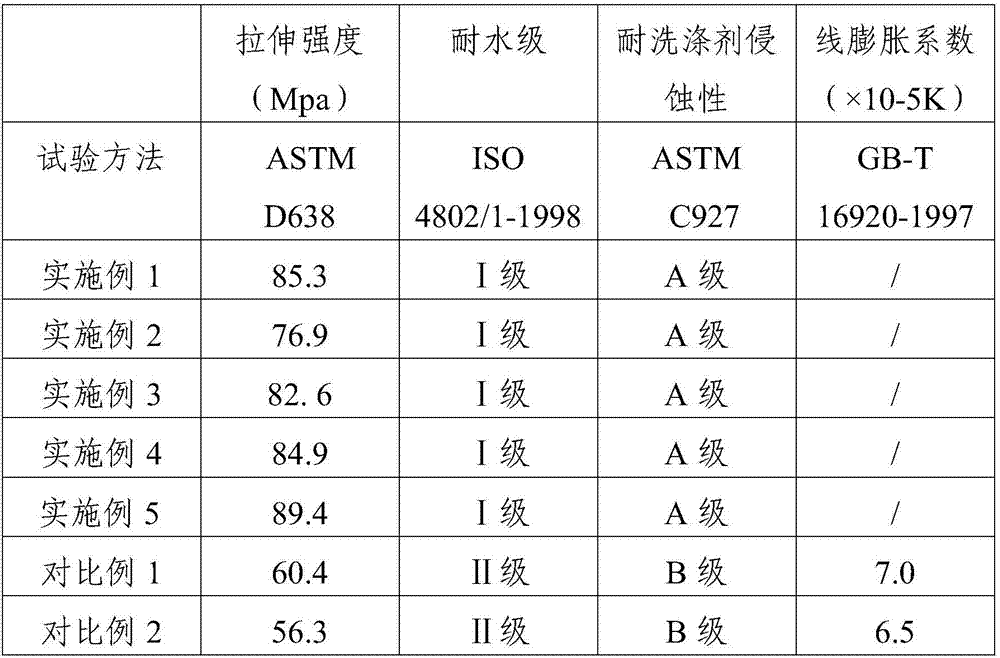

Examples

Embodiment 1

[0031] A production process of a silver liner double-layer glass, comprising the following steps:

[0032] (1) Preparation of high borosilicate crystal glass tube:

[0033] ①Ingredients: Weigh the raw materials of each component according to the following formula, 63 parts of quartz sand, 8 parts of boron oxide, 5 parts of boric acid, 8 parts of aluminum hydroxide, 2 parts of calcite, 2.5 parts of linden powder, 0.2 parts of ammonium fluorosilicate, chlorine 1.3 parts of sodium chloride, 0.1 part of lanthanum oxide, 0.8 part of cerium oxide, and 10 parts of broken glass are added into a mixer and mixed evenly to make a mixture;

[0034] ② Melting material: put the mixed material into the kiln furnace and melt it at a high temperature of 1600°C;

[0035] ③Molding: pour the melted glass batch material on the preheated glass tube mold, and then immediately transfer it to the annealing cellar for annealing. The annealing temperature is 520°C and the annealing time is 1.5h, and th...

Embodiment 2

[0043] A production process of a silver liner double-layer glass, comprising the following steps:

[0044] (1) Preparation of high borosilicate crystal glass tube:

[0045] ①Ingredients: Weigh the raw materials of each component according to the following formula, 60 parts of quartz sand, 10 parts of boron oxide, 8 parts of boric acid, 5 parts of aluminum hydroxide, 4 parts of calcite, 3 parts of linden powder, 0.3 parts of ammonium fluorosilicate, chloride Add 0.5 parts of sodium chloride, 0.2 parts of cerium oxide, 0.3 parts of strontium oxide, and 13 parts of cullet into a mixer to mix and stir evenly to make a mixture;

[0046] ② Melting material: Put the mixed material into the kiln furnace and melt it at a high temperature of 1500°C;

[0047] ③Forming: pour the melted glass batch material on the preheated glass tube mold, and then immediately transfer it to the annealing cellar for annealing. The annealing temperature is 540°C, and the annealing time is 2 hours. The abo...

Embodiment 3

[0055] A production process of a silver liner double-layer glass, comprising the following steps:

[0056] (1) Preparation of high borosilicate crystal glass tube:

[0057] ①Ingredients: Weigh the raw materials of each component according to the following formula, 75 parts of quartz sand, 12 parts of boron oxide, 4 parts of boric acid, 6 parts of aluminum hydroxide, 1 part of calcite, 2 parts of linden powder, 0.6 parts of ammonium fluorosilicate, chlorine Add 0.3 parts of sodium chloride, 0.5 to 0.9 parts of rare earth metal oxides, and 15 parts of cullet, and add them into the mixer and mix them evenly to make a mixture;

[0058] ② Melting material: put the mixture into the kiln furnace and melt it at a high temperature of 1400°C;

[0059] ③Molding: pour the melted glass batch material on the preheated glass tube mold, and then immediately transfer it to the annealing cellar for annealing. The annealing temperature is 560°C, and the annealing time is 3 hours. The above-ment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com