Electric heating pipe for heating liquid

An electric heating tube and liquid technology, which is applied in the field of electric heating tubes, can solve the problems of large temperature difference, leakage of electricity, danger of electric shock to people in the liquid, etc., and achieves the effects of not easy to burst, preventing device bursting, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

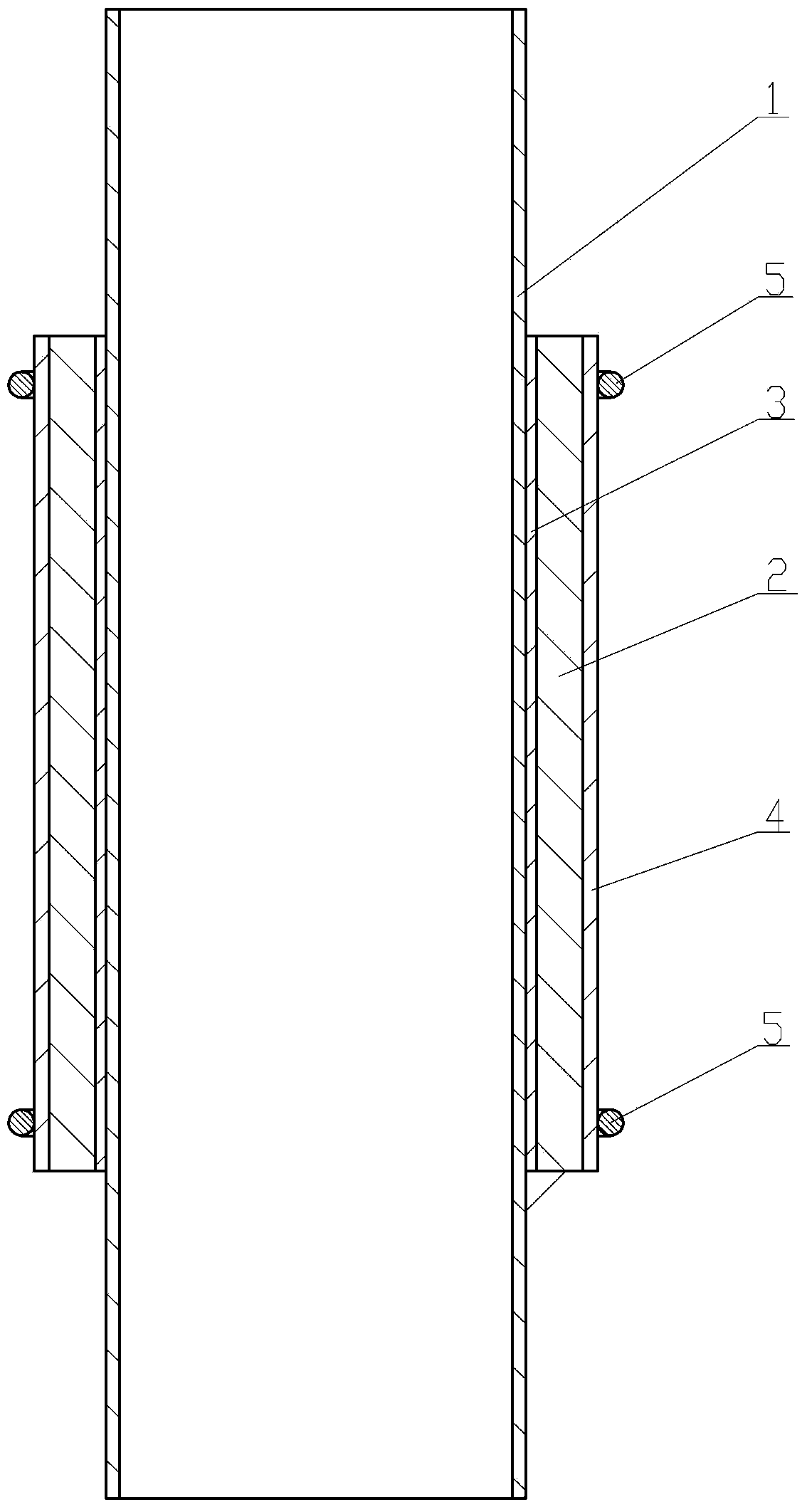

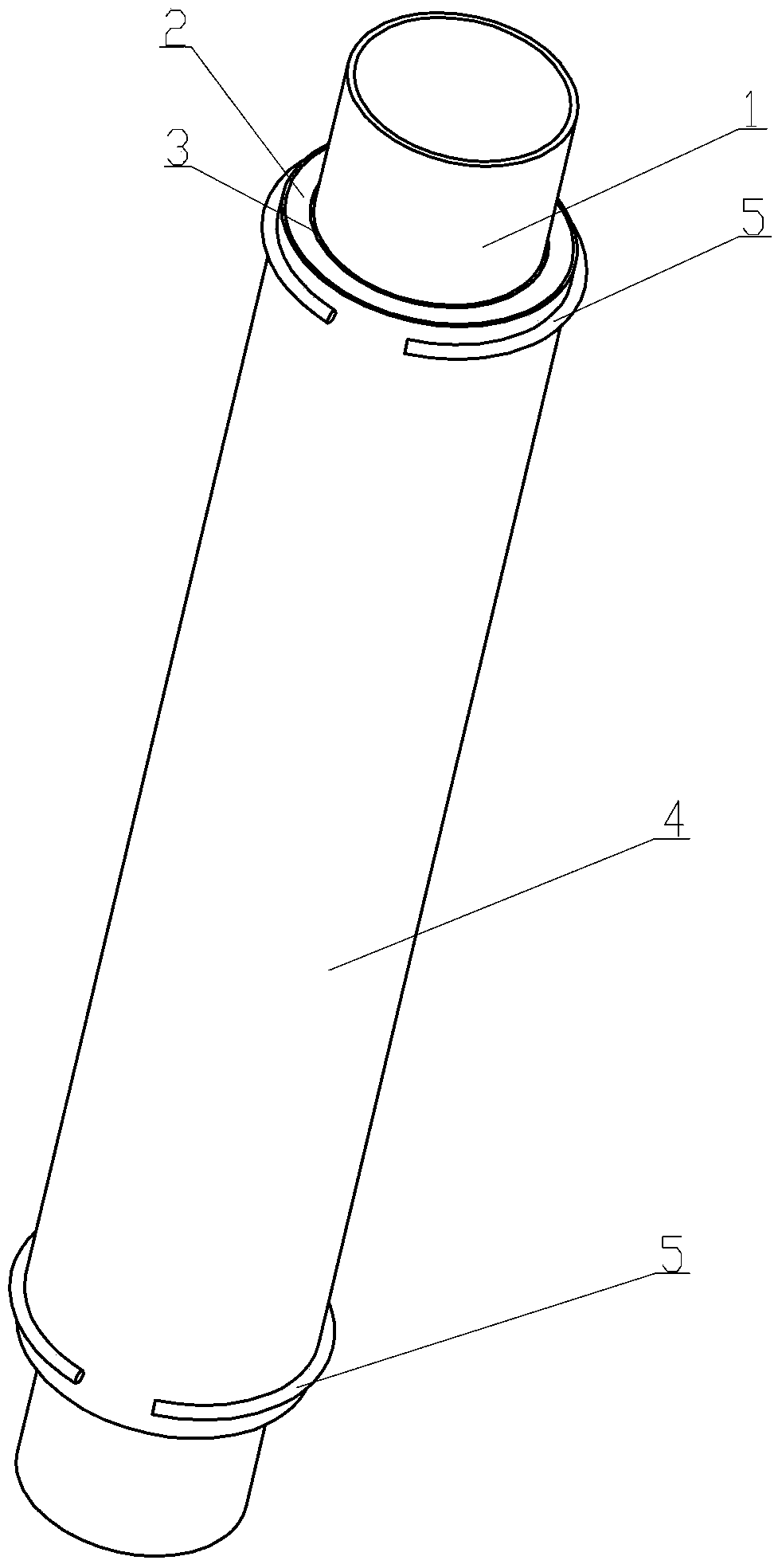

[0021] Example 1, such as Figure 1 to Figure 2 As shown, an electric heating tube for heating a liquid includes a metal tube 1, and the liquid to be heated flows through the metal tube 1. The metal tube 1 can be a stainless steel tube, an aluminum tube or a copper tube, or other metal tubes , the thickness of the tube wall is less than or equal to 2mm, which can ensure its heat transfer efficiency. The metal tube 1 is provided with an insulating layer 2, and the insulating layer 2 mainly plays an insulating role. It can be a ceramic tube, a quartz glass tube or a microcrystalline stone tube and the like, and the insulating layer 2 can be an insulator. It is a hollow cylindrical body set outside the metal pipe 1, so that the insulating layer 2 passing through the hollow cylindrical body is set on the metal pipe. There is a heat conduction layer 3 between the metal pipe 1 and the ceramic pipe 2. The heat conduction layer 3 is a heat conduction oil layer. The heat conduction oi...

Embodiment 2

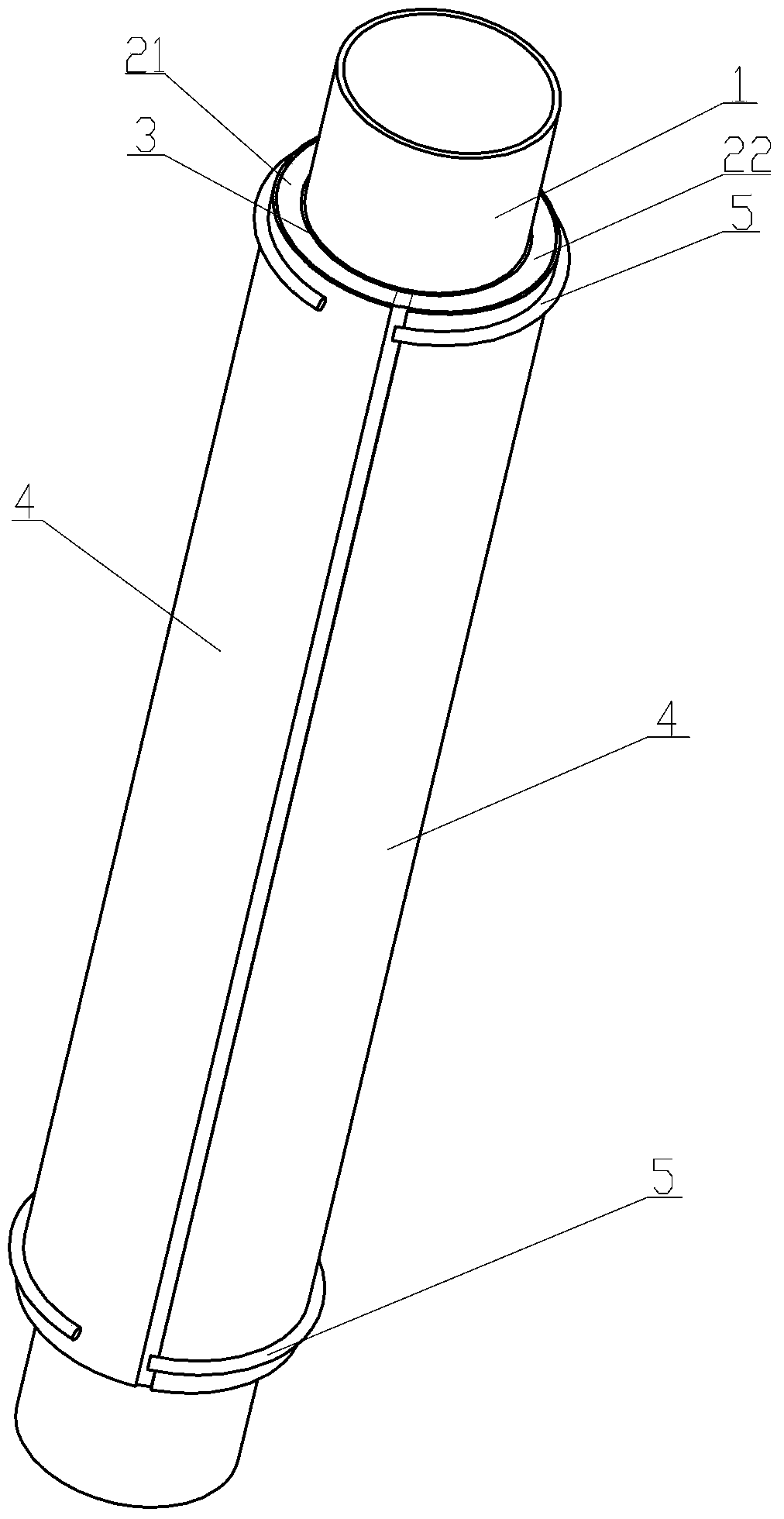

[0022] Example 2, such as Figures 3 to 4 As shown, the difference from Embodiment 1 is that the insulating layer 2 is different. Specifically, the insulating layer 2 is a sheet-like body that surrounds the outer wall of the metal tube 1, and can be one or more sheet-like bodies that surround the outer wall of the metal tube 1. , can use 2 pieces, 3 pieces, 4 pieces, 6 pieces, etc., the best implementation mode is to use two pieces, the metal pipe 1 can be a hollow circular pipe, and the two insulation layers 2 can be attached to the outer wall of the metal pipe 1 The left arc-shaped piece 21 and the right arc-shaped piece 22 , the left arc-shaped piece 21 and the right arc-shaped piece 22 basically wrap the outer wall of the metal pipe 1 . The insulating layer 2 is composed of two semi-arc-shaped sheets, mainly for the purpose of effectively contacting the outer wall of the metal pipe 1 in different thermal expansion and contraction ranges to improve thermal efficiency, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com