Technology of injection moulding with surface of glass bottle body fully coated with plastic and mould thereof

A molding process and technology of glass bottles, applied in the direction of coating, etc., can solve the problems of glass bottles being fragile, product quality cannot be guaranteed, and it is difficult to achieve full coating, etc., to achieve good appearance, good appearance and soft feeling, and ensure production safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

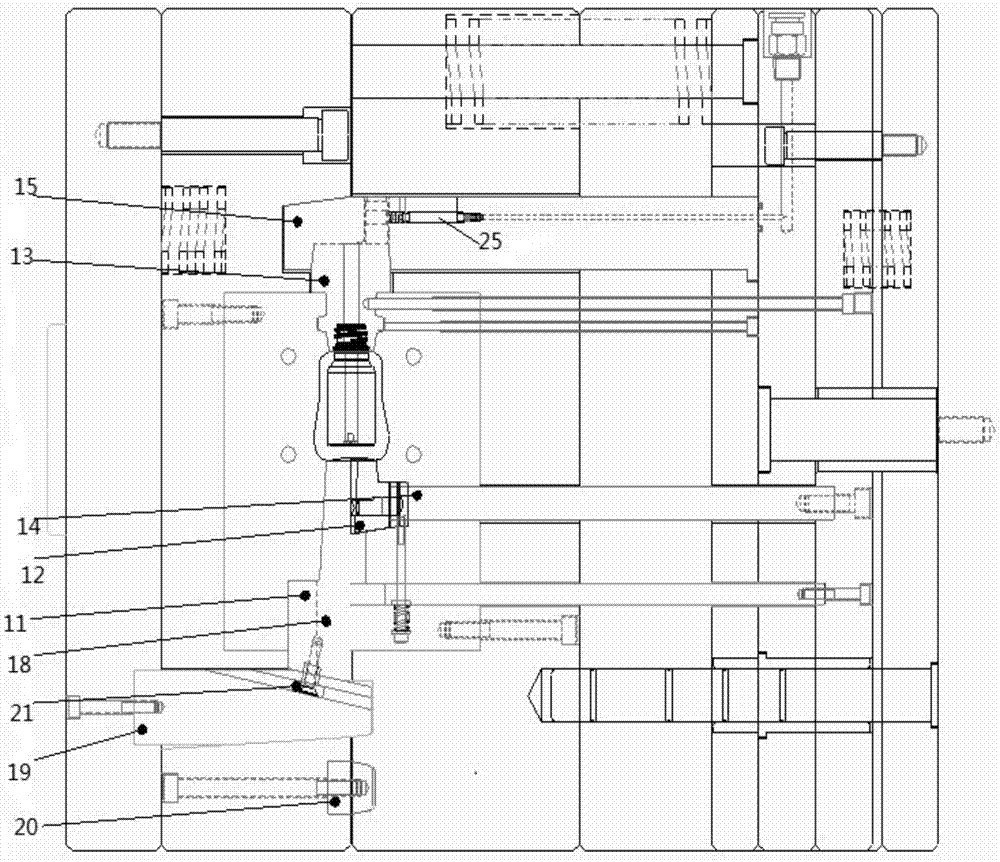

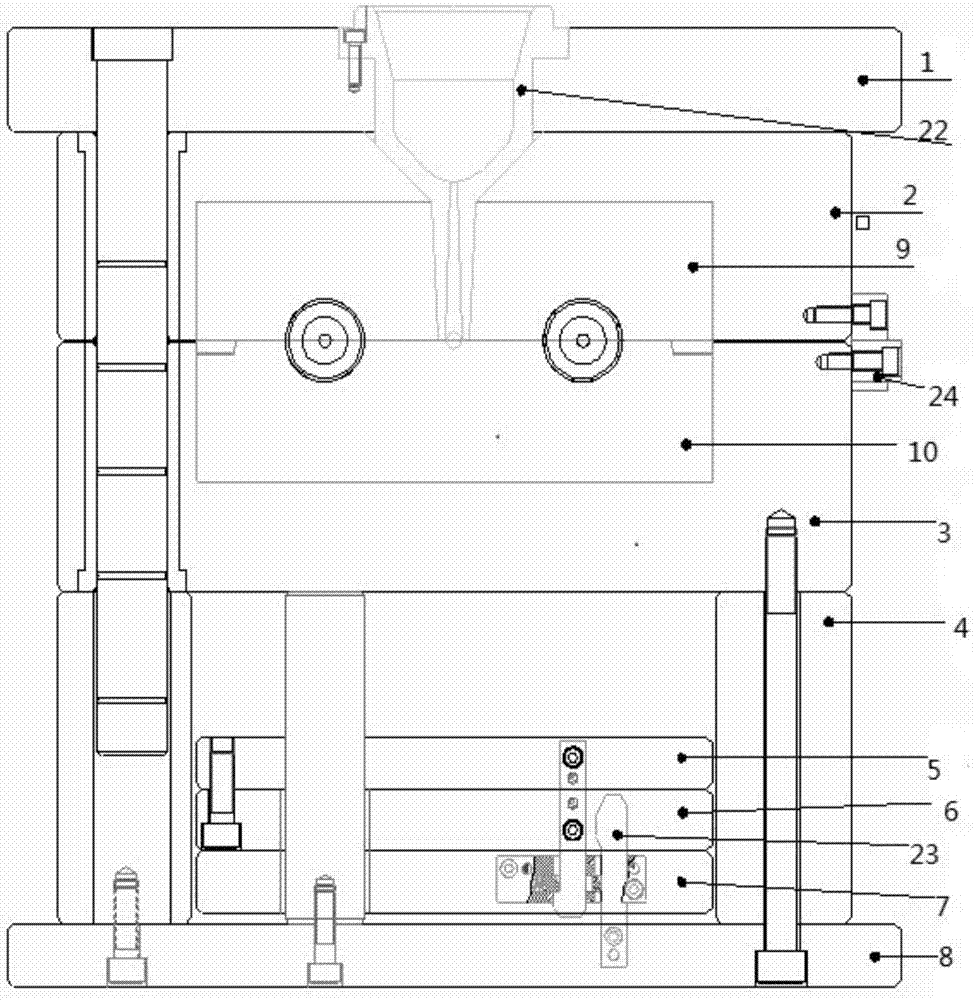

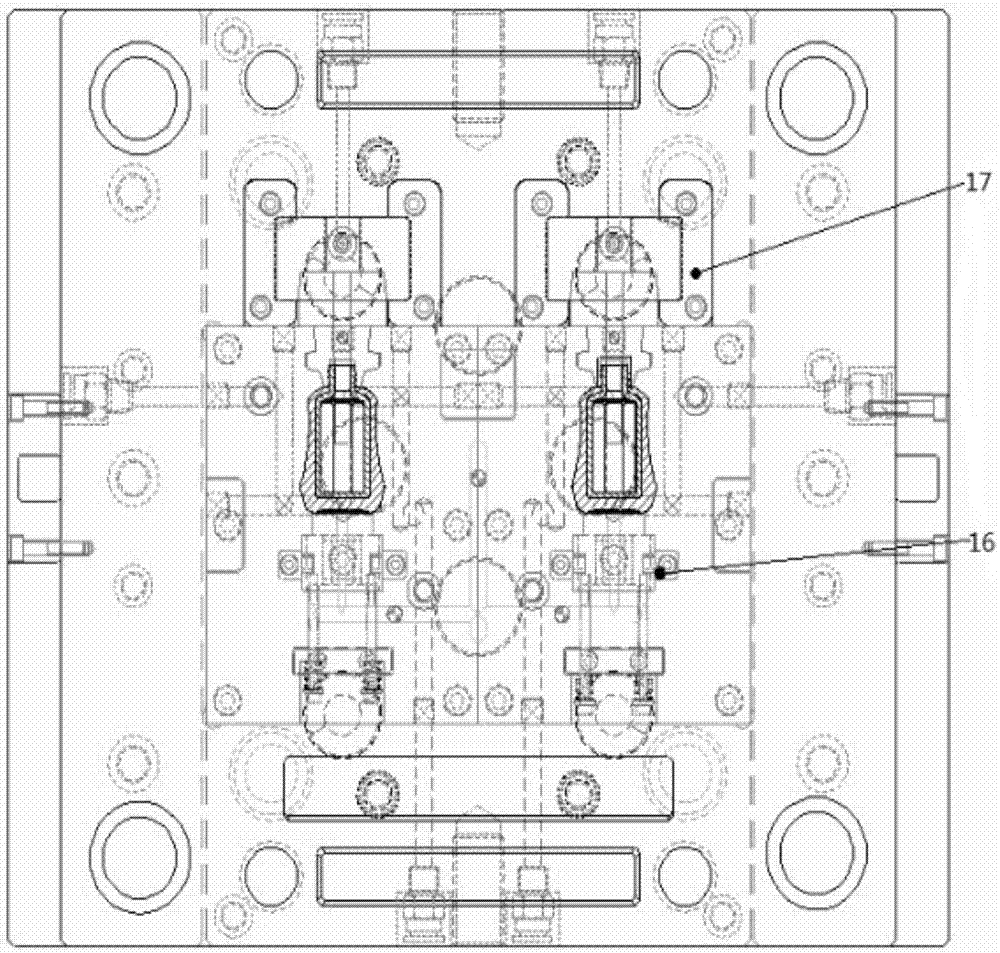

[0028] This embodiment 1: The injection molding process of the glass bottle body surface fully covered with plastic provided in this embodiment, see Figure 4 , including the following steps:

[0029] S1: Prepare equipment and raw materials: Prepare molds and injection molding machines that match the molds, and prepare plastic raw materials and glass bottles.

[0030] S2: Install and adjust the position of the mold, then place the glass bottle between the front and rear mold inserts of the mold, and then use a plastic sleeve to fit the glass bottle, that is, the tooth position of the glass bottle, to fix it, and then put it into the mold core of the mold And the mold cavity to ensure that the glass bottle is balanced with the core of the mold to avoid the glass bottle from bursting; in addition, the quality of the glass bottle should be checked before placing the glass bottle, and the texture of the bottle body needs to be checked for cracks. The glass is highly polished.

...

Embodiment 2

[0038] Example 2: The injection molding process of the glass bottle body surface fully covered with plastic provided in this example is basically the same as Example 1, the difference is that the injection molding process parameters include: setting the temperature of the front barrel to 265°C , The temperature of the middle barrel is 250°C, the temperature of the rear barrel is 210°C; the temperature of the nozzle is set to 240°C; the temperature of the mold is set to 90°C; the injection pressure is set to 80Mpa; the screw speed is set to 3600r / min; set the injection molding time to 50s, the holding time to 5s, and the cooling time to 20s. Others are the same as in Example 1.

Embodiment 3

[0039] Example 3: The injection molding process of the glass bottle body surface fully covered with plastic provided in this example is basically the same as Example 1, the difference is that the injection molding process parameters include: setting the temperature of the front barrel to 285°C , The temperature of the middle barrel is 280°C, the temperature of the rear barrel is 240°C; the temperature of the nozzle is set to 250°C; the temperature of the mold is set to 110°C; the injection pressure is set to 130Mpa; the screw speed is set to 3000r / min; set the injection molding time to 90s, the holding time to 0s, and the cooling time to 90s. Others are identical with embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com