Equipment for calcinating cement clinker in large granule and fluidiazation

A calcination device and fluidization technology, applied in the field of large particle fluidized cement clinker calcination device, can solve the problems of unstable calcination thermal system, poor quality of cement clinker, uneven ventilation of moving bed shaft kiln, etc. Achieve the effect of small fluctuation, not easy to burst, and prolong the residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

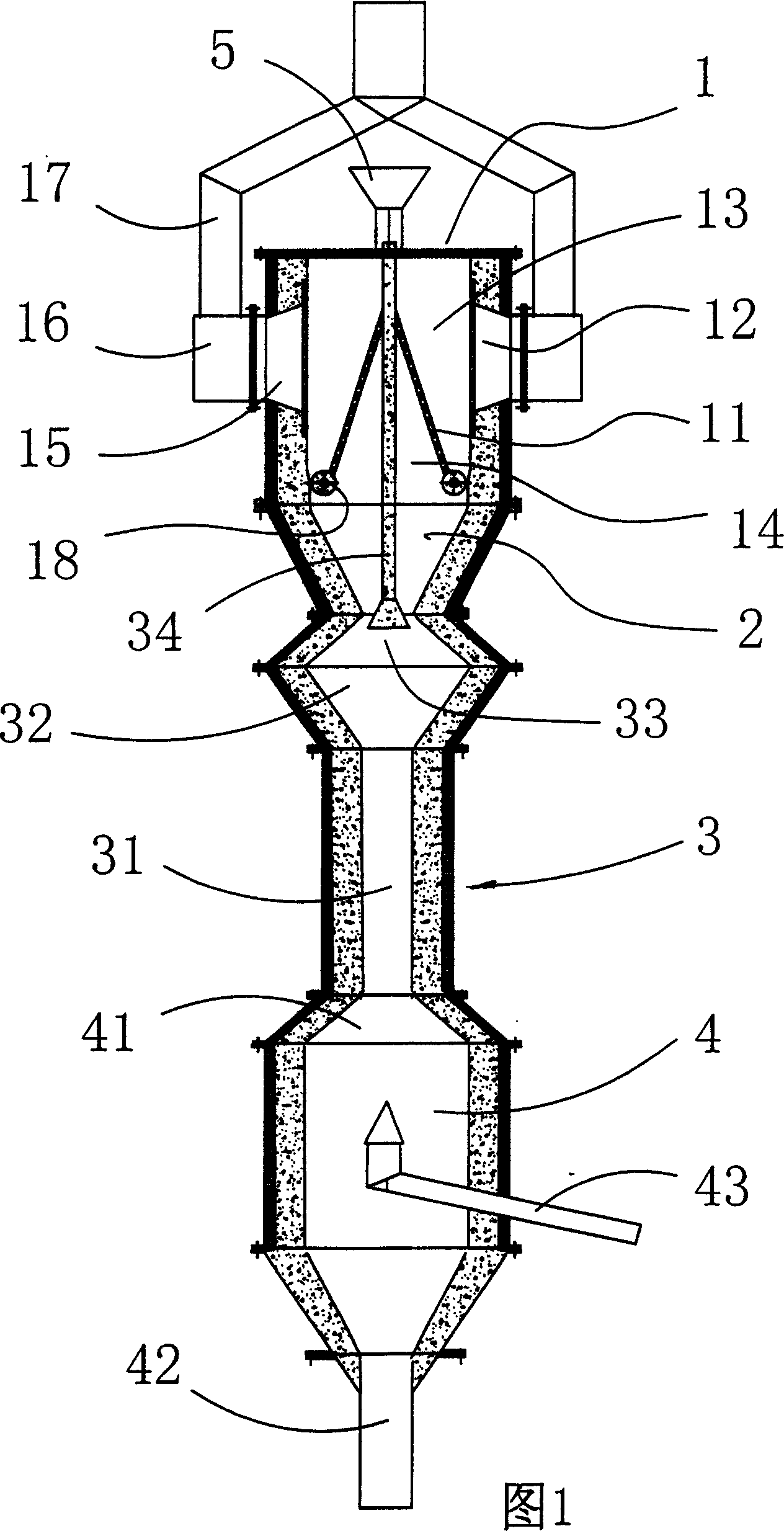

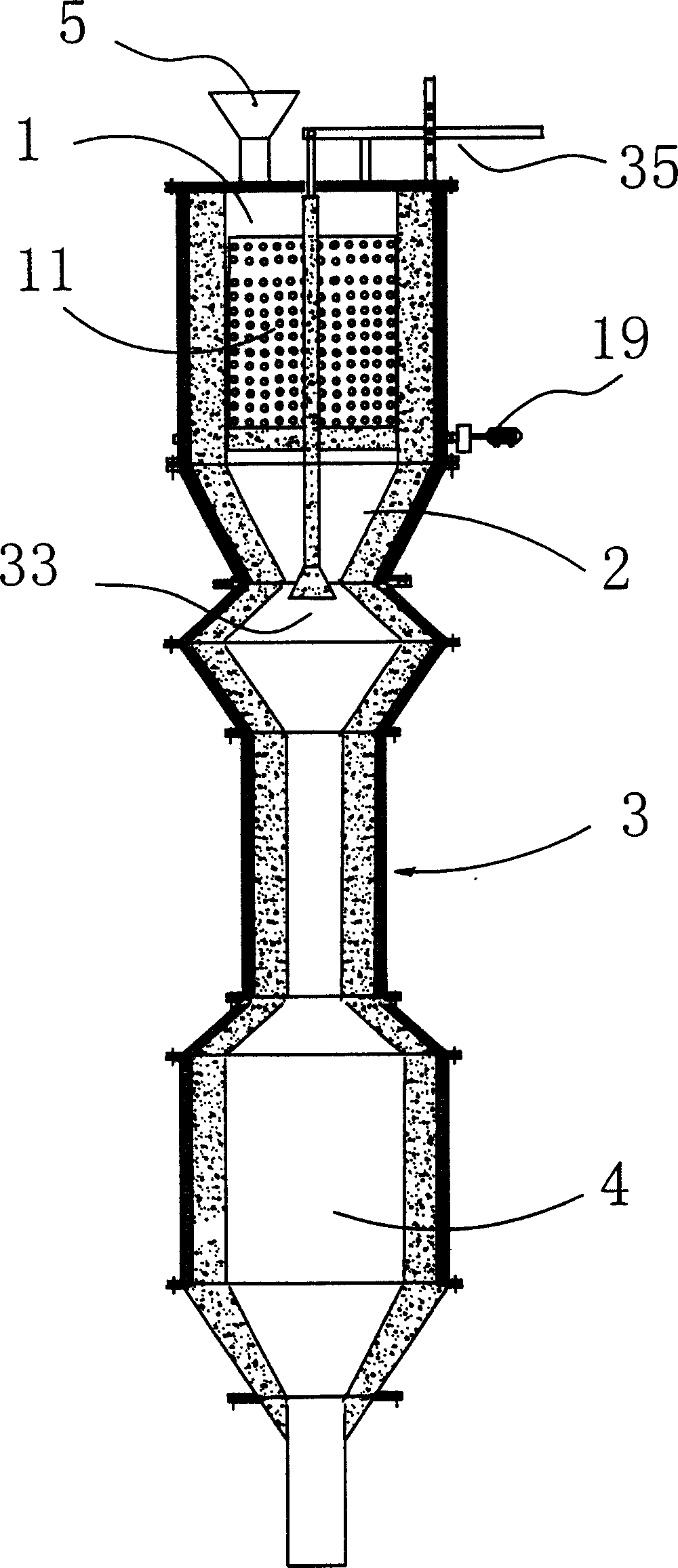

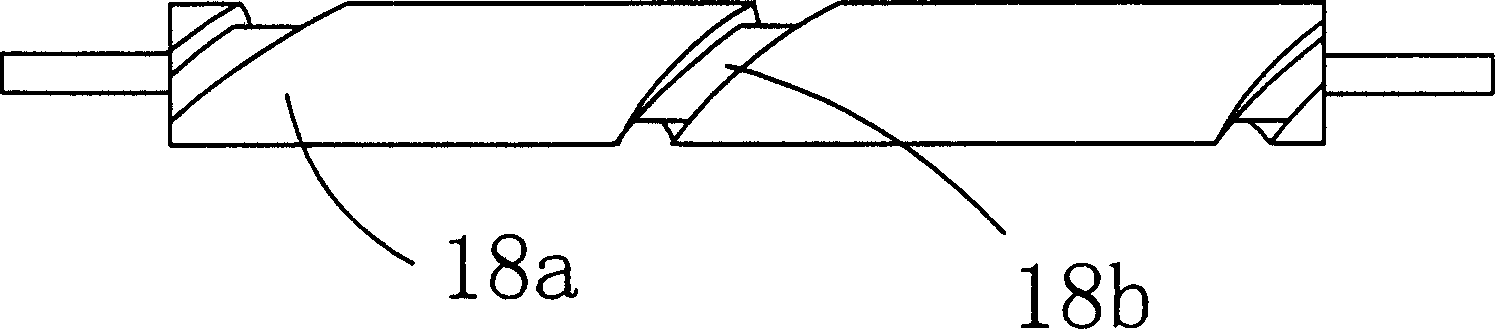

[0019] Figure 1, figure 2 and image 3 As shown: the preheating chamber 1 is in the shape of a square cylinder, with two inner grate plates 11 and two outer grate plates 12, the outer grate plates 12 are placed vertically, and the inner grate plates 11 are placed obliquely, forming two symmetrical spaces for storing materials 13, and a ventilation space 14 with a triangular cross-section is formed between the two inner grate plates 11, and the smoke outlet 15 is arranged on the side of the outer grate plate 12. Inside and outside grate plate 11,12 can be circular hole type grate plate, also can be slotted grate plate (fence shape grate plate), what this example adopted is the circular hole type grate plate. The hot gas coming up from the fluidized pre-calcination chamber 2 enters the ventilation space 14, then passes through the inner and outer grate plates 11, 12 and materials transversely, and is discharged through the smoke outlet 15, the ash collecting hopper 16 and the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com