Demoulding structure for plastic helical gear injection molding

An injection molding, helical gear technology, applied in the direction of gears, other household appliances, household appliances, etc., can solve the problems of helical gear helical shape deformation, gear cavity cracks, longer injection molding cycle, etc., and shorten the molding cycle. , the mold structure is compact, the effect of ensuring the strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

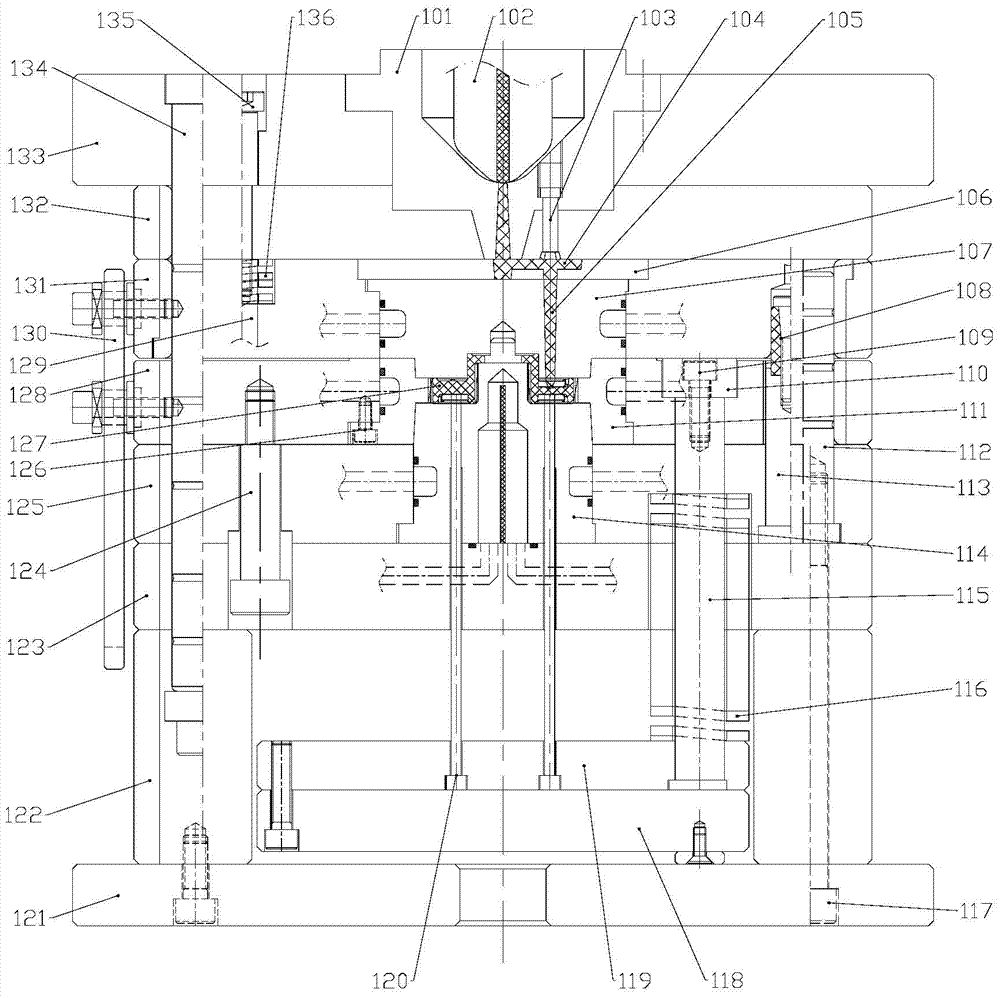

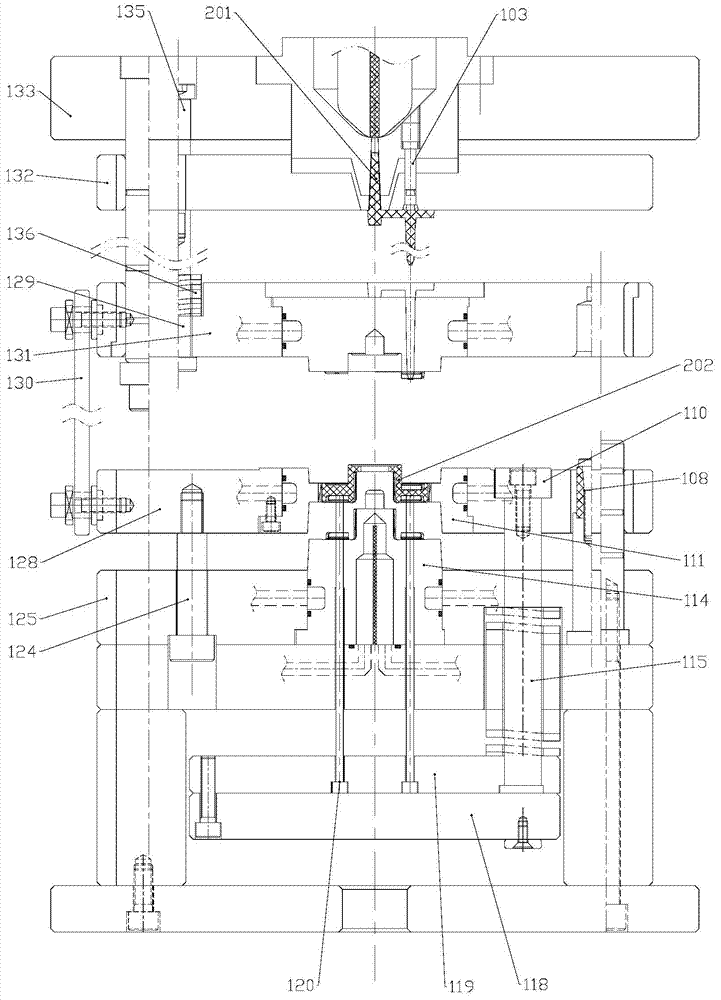

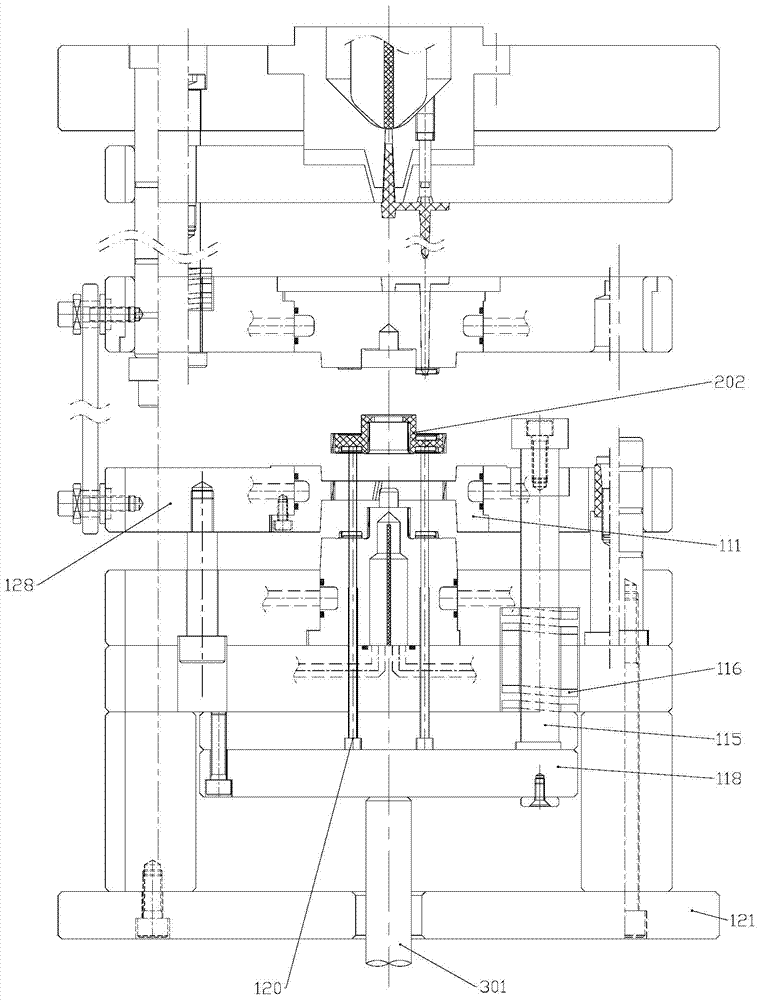

[0016] The present invention will be further elaborated below in conjunction with the accompanying drawings: the plastic helical gear mold includes a fixed mold part and a movable mold part.

[0017] like figure 1 As shown, the top plate 133 of the fixed mold part, the stripper plate 132 and the fixed mold cavity plate 131 are fixedly connected by the guide post 134 fixed on the top plate. The stripping plate 132 and the fixed mold cavity plate 131 can move under the guidance of the guide column 134, and the moving distance is limited by the stop screw 135 and the screw pull rod 129 arranged on the fixed mold part. Closed on the spring 136 on the screw pull rod 129 and the nylon rubber plug 108 control that is located on the fixed mold cavity plate 131, the spring 136 is contained between the stripping plate 132 and the fixed mold cavity plate 131 and is sleeved on the screw pull rod 129. The fixed mold cavity 107 is arranged on the fixed mold cavity plate 131 and is fixed on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com