Patents

Literature

61results about How to "Uniform opening" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

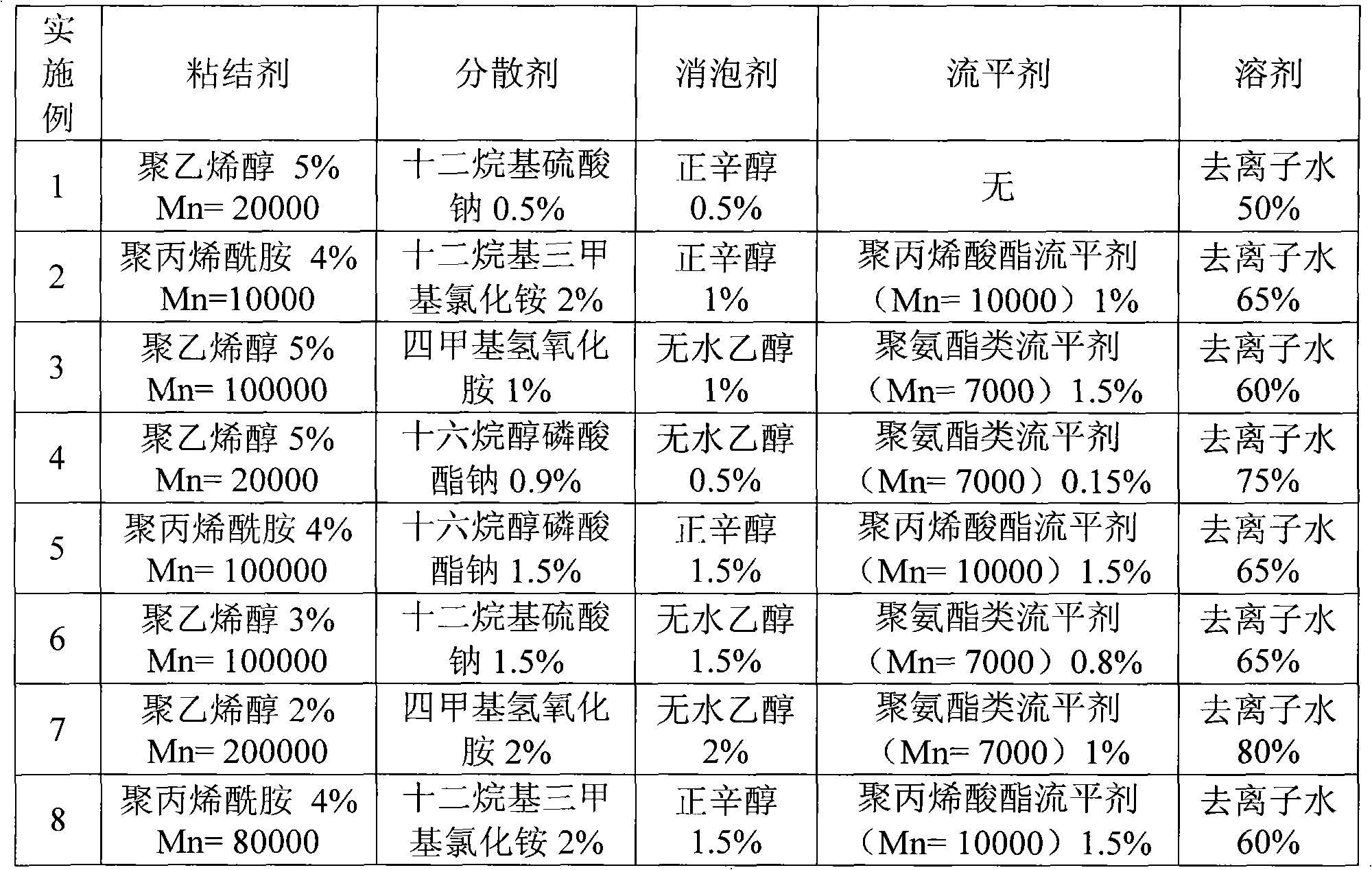

Mask electro-forming method for vaporization coating of organic light-emitting display

ActiveCN1804138AUniform openingEasy transferVacuum evaporation coatingPhotomechanical apparatusPosition toleranceDisplay device

The mask electroforming method for OLED comprises: preparing module core, pre-treating the core; sticking mask; exposing; developing; deoiling; cleaning in water; activating / passivating; cleaning; electroforming mask; cleaning; removing mask; peeling mask; bonding with silk screen; detecting the product; packing. This invention can prepare the high-precise mask for OLED with thickness less than 0.5mm, and has opening tolerance up to í‚0.005mm; for example, for a 370mmí‡470mm mask plate, the crosshole position tolerance just is í‚0.008mm.

Owner:KUN SHAN POWER STENCIL

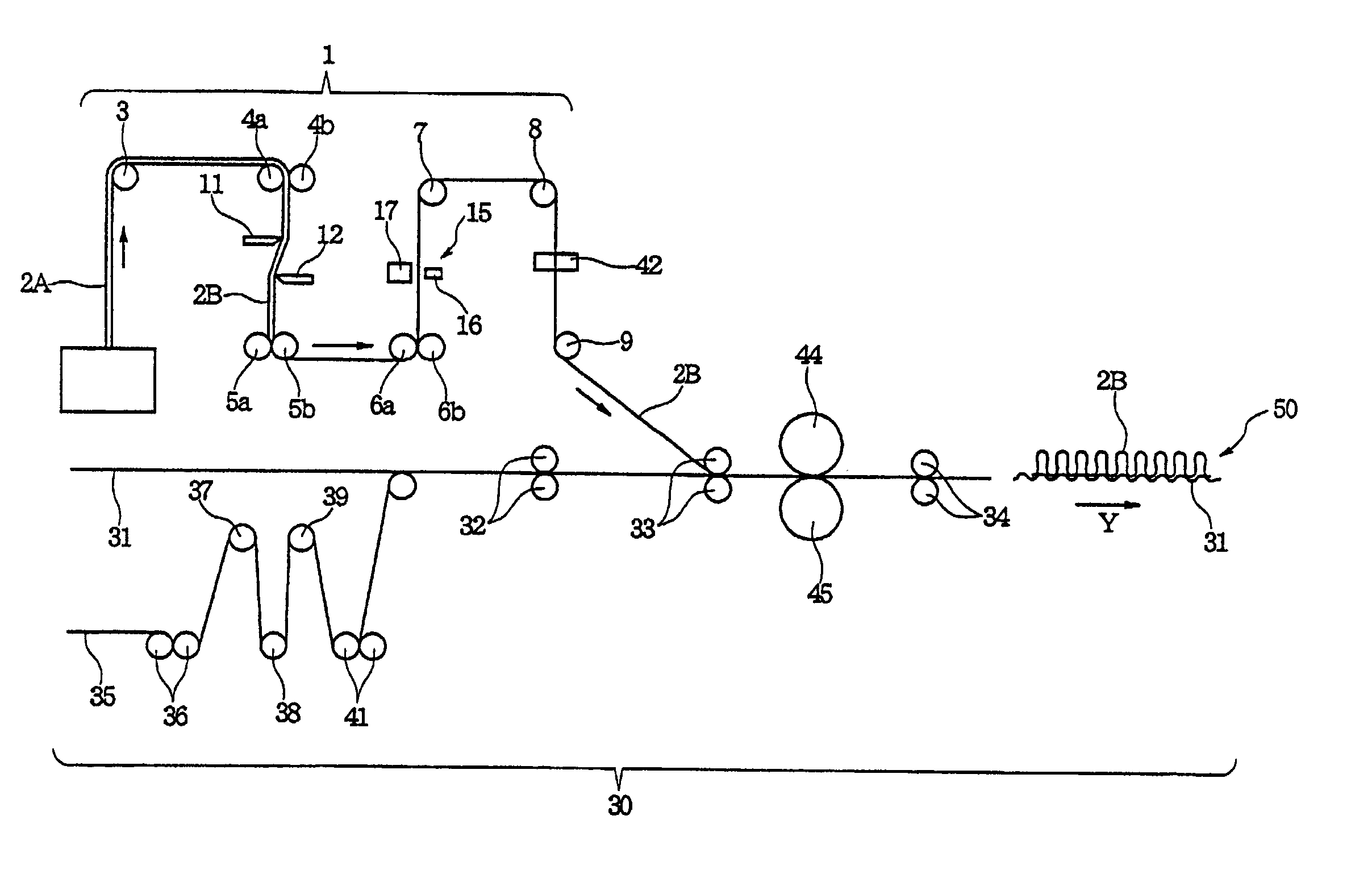

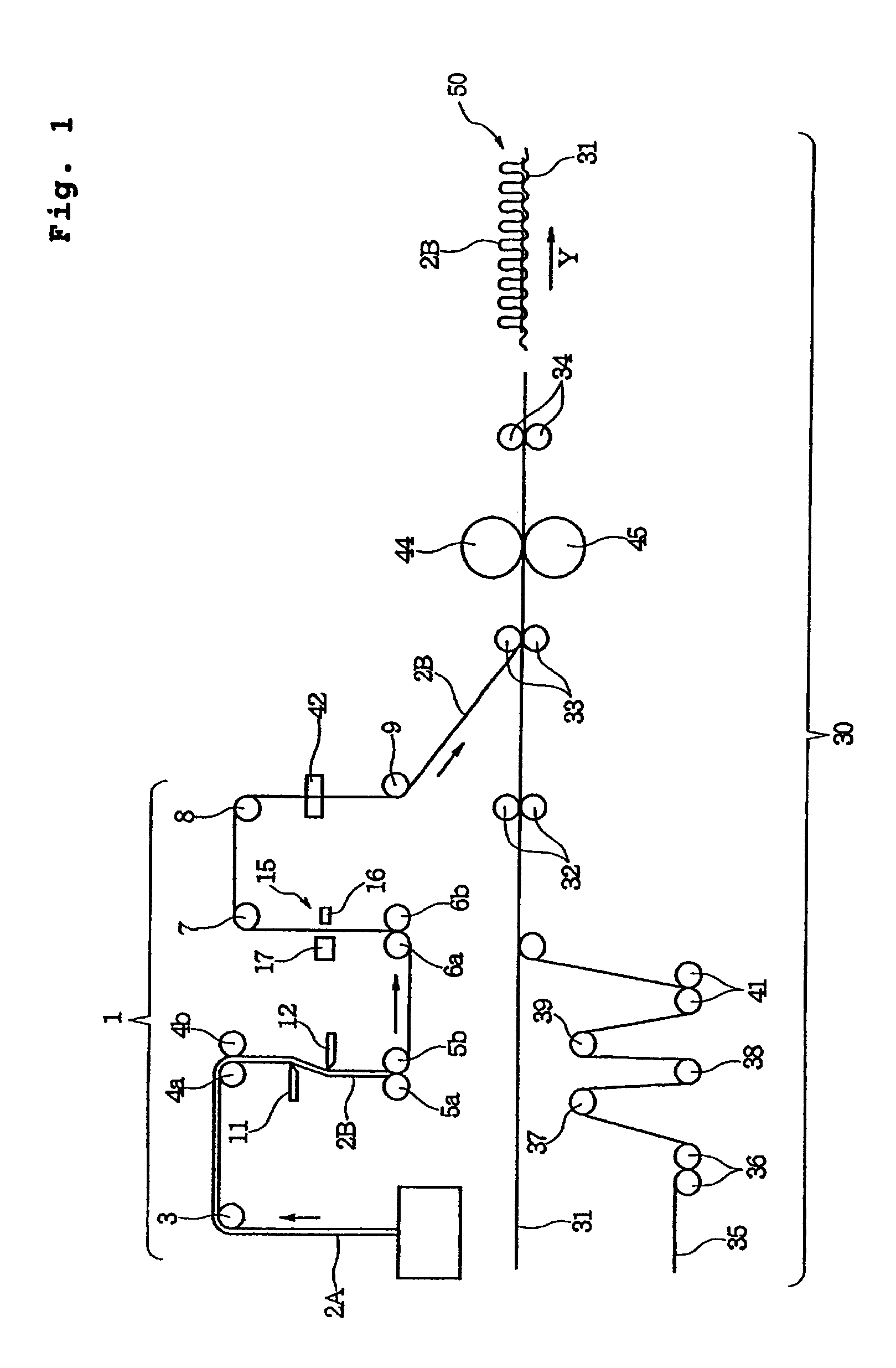

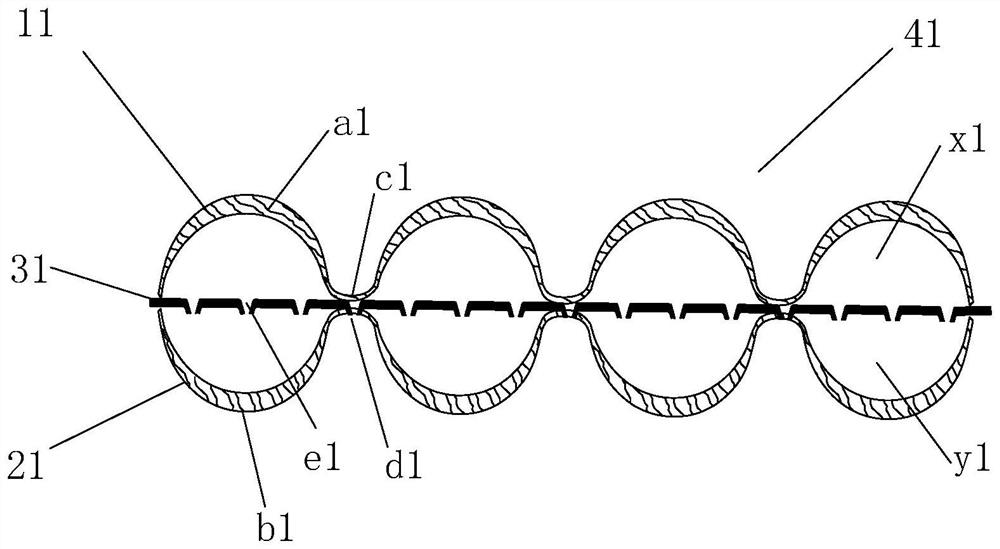

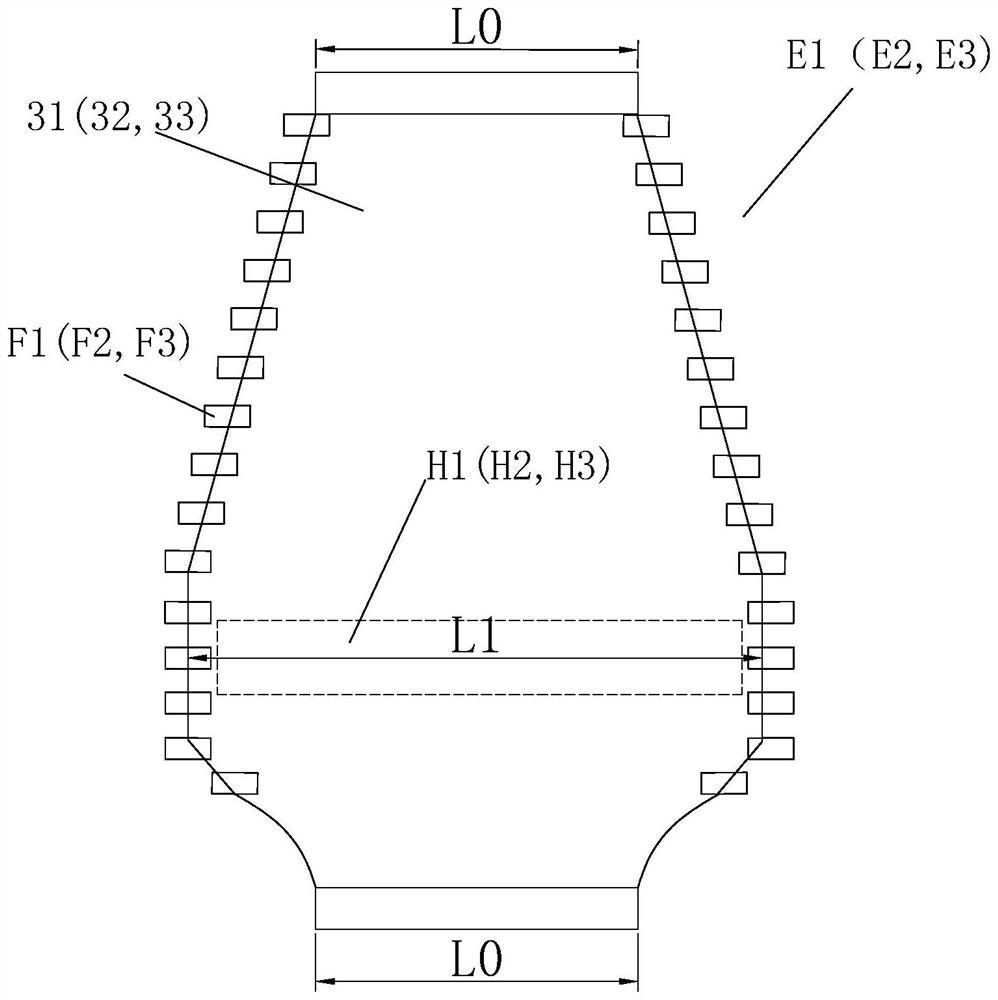

Method and apparatus for opening continuous filaments

InactiveUS7003856B2Simple conditionsUniform openingFilament manufactureFibre cleaning/openingEngineeringMechanical engineering

A method and an apparatus for opening continuous filaments provide stable quality of fibrous layer after opening crimped TOW. The TOW is transported by means of a plurality of rolls. While transported, the TOW is applied a resistance on one side of the TOW by slidingly contacting a sliding body onto the TOW at between rolls. As a result, continuous filaments stacked in a thickness direction of the TOW are caused to sift in a transporting direction of the TOW. Thus, the TOW is opened and the continuous filaments are spread in a width direction of the TOW.

Owner:UNI CHARM CORP

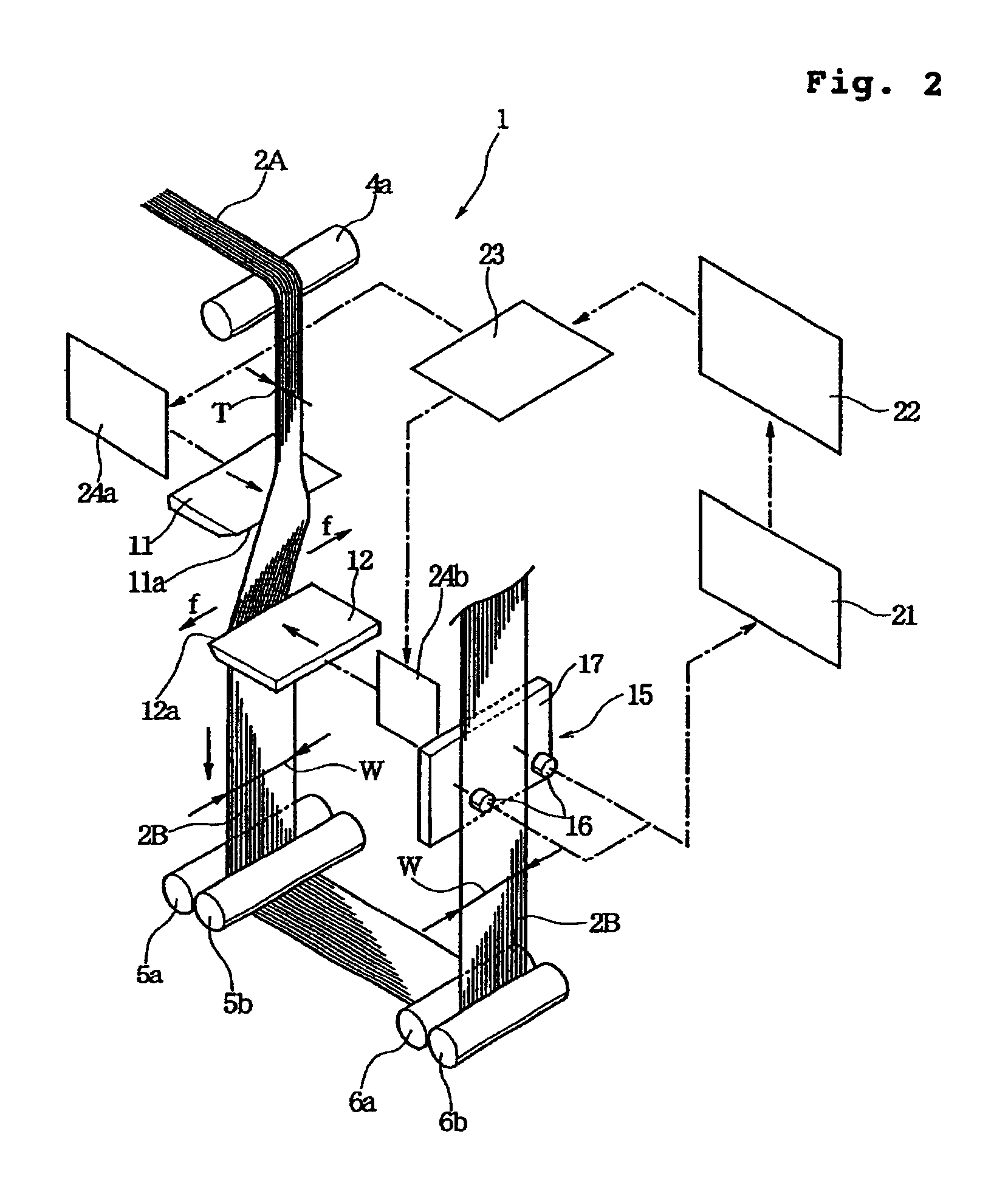

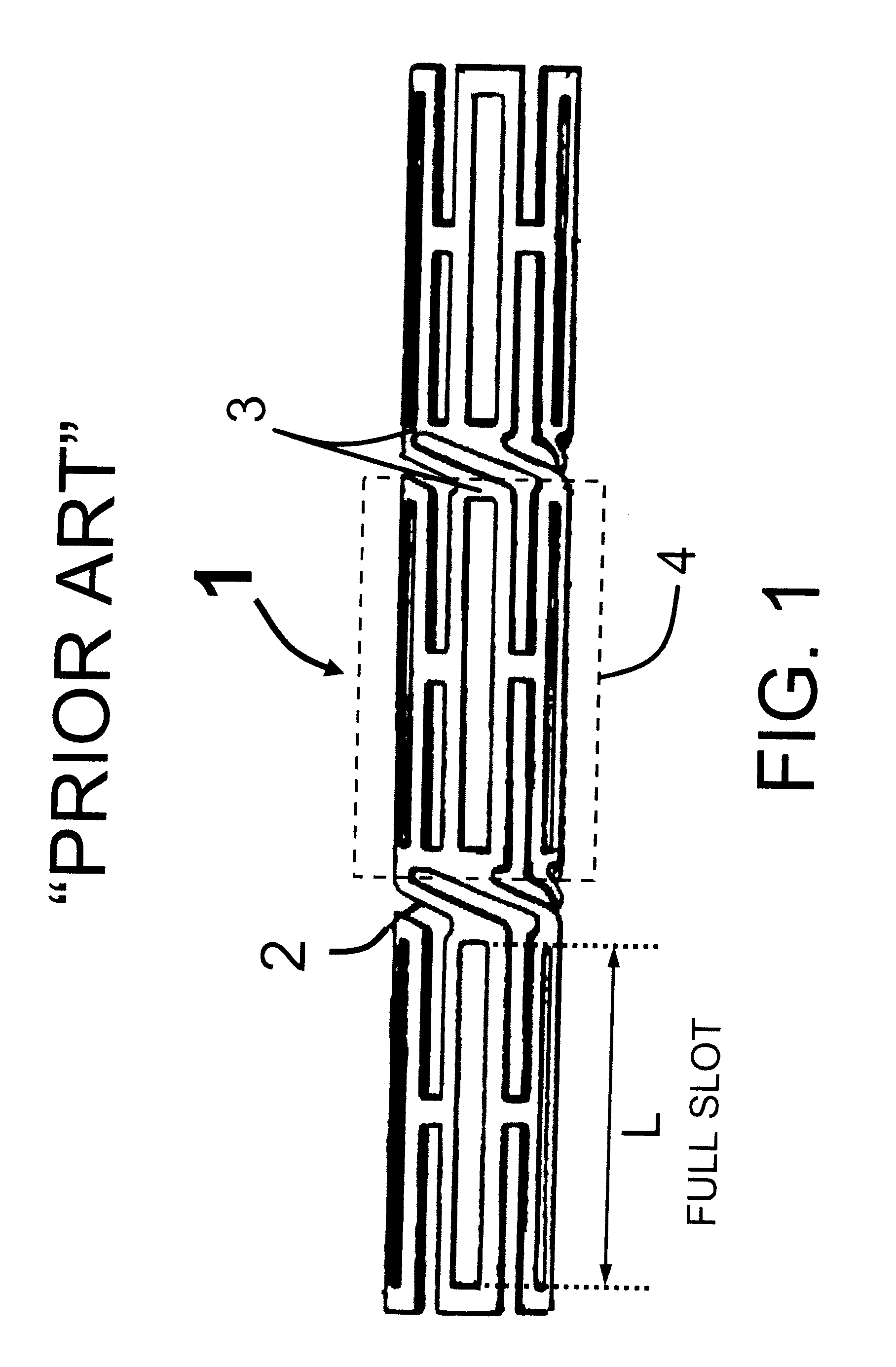

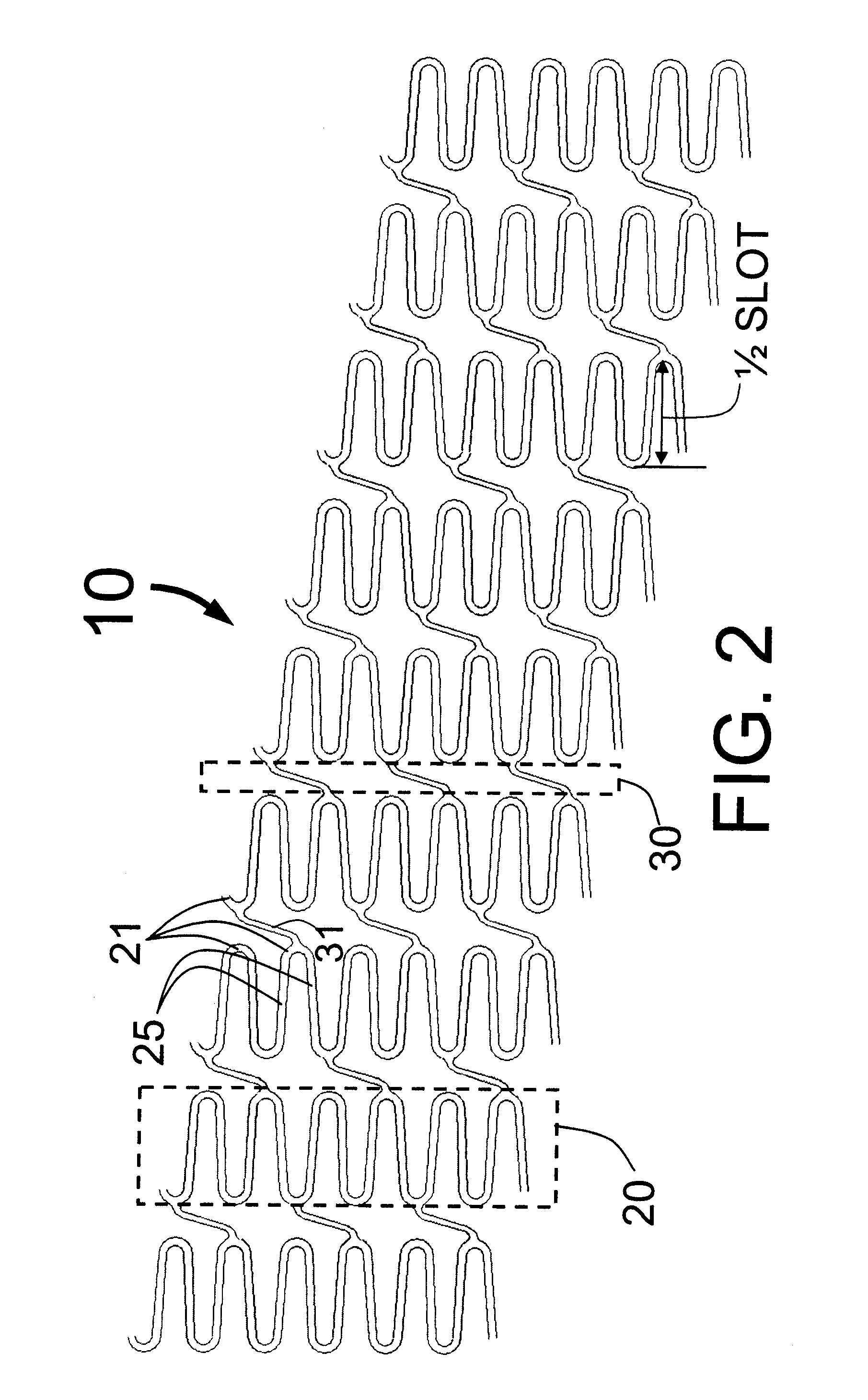

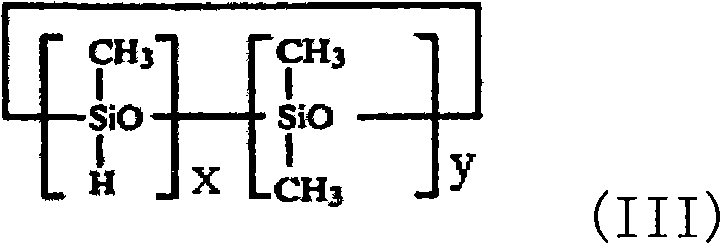

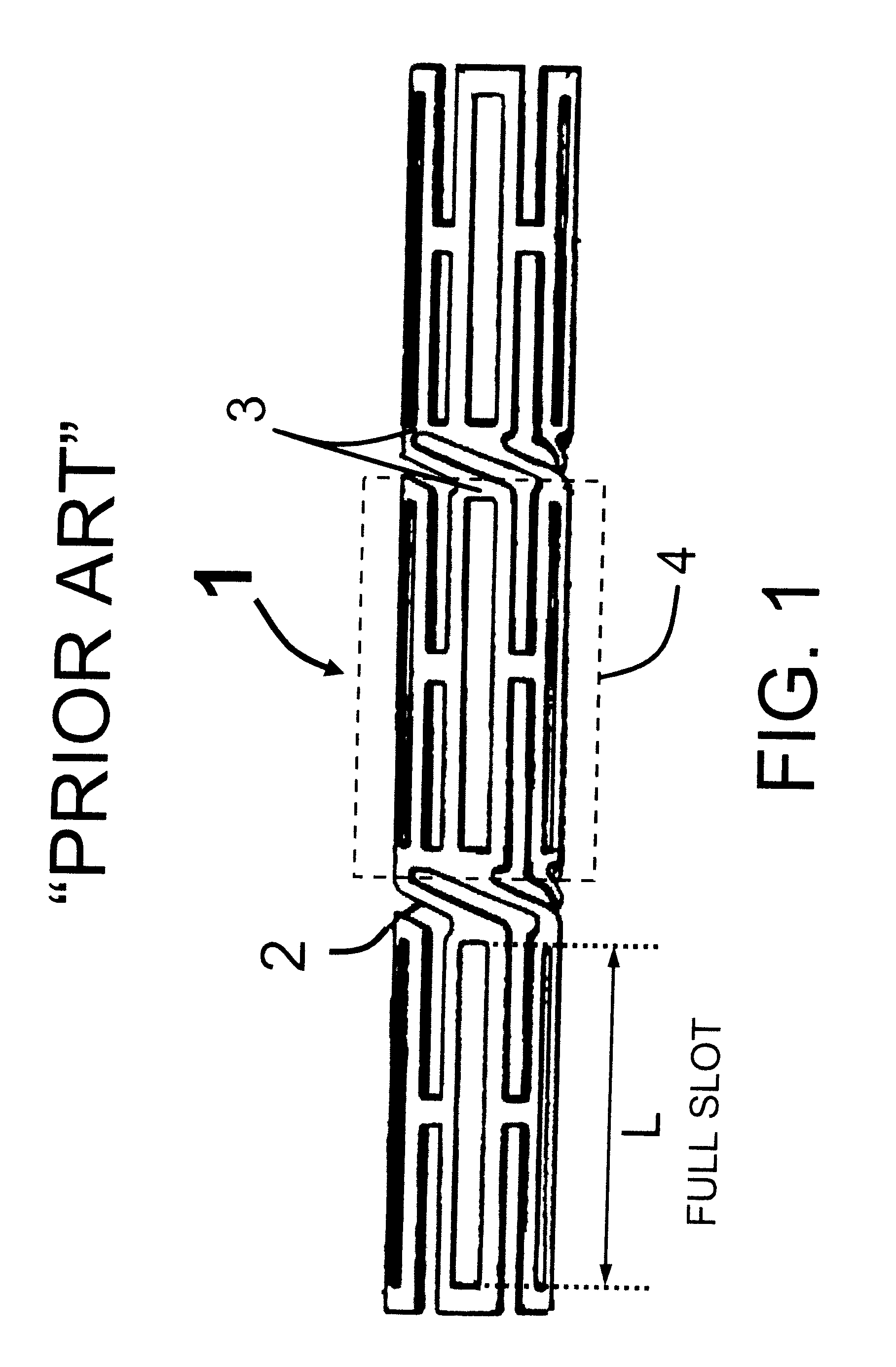

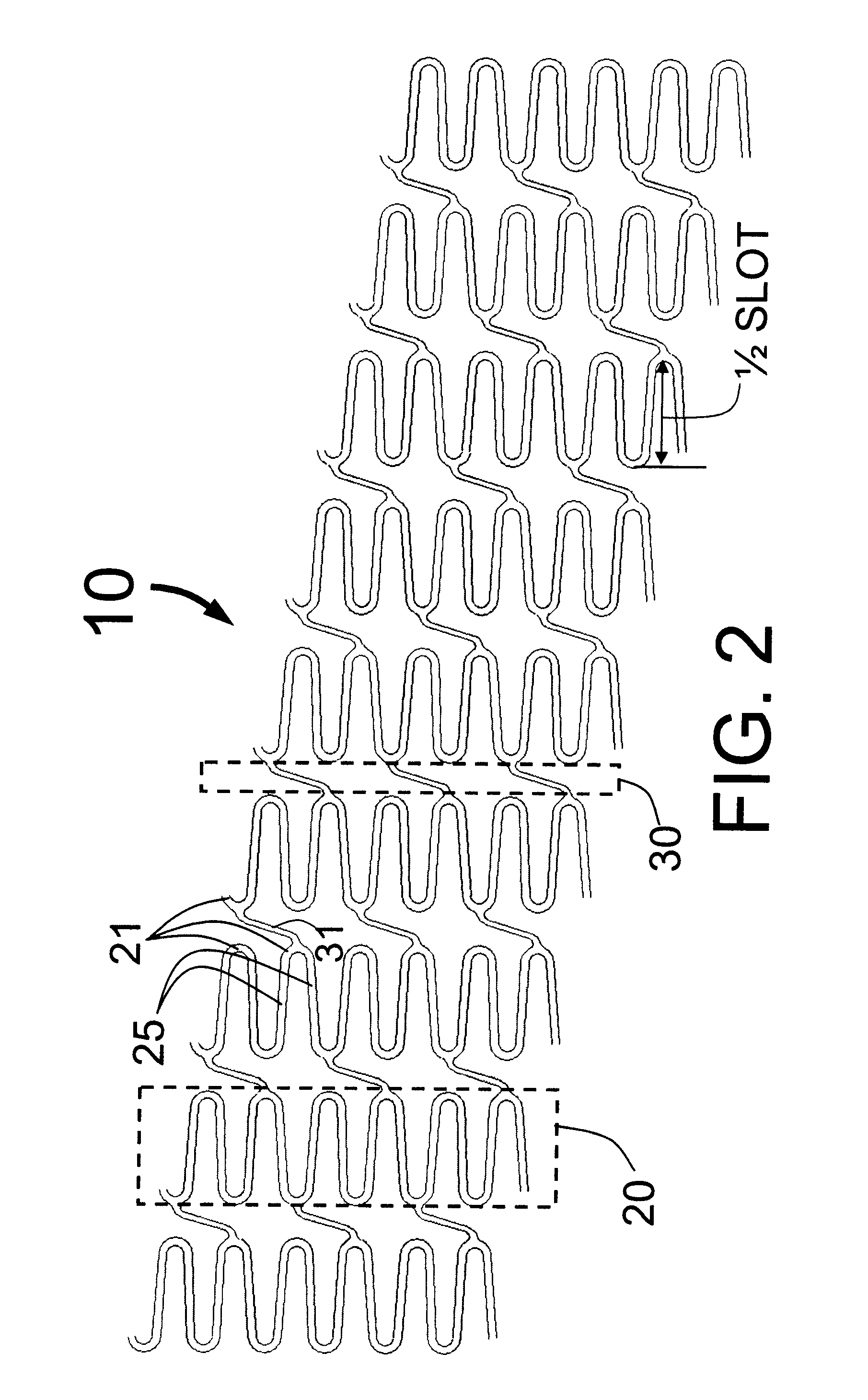

Hybrid stent with helical connectors

ActiveUS20110093059A1Minimal fish scalingIncrease flexibilityStentsBlood vesselsInsertion stentMaximum diameter

The present invention is a hybrid stent design using half-slot circumferential sets of strut members with short (<1.5 mm) slot length that has minimal fish scaling and excellent stent retention and flexibility. These half-slot circumferential sets of strut members are connected one to the other with helical connectors similar to those of the Palmaz stent. One important difference in the design of the stent of the present invention is that the helical connectors are attached to every other crown (rather than connected to every crown) to further improve stent flexibility. By appropriately varying the strut width of both the connected and unconnected curved crowns to be greater at the center than at their ends, an increased radial strength can be provided for a given maximum strain that is imparted to the stent when it is expanded to its maximum diameter.

Owner:SVELTE MEDICAL SYST

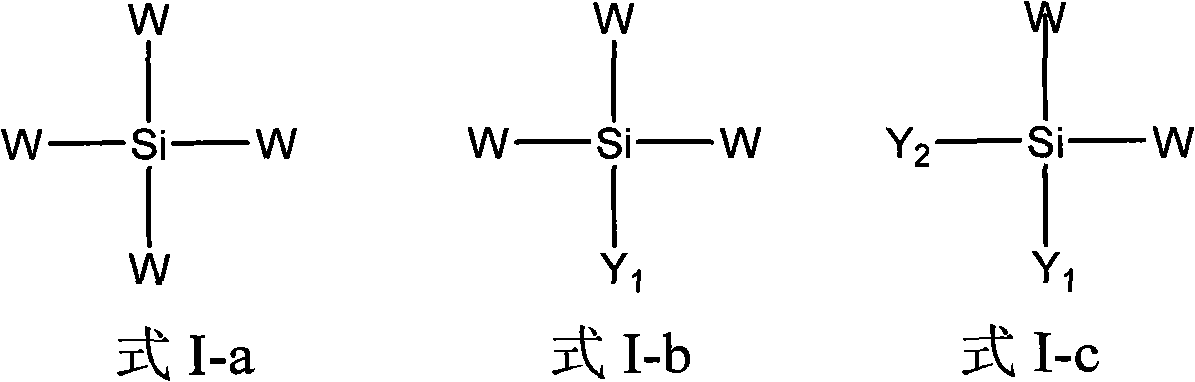

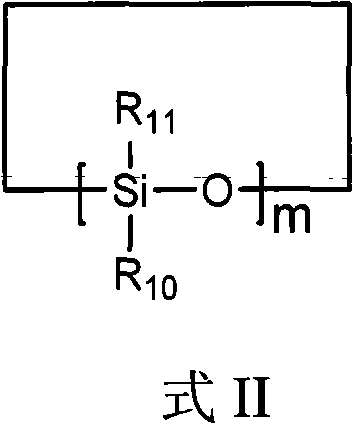

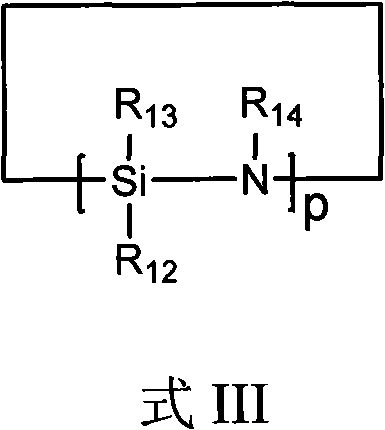

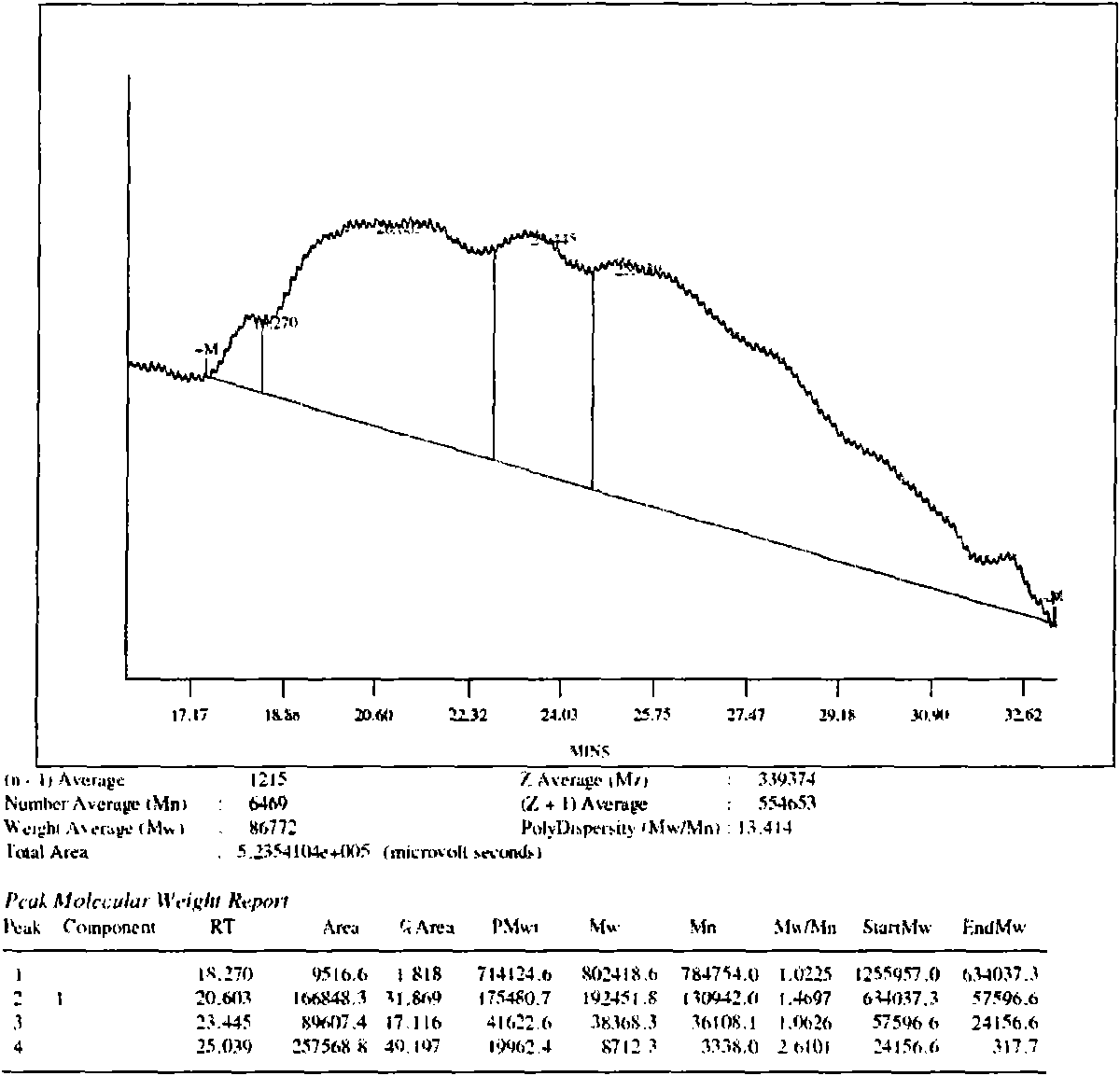

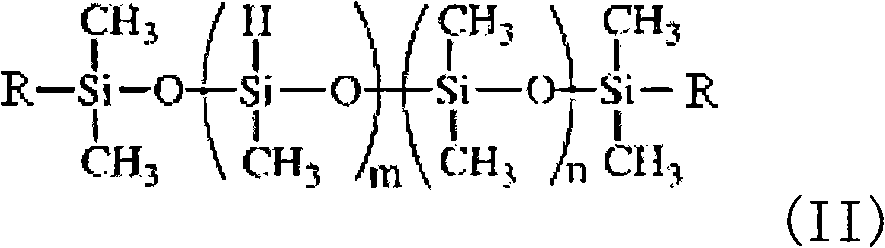

Mold release agent and preparation method and application thereof

The invention provides a mold release agent, which contains the following components: a silicon-hydrogen bond-containing polysiloxane compound, a cross-linking agent, a catalyst and a solvent, wherein the cross-linking agent is a silicon compound containing Si-OH groups and / or a silicon compound which can form the Si-OH groups through hydrolyzation. The mold release agent is a semi-permanent mold release agent, and has the advantages of rapid low-temperature solidification, less mold release agent transfer, less wax deposition, convenient construction, low cost and the like; the produced product has uniform openings; and the mold release agent particularly achieves major breakthrough in the field of producing polyurethane foam products. The invention also provides a method for preparing the mold release agent, and application of the mold release agent in producing polyurethane foam products, epoxy resin products, glass fiber reinforced epoxy resin products, rubber products, unsaturated polyester products and other polyurethane products.

Owner:HENKEL CORP

Complex Tang-dynasty jun glaze with blue spots in white and process for preparing jun porcelain by use of complex Tang-dynasty jun glaze

The invention discloses a complex tang-dynasty jun glaze with blue spots in white and a process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze. The process comprises: firstly crushing and molding carcass raw materials, and firing the carcass raw materials into plain carcass; then, immersing the plain carcass into slurry of glaze in white for glazing; applying slurry of the glaze with blue spots in surface points of the plain carcass after the slurry of the glaze in white adhered on the surface of the plain carcass is dried in air; and putting the plain carcass into a kiln for firing after the slurry of the glaze with blue spots is dried, thereby obtaining the complex Tang-dynasty jun glaze with blue spots in white. According to the Tang-dynasty jun glaze with blue spots in white and the process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze disclosed by the invention, milky white glaze is presented in the process of firing by adding zircon into a formula of the glaze in white; and the position of the glaze with blue spots is fixed by use of a secondary glazing mode. A coloring process of overglaze color or underglaze color adopted by general piebald porcelains is broken through; economic value of the jun porcelain is increased through innovation in glazing color and coating; and the jun porcelain, which is a Chinese characteristic, also represents advanced level of the production process in China, thereby increasing the social value of the jun porcelain.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

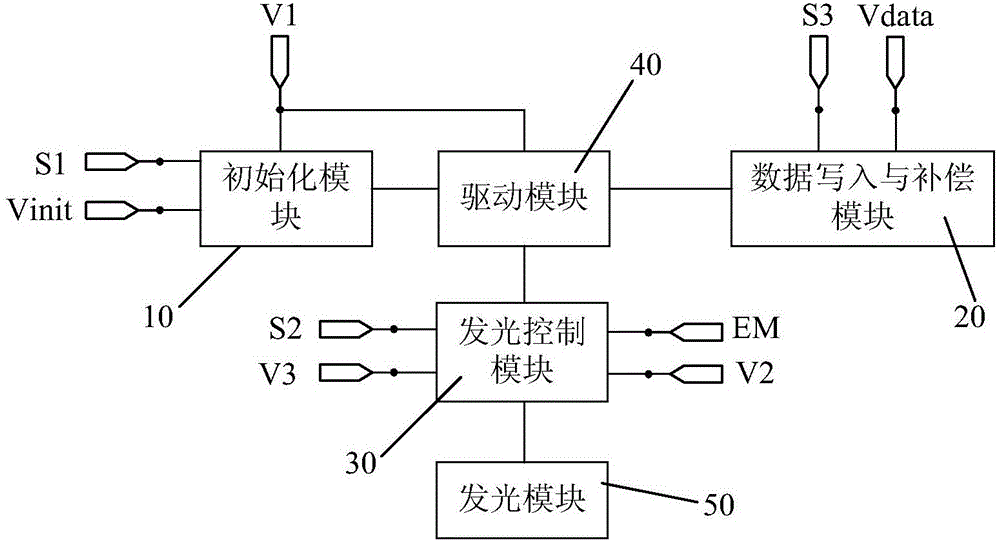

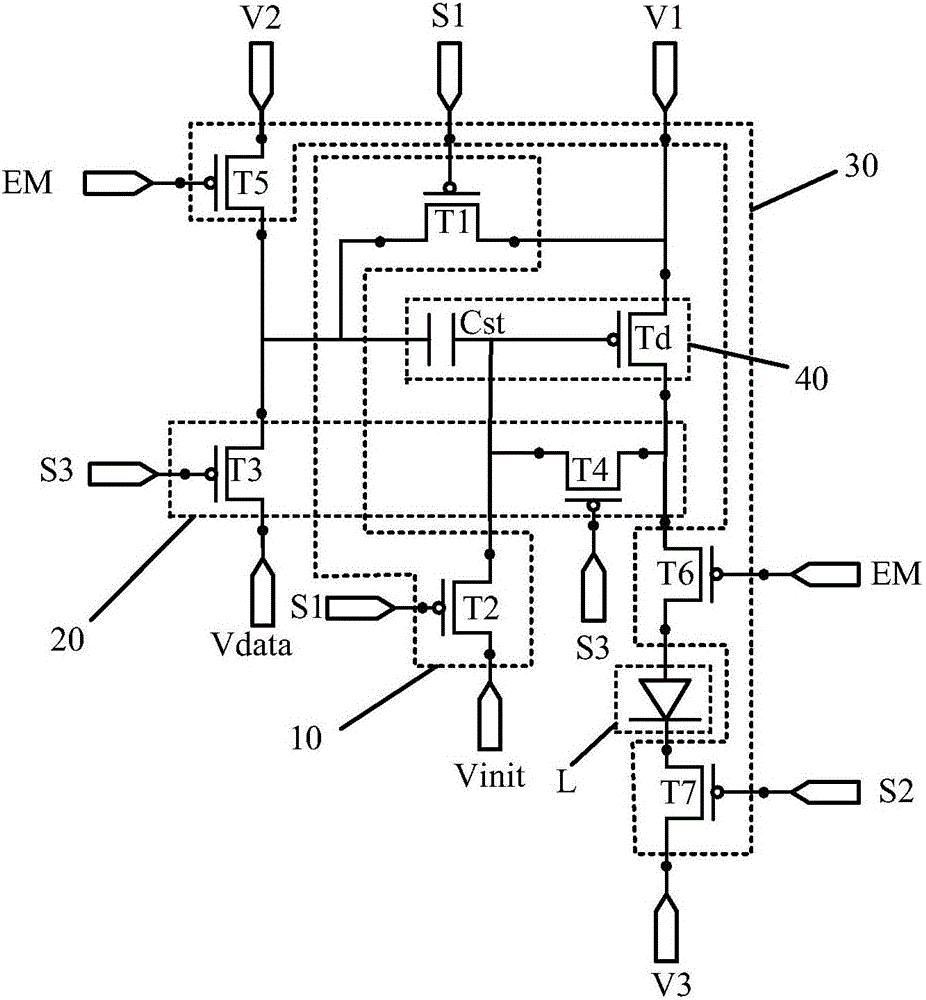

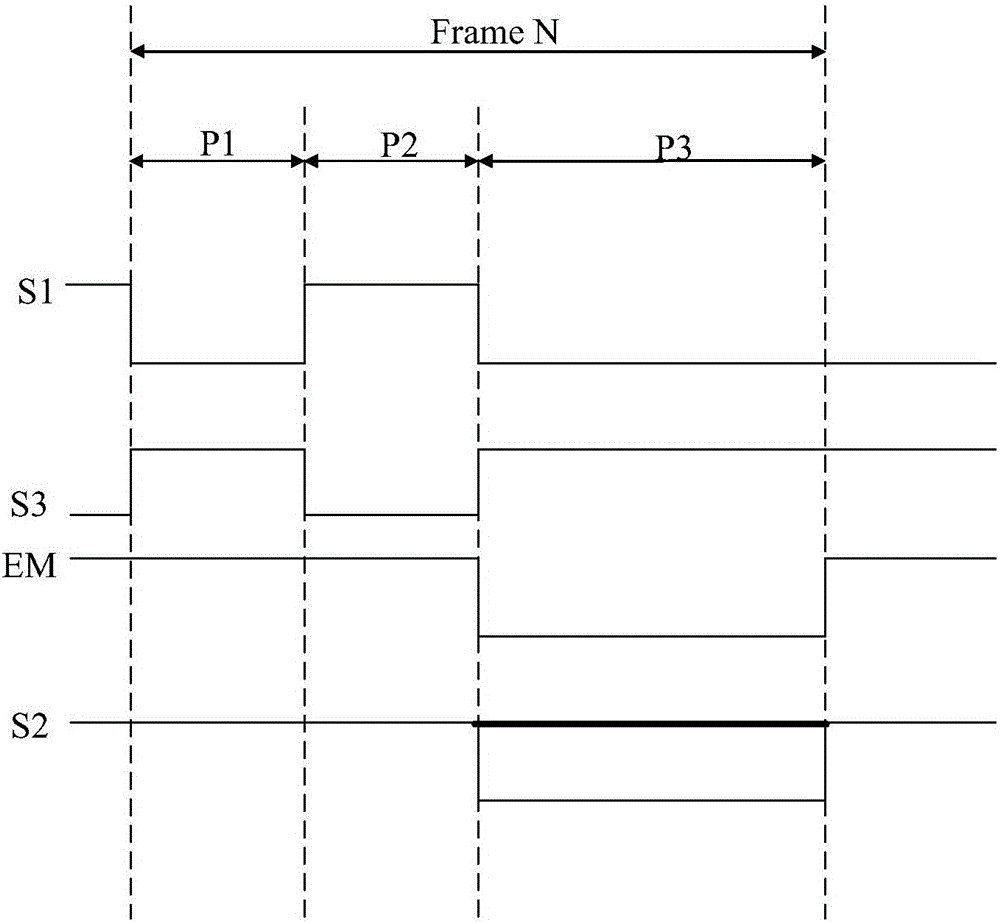

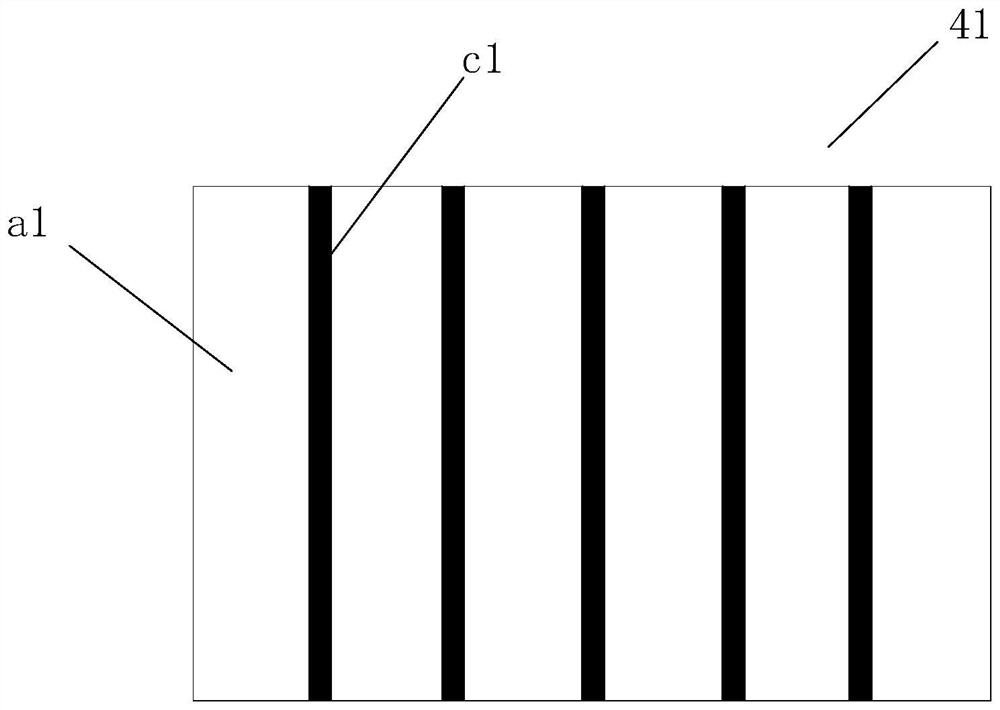

OLED pixel circuit, driving method of OLED pixel circuit and display device

ActiveCN106652903AUniform openingAvoid flickeringStatic indicating devicesDisplay deviceComputer science

The invention relates to the technical field of display, and in particular relates to an OLED pixel circuit, a driving method of the OLED pixel circuit and a display device. The phenomenon of screen splashing when a display panel is started up or the sleeping is awakened can be eliminated. The OLED pixel circuit comprises an initialization module, a data write-in and compensation module, a driver module and a light-emitting control module, wherein the initialization module is respectively connected to the driver module, a first signal end, a first voltage end and an initial voltage end, and is used for initializing the driver module; the data write-in and compensation module is respectively connected to the driver module, a scanning signal end and a data voltage end, and is used for carrying out compensation of threshold voltage on the driver module; the driver module is further connected to the light-emitting control module and the first voltage end, and is used for driving a light-emitting module to emit light after the compensation of the threshold voltage is obtained; and the light-emitting control module is further connected to the light-emitting module, an enable signal end, a second voltage end, a second signal end and a third voltage end, and is used for turning on or turning off the light-emitting module under the control of the enable signal end, the second voltage end, the second signal end and the third voltage end.

Owner:BOE TECH GRP CO LTD +1

Mould release agent, its preparation method and its purpose

The invention provides a mould release agent, which comprises the following component: Silicon hydrogen bond-possessing polysiloxane, a dehydrogenation condensation catalyst and a solvent. The mould release agent of the present invention is semi-permanent type mould release agent, and has the advantages of simple composition, rapid solidification at low temperature, less transference of the mould release agent, less wax accumulation, convenient application, low cost and the like. The mould release agent achieves great breakthrough in the polyurethane foamed product manufacturing field, the prepared product enables uniform perforate. The invention also provides a method for preparing the mould release agent, and a purpose of the mould release agent in production of polyurethane foamed products, epoxy resin products, glass fiber reinforcement epoxy resin products, rubber products, nonsaturated polyester products and other polyurethanes products.

Owner:HENKEL KGAA

Hybrid stent with helical connectors

ActiveUS8114149B2Minimal fish scalingIncrease flexibilityStentsBlood vesselsInsertion stentMaximum diameter

The present invention is a hybrid stent design using half-slot circumferential sets of strut members with short (<1.5 mm) slot length that has minimal fish scaling and excellent stent retention and flexibility. These half-slot circumferential sets of strut members are connected one to the other with helical connectors similar to those of the Palmaz stent. One important difference in the design of the stent of the present invention is that the helical connectors are attached to every other crown (rather than connected to every crown) to further improve stent flexibility. By appropriately varying the strut width of both the connected and unconnected curved crowns to be greater at the center than at their ends, an increased radial strength can be provided for a given maximum strain that is imparted to the stent when it is expanded to its maximum diameter.

Owner:SVELTE MEDICAL SYST

Blue background and mottled spot composite Tang jun glaze and technology for preparing jun porcelain through same

The invention provides a blue background and mottled spot composite Tang jun glaze and a technology for preparing jun porcelain through the same. Firstly, casing body raw materials are smashed and molded, and a prime casing is fired; then, the prime casing is soaked into blue background glaze slurry to be subjected to glazed, and after the blue background glaze slurry attached to the surface of the prime casing is dried, mottled spot glaze slurry is applied to local points on the surface of the prime casing; after the mottled spot glaze slurry attached to the surface of the prime casing is dried, the prime casing is placed in a kiln to be fired, and then the blue background and mottled spot composite Tang jun glaze jun porcelain is obtained. According to the blue background and mottled spot composite Tang jun glaze and the technology for preparing the jun porcelain through the same, due to the fact that iron elements, copper elements and cobalt elements are added in the blue background glaze according to specific proportions and a secondary glazing mode is used, glaze layer hacking is uniform and is not prone to bursting. The technology breaks through the overglaze color or underglaze color coloring technology adopted by a common mottled spot porcelain, the economic value of the jun porcelain is creatively increased on the aspects of glaze colors and a coating, the technology represents the advanced level of the manufacturing technology in China, and the social value of the jun porcelain is improved.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

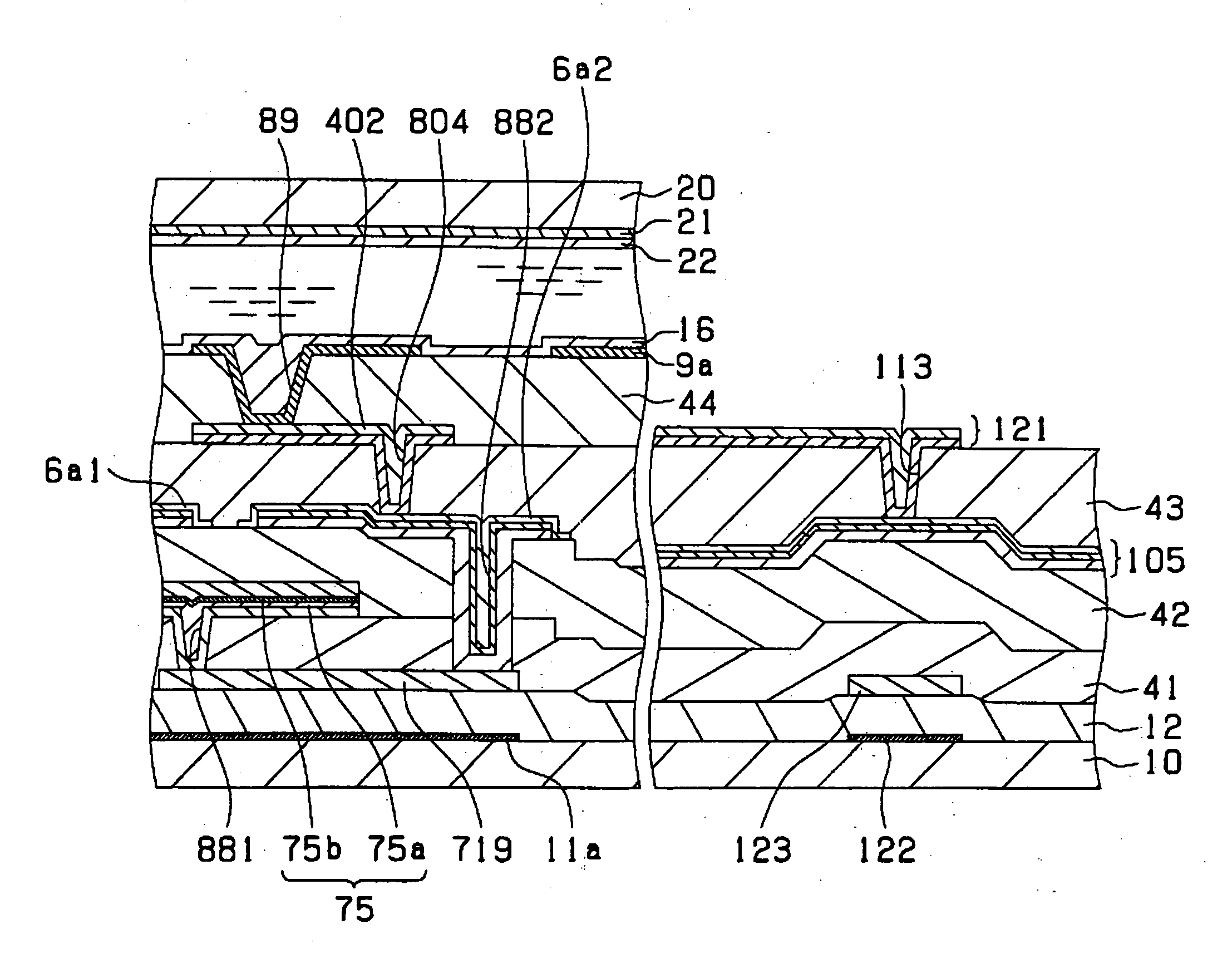

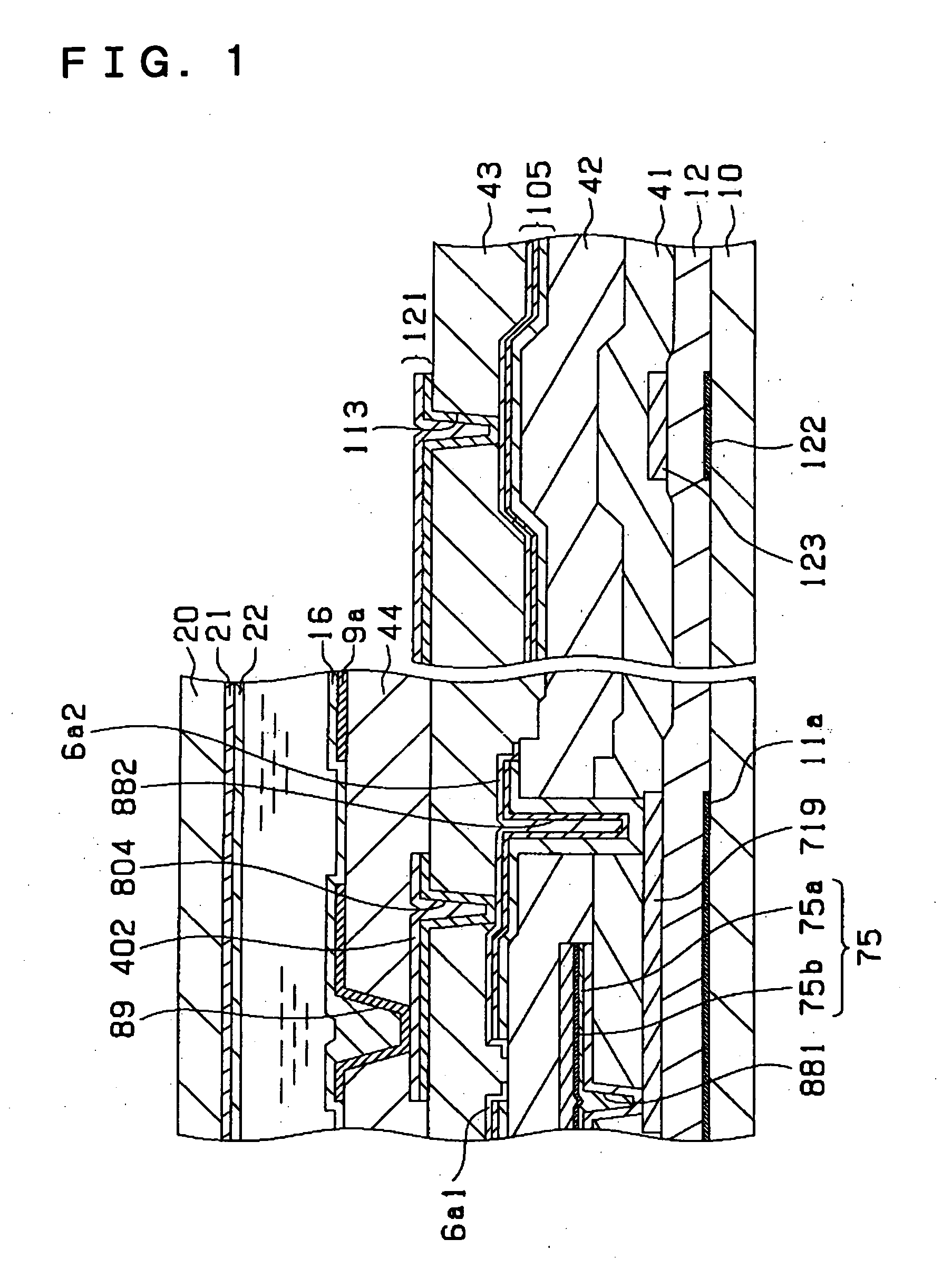

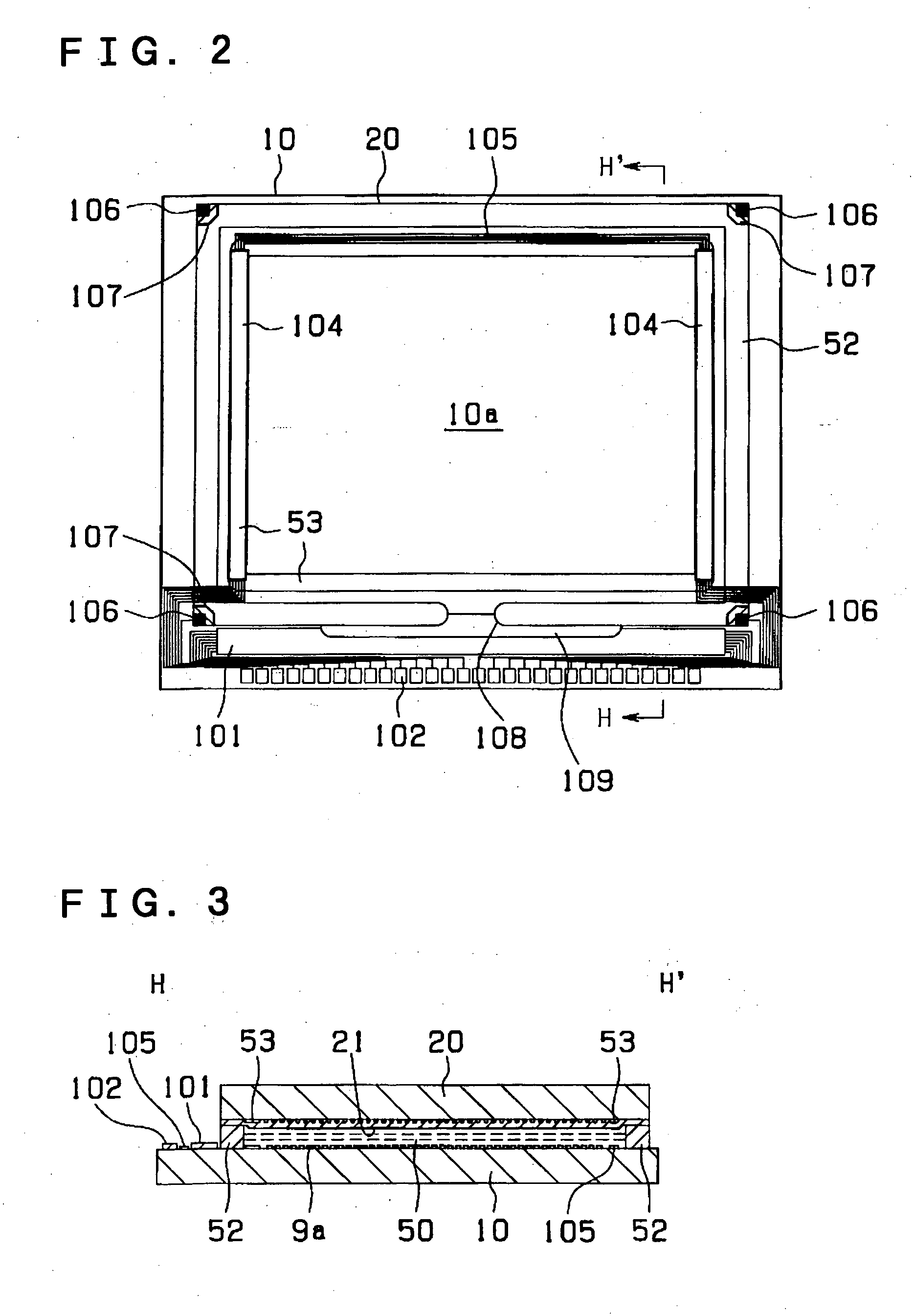

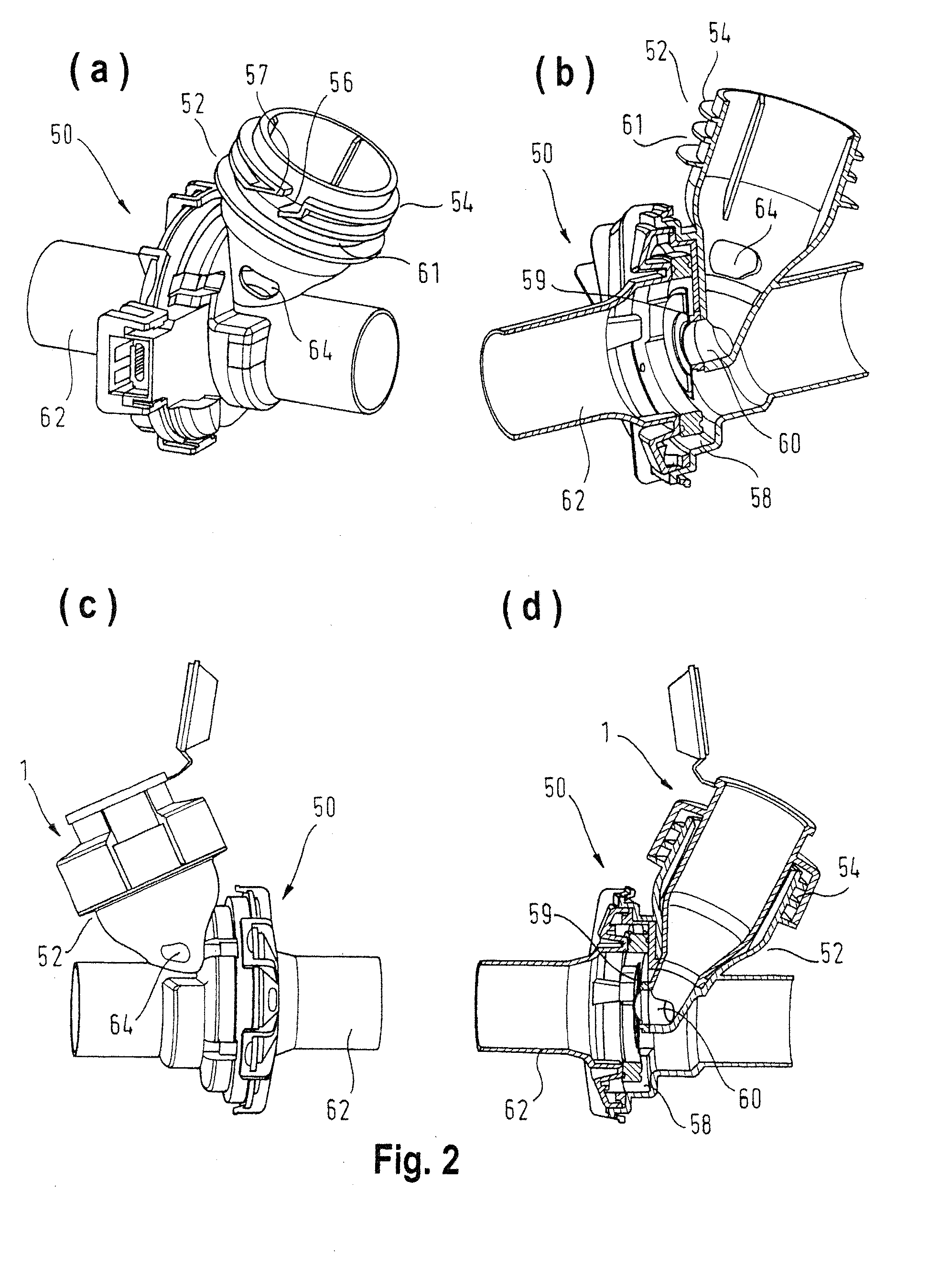

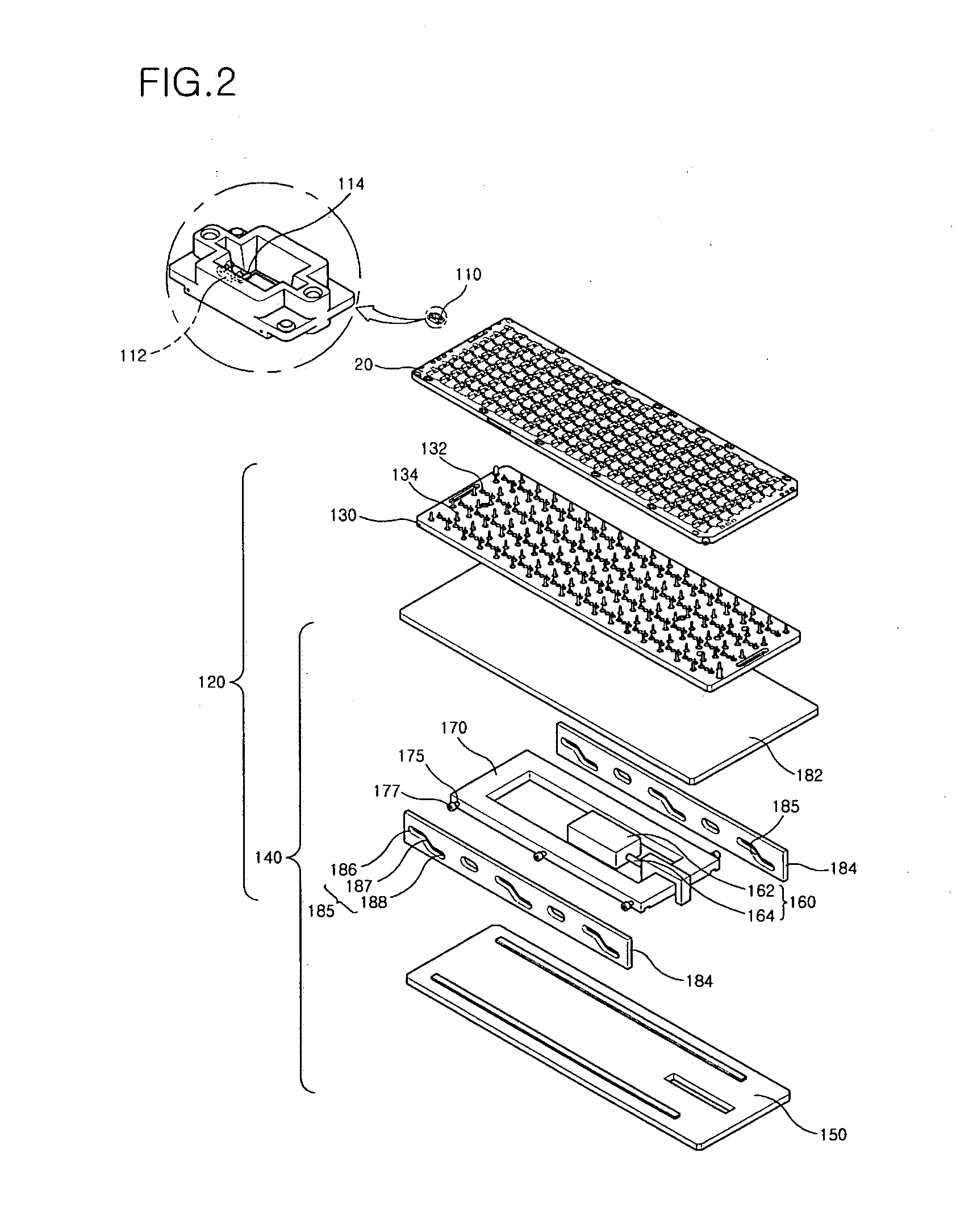

Substrate having a planarization layer and method of manufacture therefor, substrate for electro-optical device, electro-optical device, and electronic apparatus

InactiveUS20040207087A1Uniform openingImproved contact characteristicsTransistorSemiconductor/solid-state device testing/measurementElectrical and Electronics engineeringElectronic equipment

A plurality of film formation layers where film formation patterns are formed, respectively, interlayer films which are formed between the plurality of film formation layers, respectively, a plurality of sub-interlayer-film wiring patterns, which are formed in film formation layers beneath the planarized interlayer films of the interlayer films, a plurality of contact holes formed in the planarized interlayer films in order to connect the plurality of sub-interlayer-film wiring patterns and the film formation patterns of layers above the planarized interlayer films, and one or more dummy patterns which are formed on a plurality of positions under the plurality of contact holes and which are formed in one or more film formation layers under the plurality of sub-interlayer-film wiring patterns, respectively so as to control the positions of the surfaces of the plurality of sub-interlayer-film wiring patterns.

Owner:SEIKO EPSON CORP

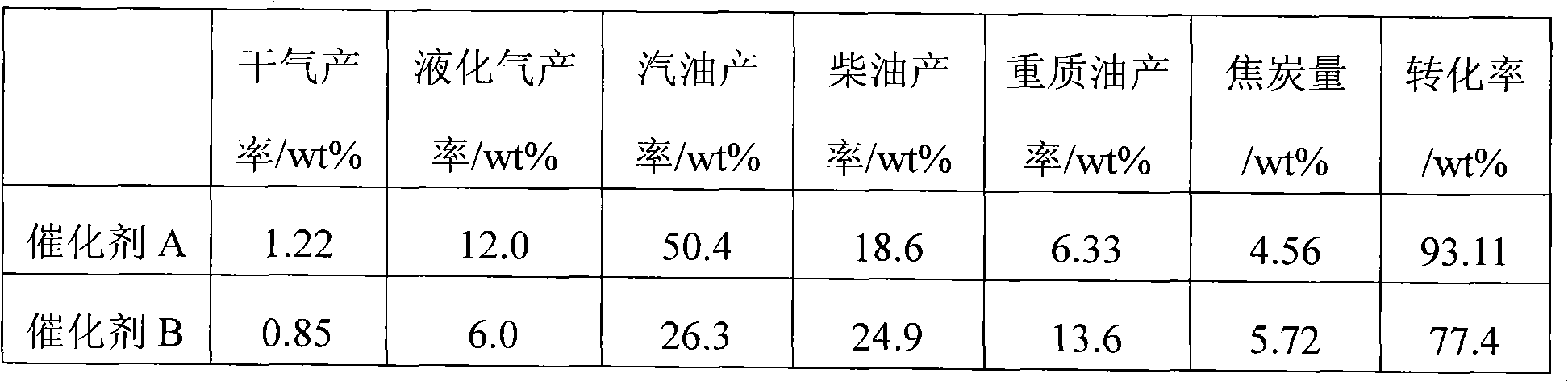

Ceramic powder composition and slurry, catalyst and carrier as well as preparation method and application

InactiveCN102010184AEasy to separateEliminate the need for separationCatalyst carriersMolecular sieve catalystsPorosityShock resistance

The invention provides a ceramic power composition, which comprises 55-95% of alumina and further comprises one or more the following components: 5-35% of feldspar powder, 5-35% of kaolin, 5-25% of zirconia, 1-10% of titanium oxide and 0.5-5% of calcium oxide. The invention further provides ceramic slurry, a ceramic catalyst carrier prepared from the slurry and application of the carrier and the catalyst in a high-viscosity reaction system. The invention overcomes the defects of poor stability, serious inactivation phenomenon, low reaction conversion rate and the like of the traditional catalyst in the reaction of the high-viscosity system, the aperture ratio of the ceramic catalyst carrier is greatly improved compared with the prior art and can even reach a millimeter scale, and meanwhile, the ceramic catalyst carrier can be maintained with higher specific surface area inside, has the properties of uniform pore opening, high porosity, heat and shock resistance, high-temperature resistance and chemical corrosion resistance, as well as excellent mechanical strength and adsorption property, can be maintained with high stability in a reaction process, can improve the conversion rate in the reaction, and is particularly suitable for the high-viscosity reaction system.

Owner:EAST CHINA UNIV OF SCI & TECH

Windproof breathable coated fabric

InactiveCN103770383AUniform openingGood coating performanceSynthetic resin layered productsCross-linkEngineering

The invention provides a windproof breathable coated fabric. The windproof breathable coated fabric comprises a base cloth layer and at least one coating, wherein a fabric formed by 170-280T warp and weft interlaced polyester filament yarns is adopted as the base cloth layer; the coating comprises the following components in parts by mass: 40-60 parts of polyurethane resin, 3-6 parts of a cross linking agent, 0.1-0.5 part of a pore-forming agent, 5-8 parts of acrylic ester, 0.5-1 part of a paint and 10-15 parts of a solvent. The windproof breathable coated fabric provided according to the technical scheme of the invention has even pores, stable performance of the coating, and excellent windproof and breathing properties, and can be used in a rigorous outdoor environment.

Owner:NANTONG QUANJI TEXTILE COATING

Preparation method of melamine-formaldehyde resin foam

The invention discloses a preparation method of melamine-formaldehyde resin foam, and belongs to the technical field of microwave foaming. The method comprises the following steps: taking 120-180 parts by weight of a melamine-formaldehyde resin; adding 5-12 parts by weight of a foaming agent, 3-6 parts by weight of an emulsifier, 3-6 parts by weight of a stabilizing agent, and 2-5 parts by weight of a curing agent in sequence, performing mixing and uniform stirring, and putting the obtained product in a microwave oven for foaming; and putting the obtained foam in an oven for curing for 2 h, wherein the temperature of the oven is 180-250 DEG C, and performing cutting molding. The melamine-formaldehyde resin foam is small in brittleness, not prone to shred particles, and high in tensile and tearing strength. The problem existing in the prior art is effectively solved, and the melamine-formaldehyde resin foam in excellent in mechanical property, flame retardance and sound attenuation.

Owner:郑州峰泰纳米材料有限公司

Complex Tang-dynasty jun glaze with white spots in blue and process for preparing jun porcelain by use of complex Tang-dynasty jun glaze

The invention discloses a complex tang-dynasty jun glaze with white spots in blue and a process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze. The process comprises: firstly crushing and molding carcass raw materials, and firing the carcass raw materials into plain carcass; then, immersing the plain carcass into slurry of glaze in blue for glazing; applying slurry of the glaze with white spots in surface points of the plain carcass after the slurry of the glaze in blue adhered on the surface of the plain carcass is dried in air; and putting the plain carcass into a kiln for firing after the slurry of the glaze with white spots is dried, thereby obtaining the complex Tang-dynasty jun glaze with white spots in blue. According to the Tang-dynasty jun glaze with white spots in blue and the process for preparing jun porcelain by use of the complex Tang-dynasty jun glaze disclosed by the invention, an iron element, a copper element and a cobalt element in special proportion are added into a glaze material of glaze in blue, and the position of the glaze with white spots is fixed by use of a secondary glazing mode. A coloring process of overglaze color or underglaze color adopted by general piebald porcelains is broken through; economic value of the jun porcelain is increased through innovation in glazing color and coating; and the jun porcelain, which is a Chinese characteristic, also represents advanced level of the production process in China, thereby increasing the social value of the jun porcelain.

Owner:JIAXIAN SHENQIAN LEGEND CERAMICS CHINAWARE FACTORY

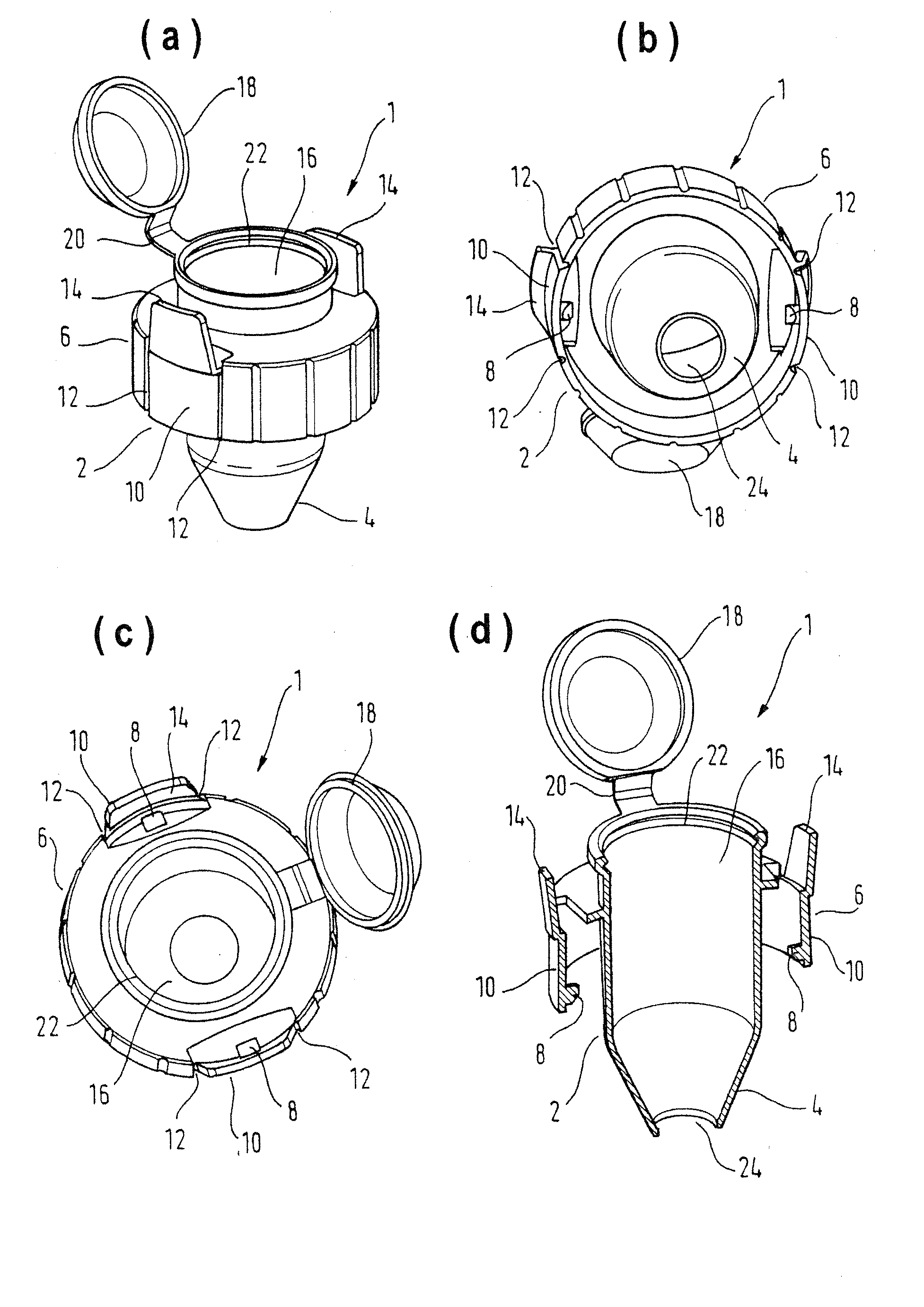

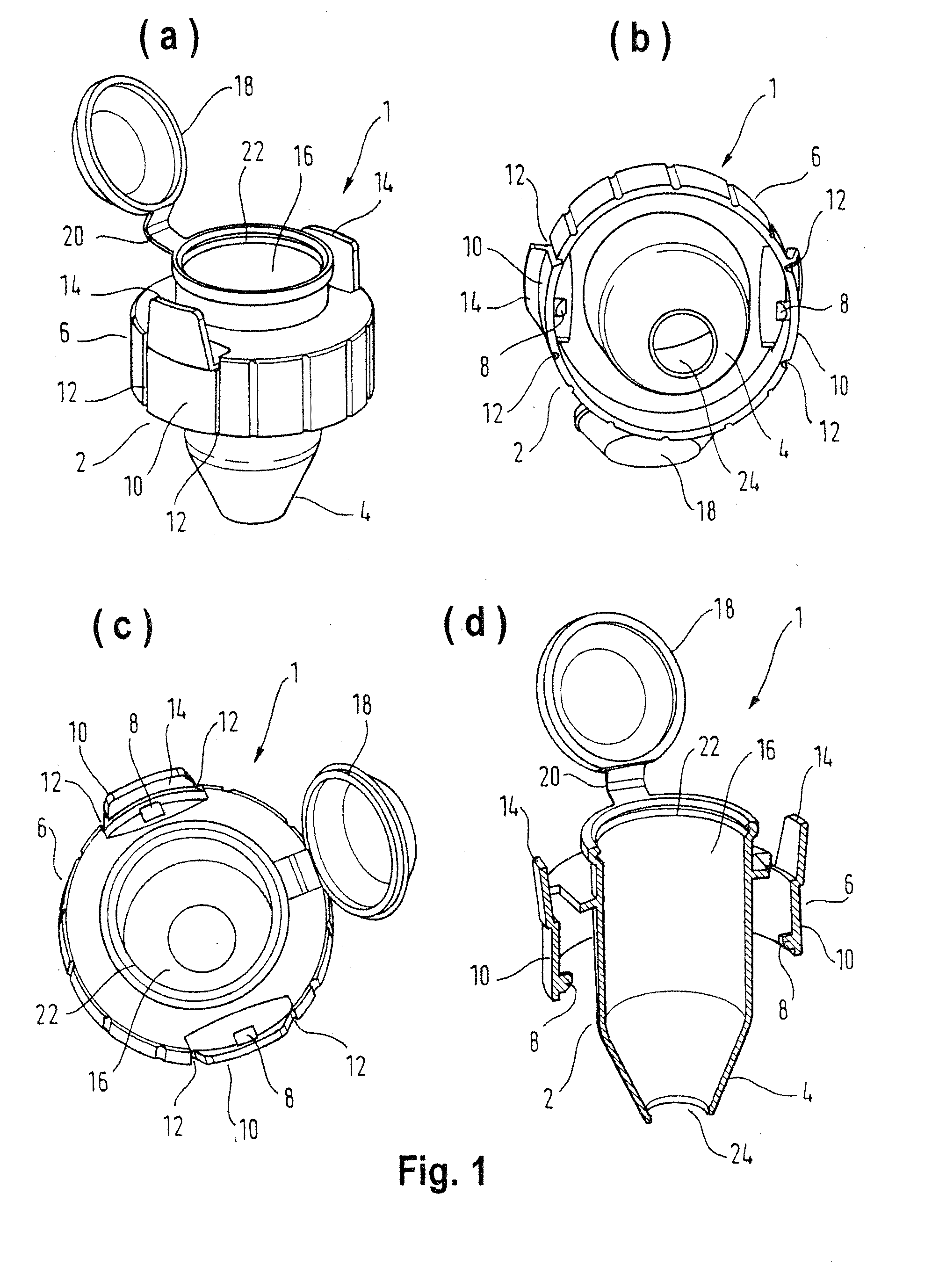

Fluid reservoir for an aerosol generation device, combination of fluid reservoir and primary fluid package, and aerosol generation device for use with the fluid reservoir

ActiveUS20160279351A1Avoid pollutionEffective treatmentRespiratorsMedical devicesBiomedical engineeringAerosol

The invention relates to a fluid reservoir (1, 100, 330, 400) which is attachable to an aerosol generation device for guiding a fluid from a fluid container (16, 116, 300) to the aerosol generation device. The fluid reservoir has an interface portion (2, 102, 202) arranged at the fluid reservoir for attaching the fluid reservoir to the aerosol generation device. The interface portion has a locking element (8, 10, 12, 14; 110, 114; 210, 214) configured to non-detachably lock the fluid reservoir to the aerosol generation device after attachment of the fluid reservoir to the aerosol generation device. The locking element is breakable to enable detachment of the fluid reservoir from the aerosol generation device. Further, the invention relates to a combination of the fluid reservoir and a primary fluid package (250), wherein the primary fluid package has at least one chamber (252, 254) containing a fluid therein. The invention also relates to an aerosol generation device which is configured for use with the fluid reservoir. The aerosol generation device has an attachment portion (52, 152) for receiving the interface portion of the fluid reservoir.

Owner:PARI PHARMA GMBH

Production process of melamine-formaldehyde resin foam sponge

The invention discloses a production process of melamine-formaldehyde resin foam sponge. The production process comprises the following steps: melamine and paraformaldehyde are taken and mixed evenly; the mixed material is conveyed into a first screw machine by a material pump, and lye is added at a feed inlet of the first screw machine; an auxiliary material solution is added to the feed end, the middle position or the tail end of the first screw machine; transparent resin extruded from an outlet of the first screw machine enters a second screw machine to be subjected to a polymerization reaction continuously in the second screw machine; the transparent resin discharged out of the tail of the second screw machine enters a third screw machine after passing through a cooling device; a foaming agent, an emulsifier, a stabilizer and a curing agent are fed from the middle of the third screw machine and mixed with the resin uniformly; the resin mixed uniformly is introduced into a microwave foaming furnace for foaming, and the melamine-formaldehyde resin foam sponge with high aperture ratio is formed. The production process of the melamine-formaldehyde resin foam sponge has high utilization rate and high yield, the melamine-formaldehyde resin foam sponge with stable production quality can be produced continuously, and the aperture ratio is high.

Owner:郑州峰泰纳米材料有限公司

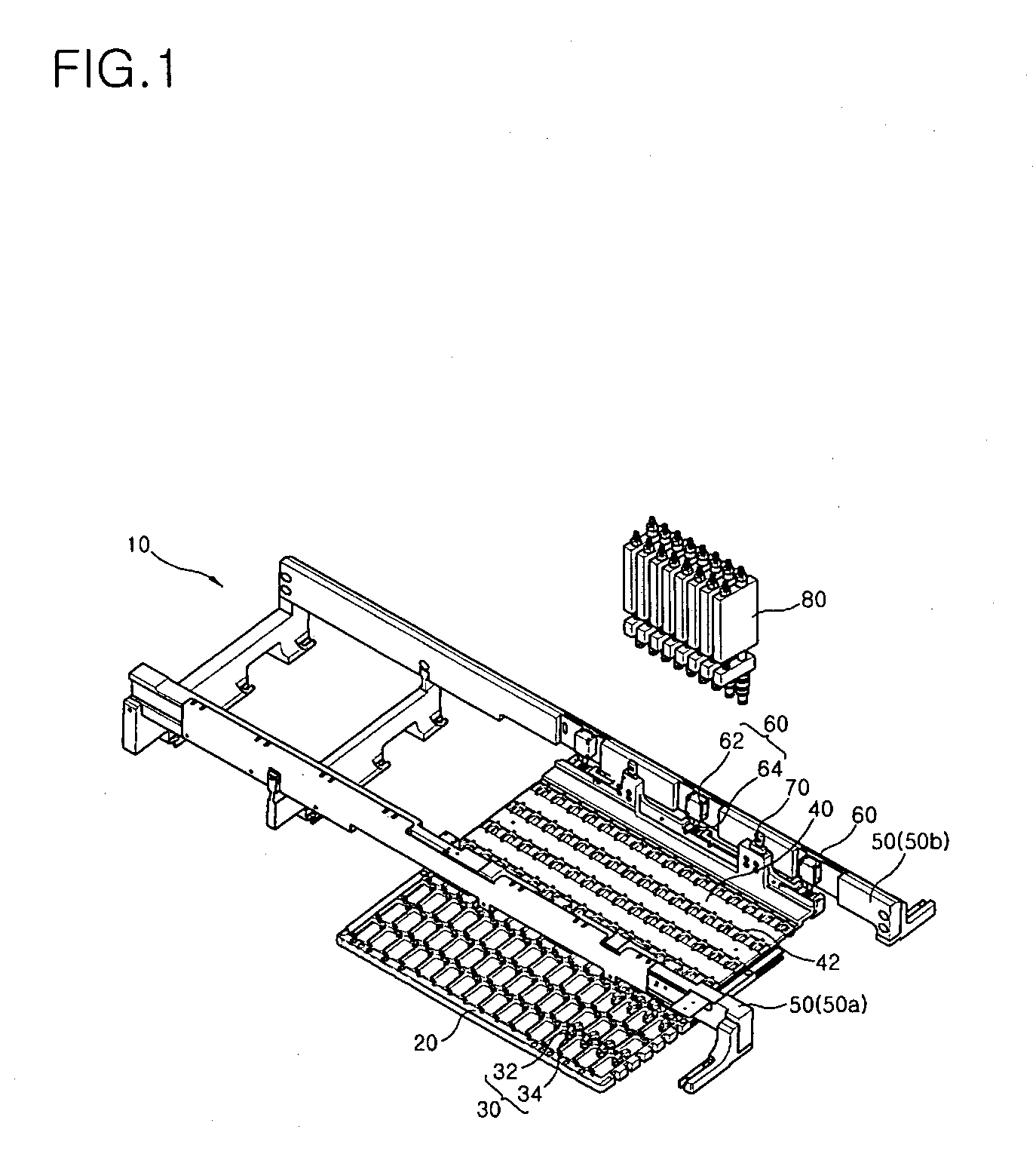

Pushing block and and a handler with the pushing block

InactiveUS20080074120A1Precise functionConveniently takenEngagement/disengagement of coupling partsSemiconductor/solid-state device testing/measurementEngineeringVertical motion

Provided is a pushing block for use in a handle and a handler equipped with the pushing block. The pushing block includes pushing pins, provided under the test tray, each pushing the latch upwards from under the test tray to enable the latch to release the packaged chip, a first plate on which the pushing pins are provided, and an assembly changing horizontal motion into vertical motion to move the first plate vertically. Positioning of the pushing block under the test tray prevents interference between the pushing block and the picker during loading and unloading and makes it convenient to take corrective action when malfunction of the picker occurs.

Owner:MIRAE CORPORATION

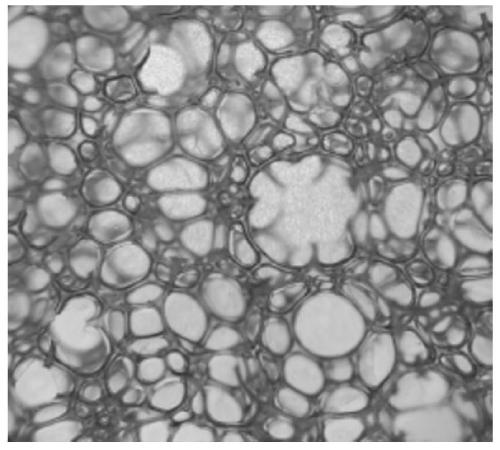

Open-cell polyurethane foam and preparation method thereof

The invention relates to the field of automobile fittings, is polyurethane foam for seats in vehicles, and concretely relates to open-cell polyurethane foam and a preparation method thereof. The open-cell polyurethane foam is mainly prepared by a first component and a second component, and the weight ratio of the first component to the second component is 100:30-40. The first component is mainly prepared by the following components in parts by weight: 20-70 parts of polyether polyol, 20-70 parts of polymer polyol, 0.5-5 parts of a cross-linking agent, 2-6 parts of a foaming agent, 0.25-3 parts of a foaming auxiliary agent, 0.8-1.2 parts of a foam stabilizer, and 0.5-10 parts of a cell opener. The second component comprises toluene diisocyanate. The preparation method comprises the following steps: the first component is firstly prepared, the first component and the second component are mixed in order to prepare polyurethane foam, and after standing, the open-cell polyurethane foam is obtained. Good bearing performance of the polyurethane foam is guaranteed, and at the same time good permeability is also provided.

Owner:CHONGQING DEYING AUTO PARTS CO LTD

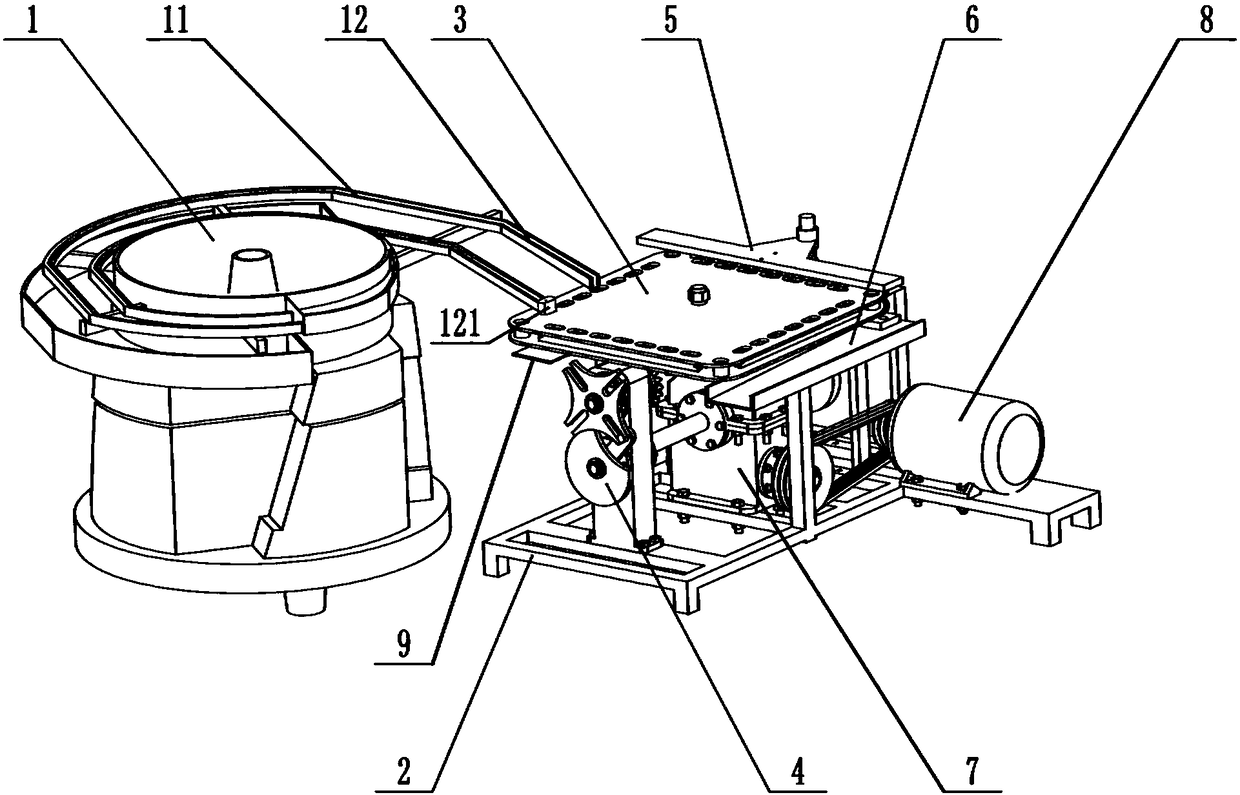

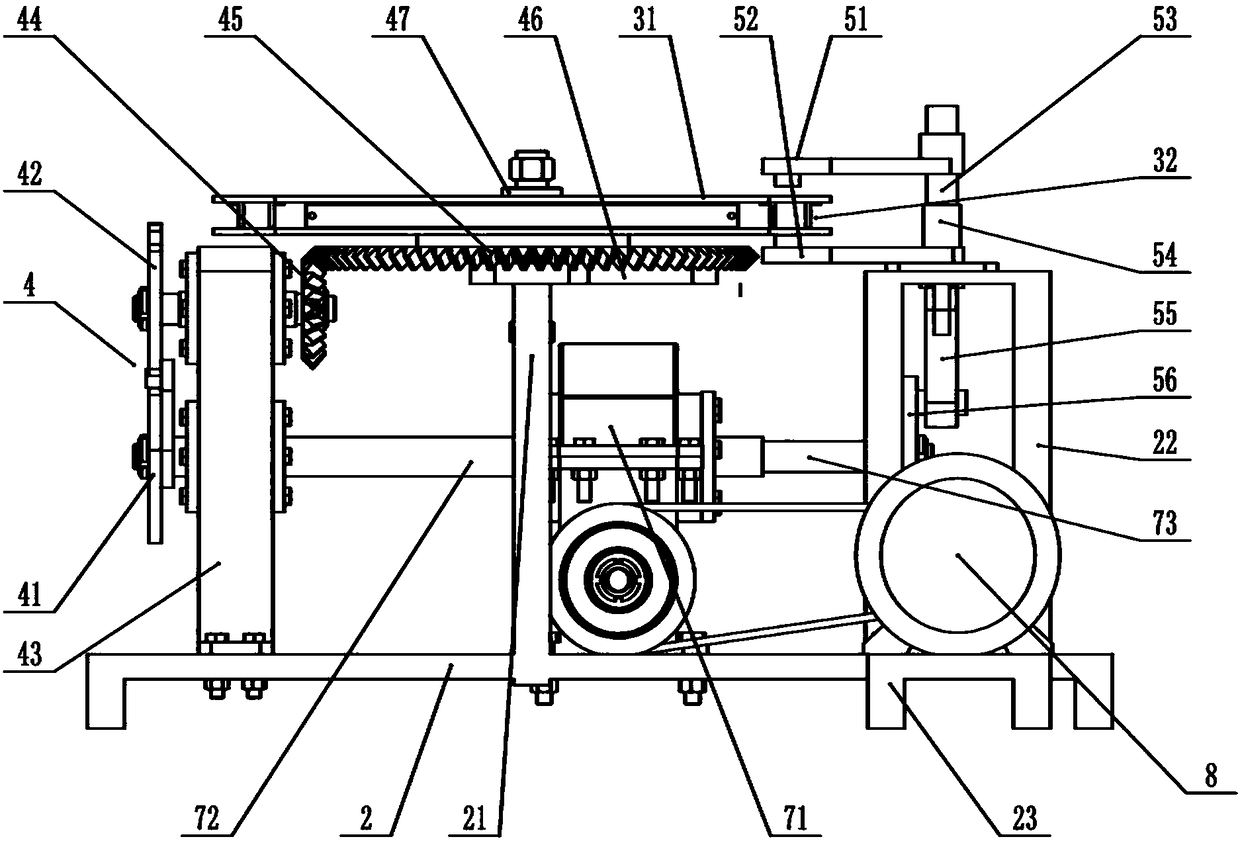

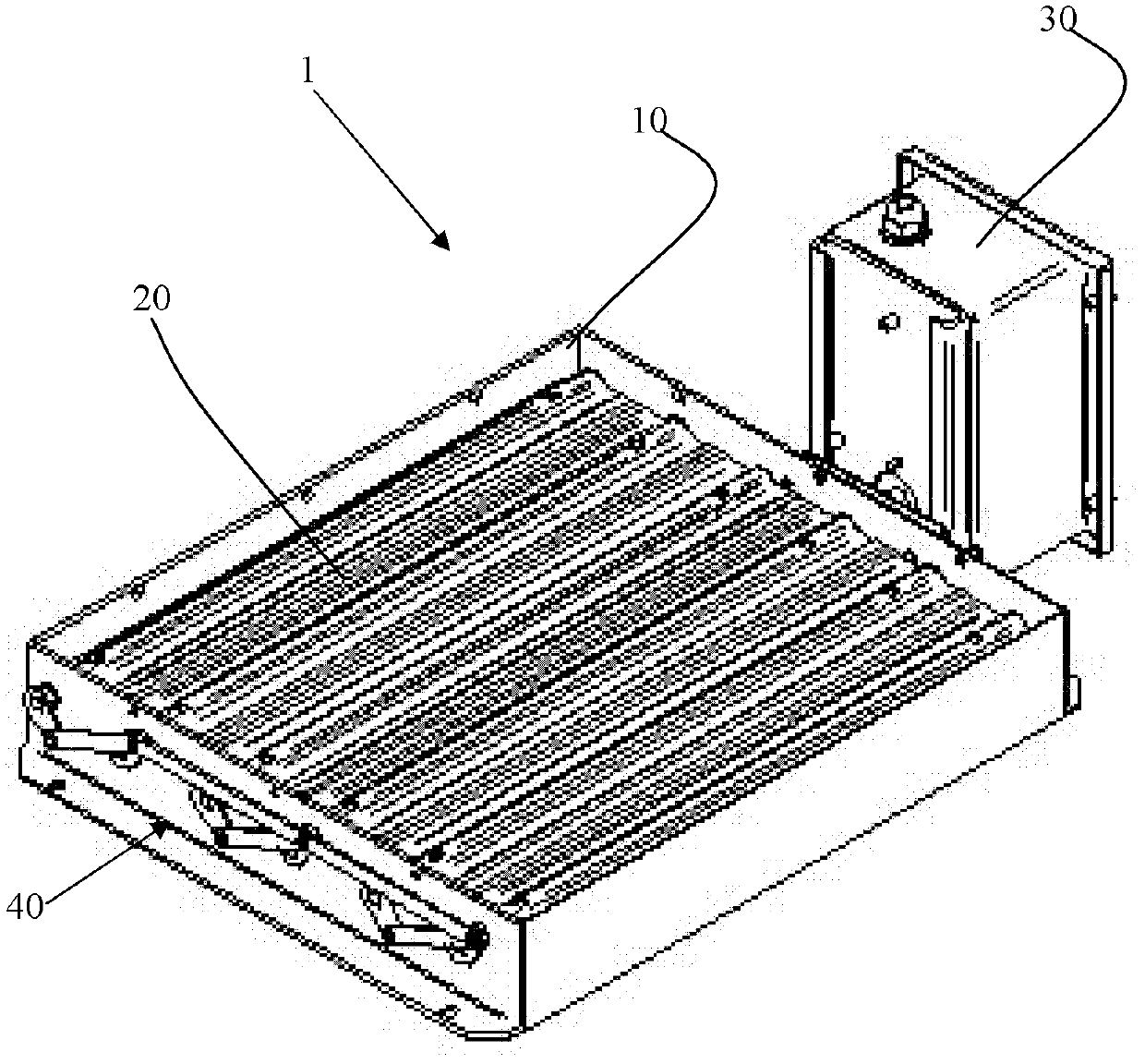

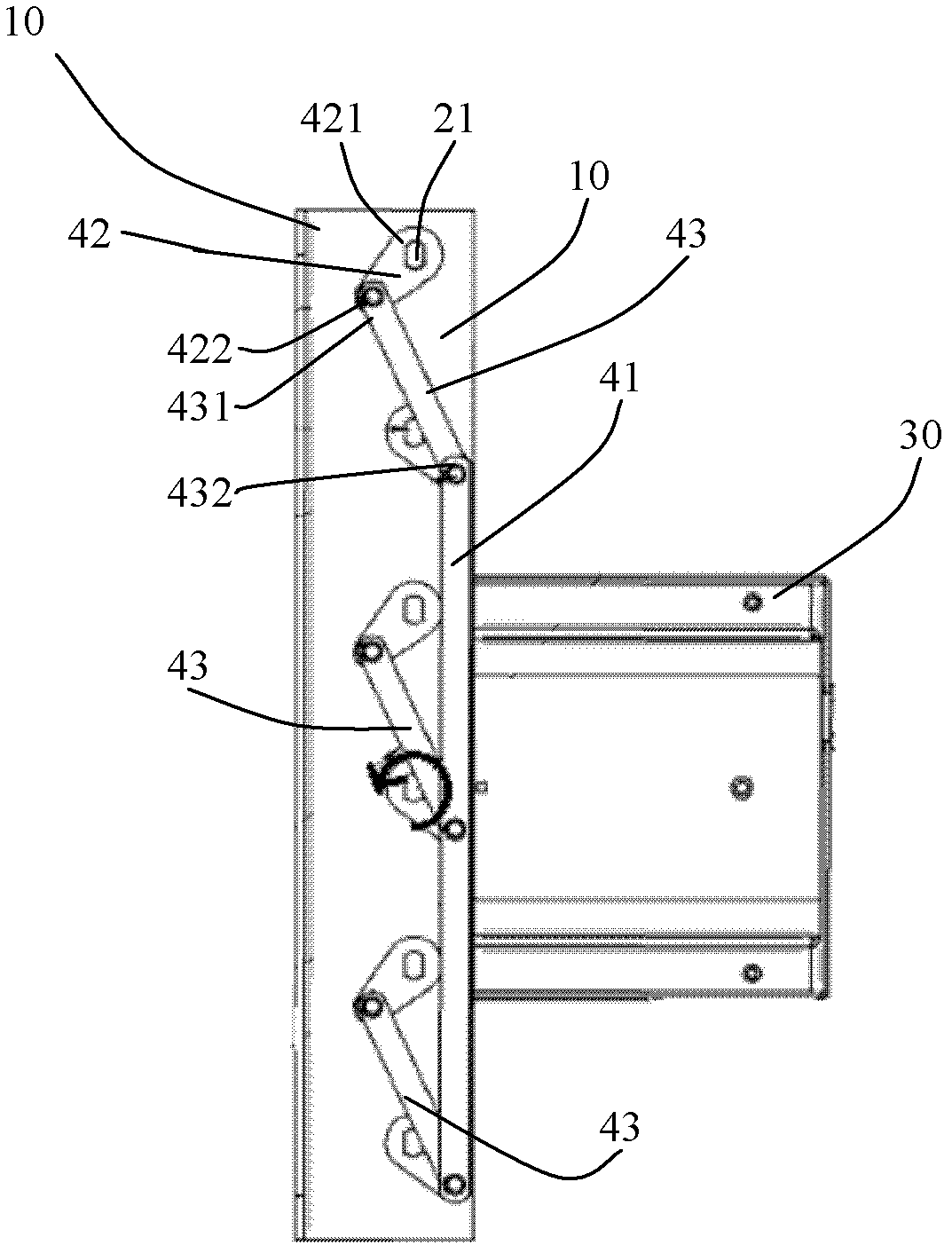

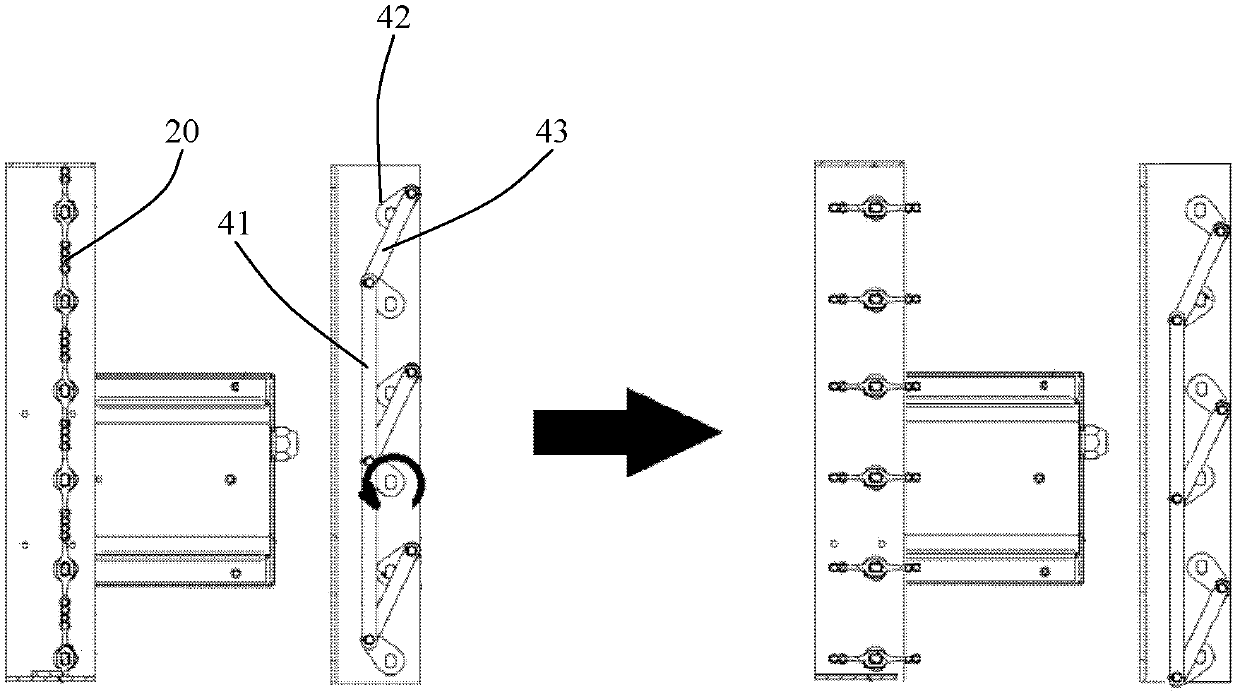

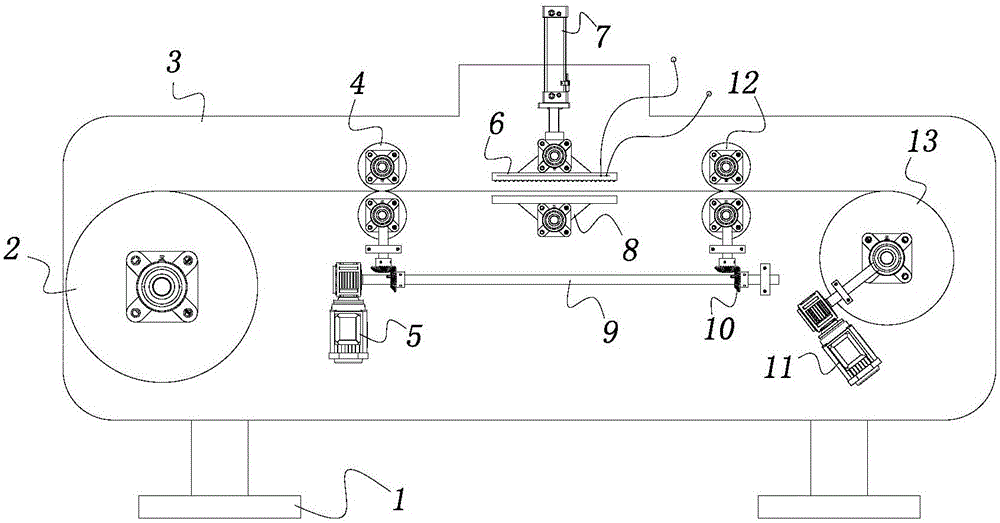

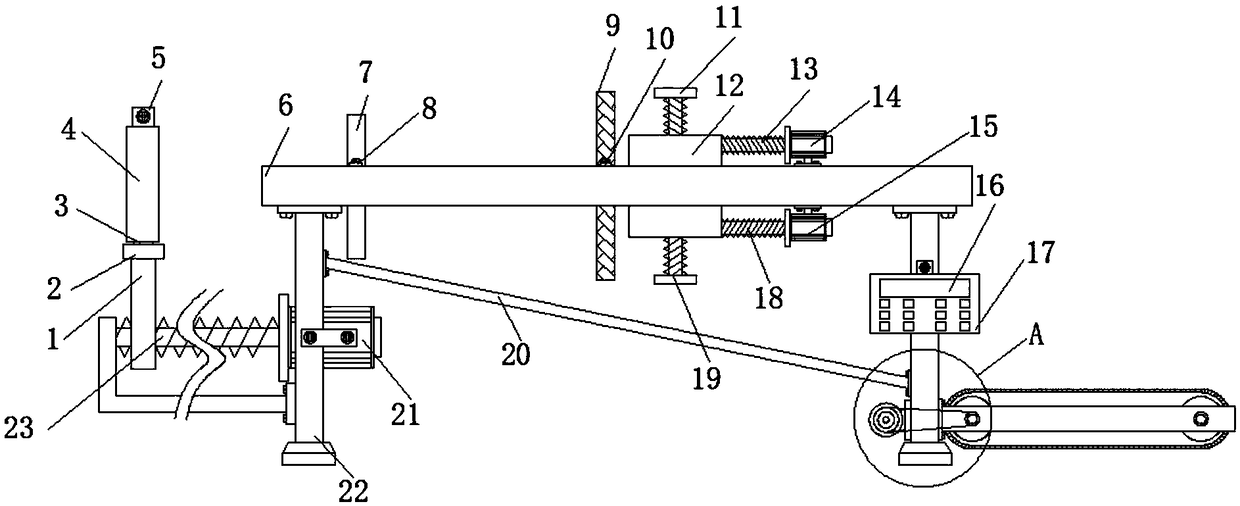

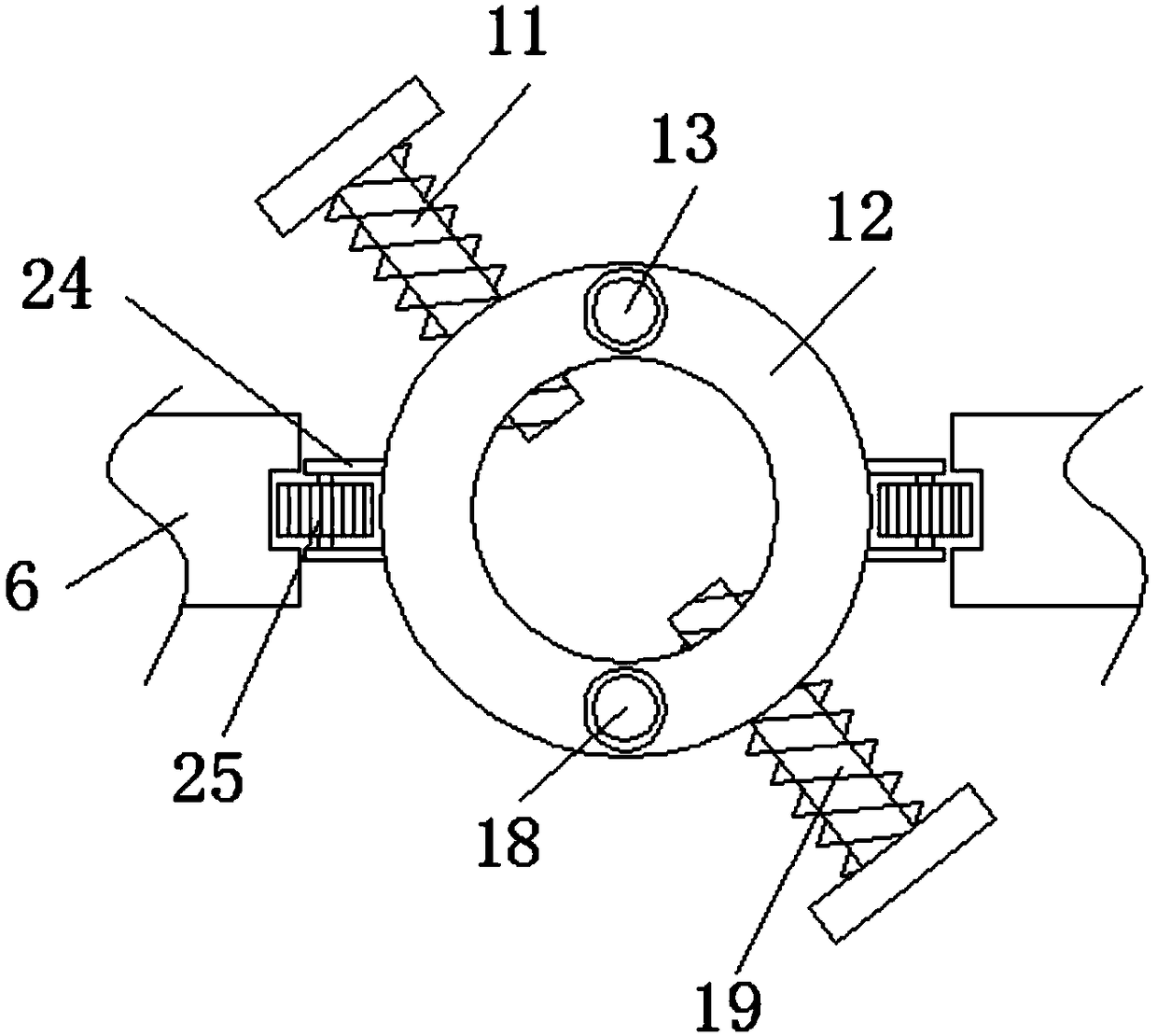

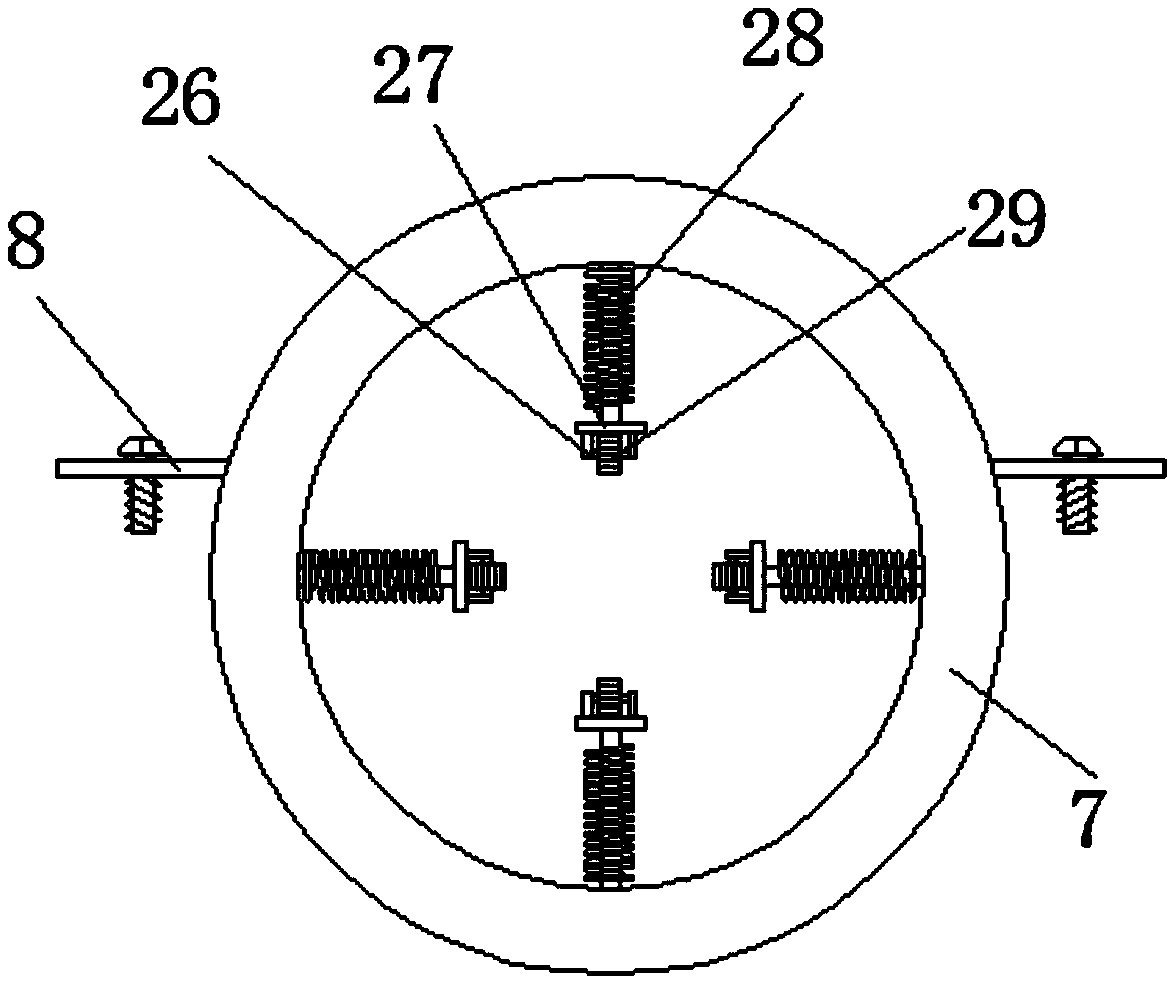

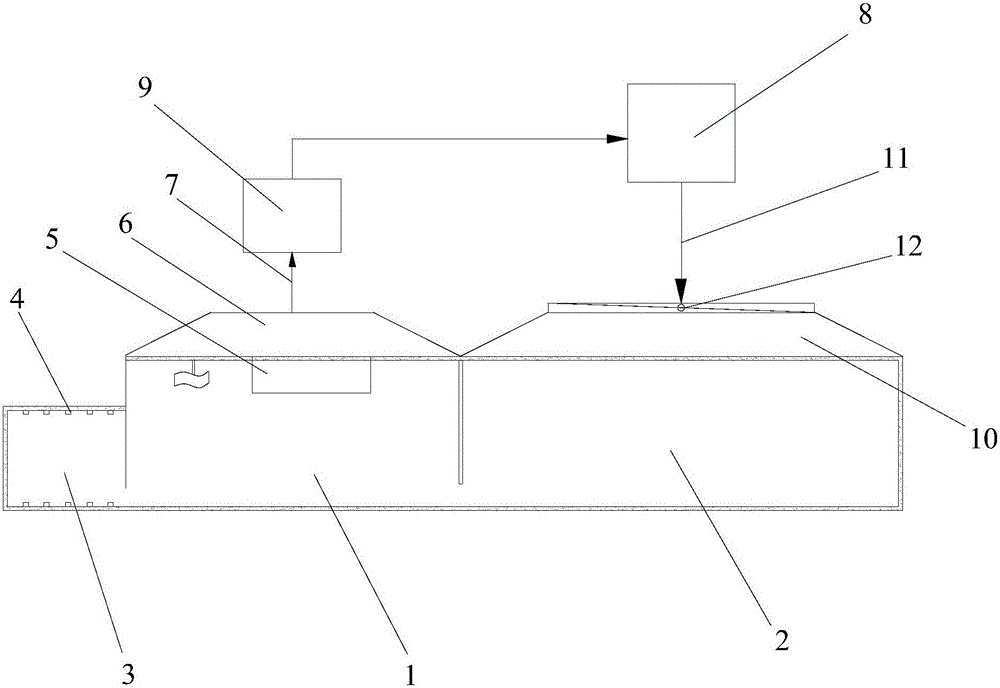

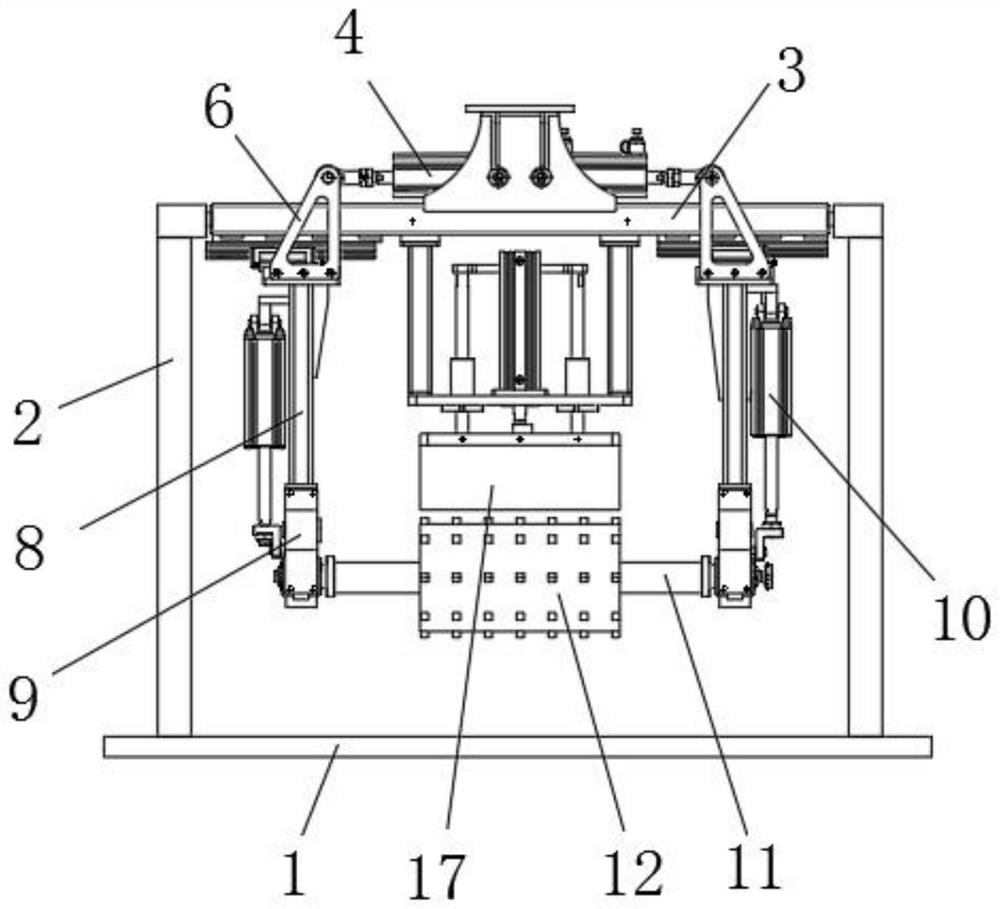

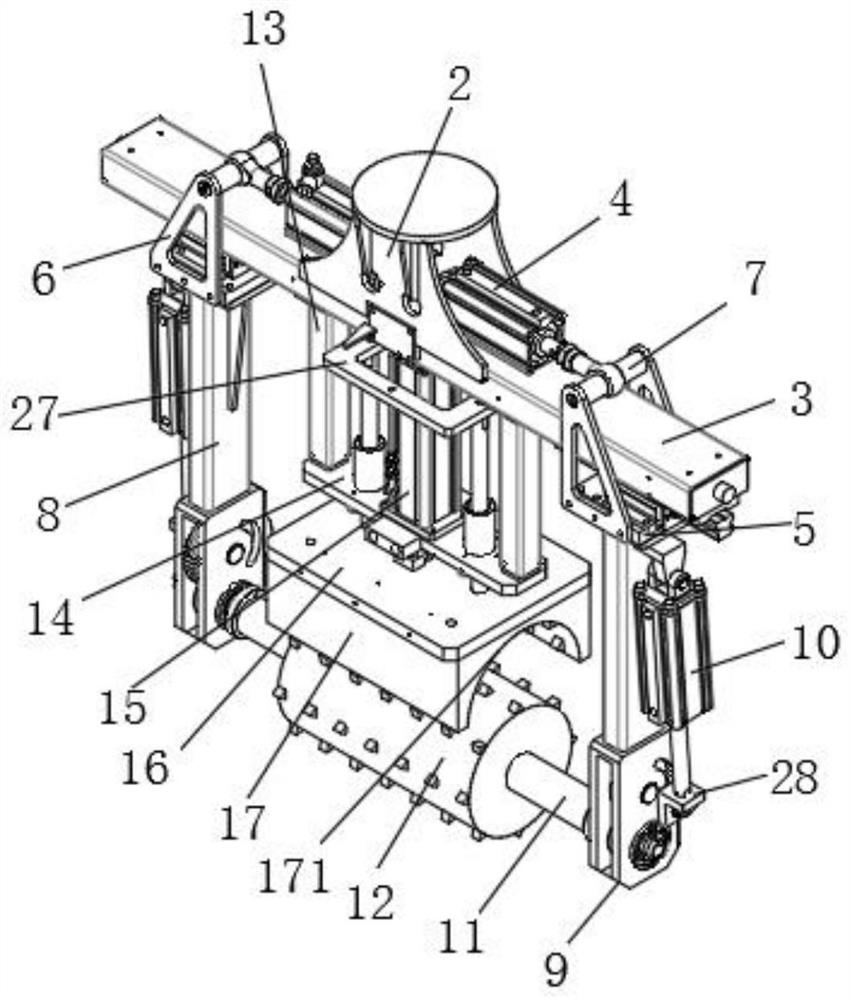

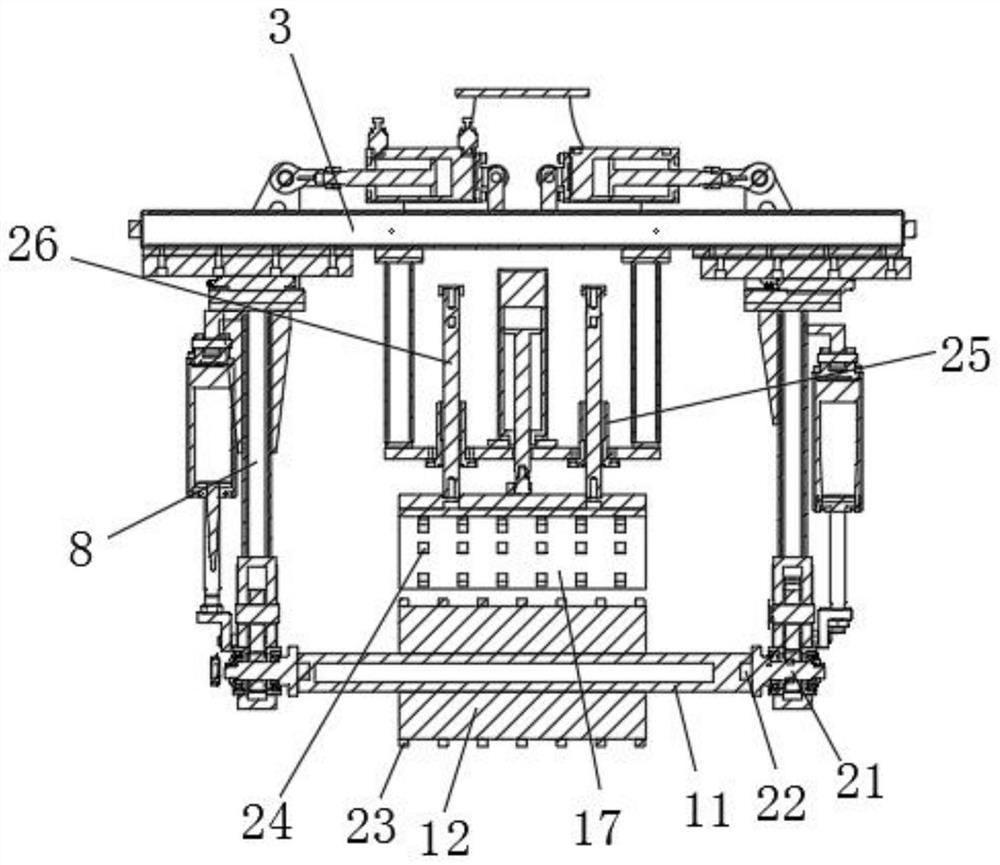

Device for forming opening in pistachio and capable of performing feeding based on vibrating disk

InactiveCN108497509ASolve problems that require manual processingSolve the problem of manual processingHuskingHullingEngineeringMechanical engineering

The invention discloses a device for forming an opening in a pistachio and capable of performing feeding based on a vibrating disk. The device comprises a feeding mechanism, a machine frame, a material bearing mechanism, a charging mechanism, an opening forming mechanism and a discharging mechanism, wherein the material bearing mechanism, the charging mechanism and the opening forming mechanism are arranged on the machine frame; the material bearing mechanism is connected with the charging mechanism; the charging mechanism and the opening forming mechanism are connected with a transmission mechanism; the discharging mechanism is arranged under the material bearing mechanism; the transmission mechanism is connected with a power mechanism; the feeding mechanism is the vibrating disk; a plurality of discharging channels are formed in the vibrating disk; each discharging channel is connected with a corresponding sliding rail; a clamping mechanism is arranged in the material bearing mechanism; the power mechanism is used for driving the opening forming mechanism and the feeding mechanism to move through the transmission mechanism; and an auxiliary material bearing plate is also arrangedunder the material bearing mechanism. Through the adoption of the device disclosed by the invention, the problems that in the prior art, the pistachio is vertically arranged, so that the direction isnot liable to control, an opening formed through extrusion does not confirm to specification, and the effect of manual opening forming is not achieved are solved.

Owner:于洋

Process for producing melamine foam sponge

The invention discloses a process for producing melamine foam sponge, comprising the steps of mixing well melamine and paraformaldehyde; pumping the mixture to a first screw unit by a material pump, and adding alkali liquid to a feed port of the first screw unit; adding auxiliary solution to the feed end, middle or tail end of the first screw unit; feeding to a second screw unit, transparent resin extruded from an outlet of the first screw unit, and continuing polymerization in the second screw unit; allowing transparent resin from the tail of the second screw unit to pass through a cooling device and then enter a third screw unit; introducing a foaming agent, an emulsifying agent, a stabilizer and a curing agent from the middle of the third screw unit, and mixing well with the resin; introducing the mixed resin to a microwave foaming furnace for foaming to form high-porosity melamine foam sponge; the process of the invention makes high use of materials, has high yield, and can provide continuous production of melamine foam sponge with stable quality and high porosity.

Owner:郑州峰泰纳米材料有限公司

Preparation method of melamine resin foam

The invention discloses a preparation method of melamine resin foam, and belongs to the technical field of microwave foaming. The steps of the preparation method includes mixing the material: by weight, taking 120-180 parts of melamine formaldehyde resin, in sequence adding 5-12 parts of foaming agent, 3-6 parts of emulsifier, 3-6 parts of stabilizer, 2-5 parts of curing agent, mixing then stirring evenly; pre-frothing: putting the mixture into the pre-frothing microwave oven to pre-froth, the duration for pre-frothing is 1-3 minutes; frothing: transferring the mixture into the microwave oven again to froth, the duration for frothing is 2-10 minutes; curing and cutting: then putting the foam into a baking oven to cure, keeping the oven temperature at 180-250 DEG C, after two hours cutting the foam into desired shape. The melamine resin foam is small in brittleness; the powder does not easily come off, the foam has high stretching and tearing intensity. The preparation method provides an effectively solution to problems present in existing technology, and equips melamine formaldehyde resin foam with excellent mechanical property and flame retardation and noise reduction property.

Owner:郑州峰泰纳米材料有限公司

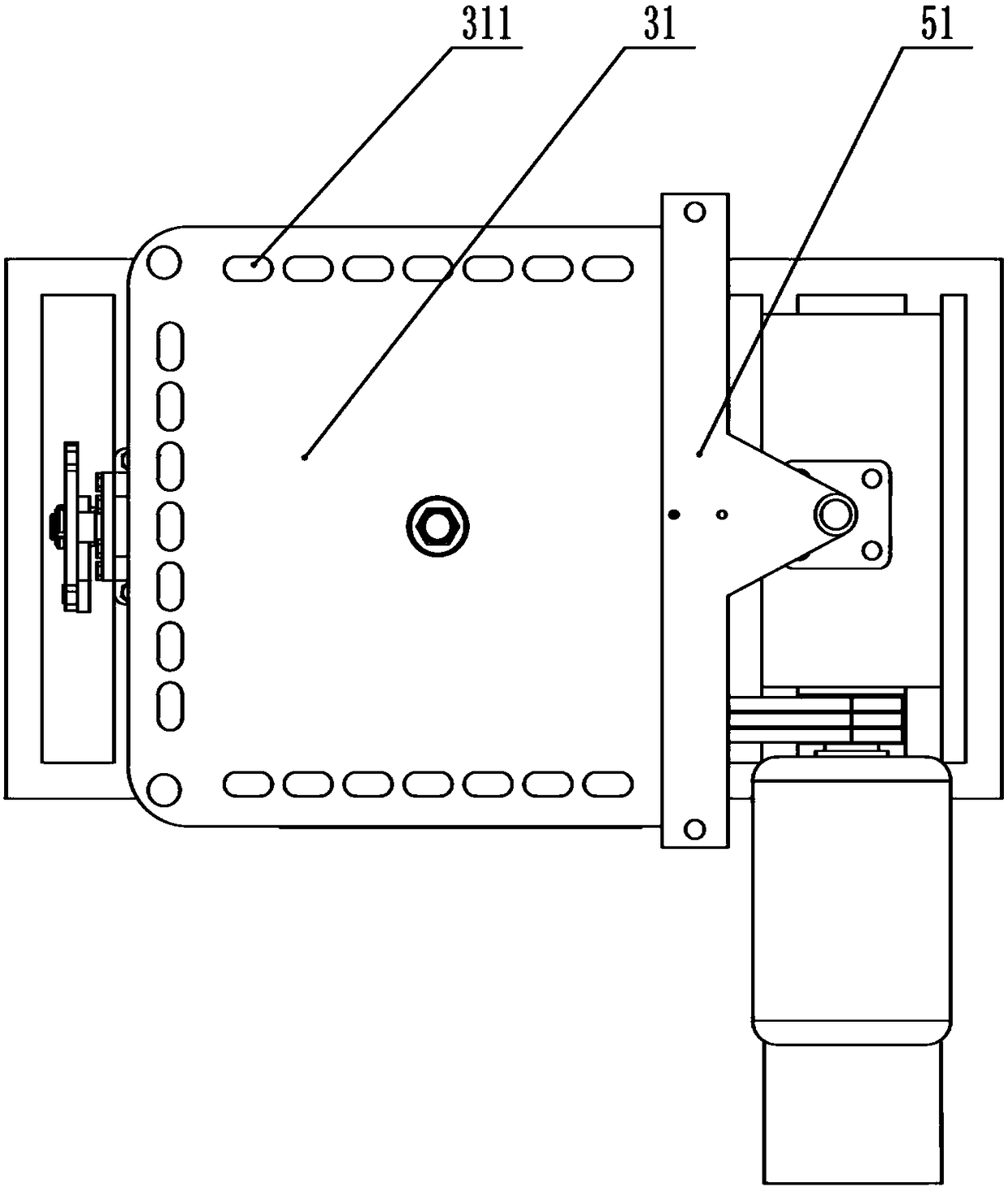

Throttle driving device

InactiveCN103292443AUniform openingEven airflowRailway heating/coolingAir-flow control membersEngineeringProcessing cost

The invention discloses a throttle driving device which comprises a drive rotating block and a plurality of driven rotating blocks; a first end of the drive rotating block is connected with a power input shaft; first ends of the driven rotating blocks are respectively connected with a power output shaft; and second ends of the driven rotating blocks are connected with a second end of the drive rotating block through a link assembly. Furthermore, the link assembly comprises a main link and a plurality of auxiliary links; and the main link is connected with the second end of the drive rotating block and the second ends of the driven rotating blocks through the auxiliary links. Throttle blades are driven to be automatically opened by the throttle driving device, the openings of the blades of the throttle can be guaranteed to be uniform, the air flows smoothly, and meanwhile, the processing cost is lowered considerably.

Owner:SHANGHAI WEIPANG IND

Novel perforated film processing machine

The invention relates to a novel perforated film processing machine. The novel perforated film processing machine comprises two side plates which are supported by columns and are arranged opposite to each other, wherein an unreeling shaft is arranged between the head ends of the two side plates and a reeling shaft is arranged between the tail ends of the two side plates; the unreeling shaft and the reeling shaft are of three-section structures; a reeling motor which drives the reeling shaft is further mounted on the side plates; a first clamping roll set, a perforating device and a second clamping roll set are arranged between the middle parts of the two side plates along the moving direction of a film; both the first clamping roll set and the second clamping roll set, which are same in structure, comprise upper rolls and lower rolls; the perforating device comprises an above pressing plate with salient points arranged in a matrix on the lower surface and a below supporting platform. The perforating device further comprises a vertical air cylinder which is fixedly mounted on the side plates, wherein the pressing plate is fixedly mounted at the bottom end of a piston rod of the air cylinder. A heating device for heating the pressing plate is further comprised, and a linking device for synchronously driving the lower rolls of the first clamping roll set and the second clamping roll set is further comprised.

Owner:EULIKIND TIANJIN TECH

Mould-proof sponge material and method for preparing same

The invention discloses an anti-mold sponge material and a preparation method thereof. The above-mentioned anti-mold sponge material is made of the following components in parts by weight: 80-100 parts of polyvinyl alcohol aqueous solution, tristyrylphenol polyoxyethylene ether 11-18 parts, 2-3 parts of sodium alginate, 1-2 parts of sorbitol fatty acid ester, 1-2 parts of glutaraldehyde, 1-2 parts of polyvinyl butyral, dipentyl succinic acid sulfonate 0.2-0.8 parts of sodium bicarbonate, 0.1-0.2 parts of sodium bicarbonate, 0.1-0.2 parts of sodium silicate, 0.01-0.03 parts of azobisisobutyronitrile and 0.01-0.02 parts of carbon black. The invention also provides a preparation method of the mildew-proof sponge material.

Owner:SUZHOU YUEHU SPONGE COMPOUND FACTORY

Bamboo slicer convenient for positioning and regulating slicing amount

The invention discloses a bamboo slicer convenient for positioning and regulating slicing amount. The bamboo slicer comprises a main body, wherein one side of the main body is equipped with a pullingring; the top of the pulling ring is rotatably connected with a top fixed rod; the bottom of the pulling ring is rotatably connected with a bottom fixed rod; the two sides of the pulling ring are equipped with slide wheel fixed plates; the inner parts of the slide wheel fixed plates are rotatably connected with slide wheels; one side, adjacent to the slide wheel fixed plates, of the pulling ring is rotatably connected with a top lead screw and a bottom lead screw; the bottom lead screw is positioned below the top lead screw; and one side, away from the pulling ring, of the bottom lead screw isequipped with a bottom motor. According to the bamboo slicer disclosed by the invention, a movable rod, a top plate, a top rod, a pushing ring, a pushing motor, a pushing lead screw, a top fixed rod,a pulling ring, a top lead screw, a top motor, a bottom motor, a bottom lead screw, a bottom fixed rod, a slide wheel fixed plate and a slide wheel are arranged, so that working strength of a user isreduced, and safety guarantee of the user is improved.

Owner:黄琴

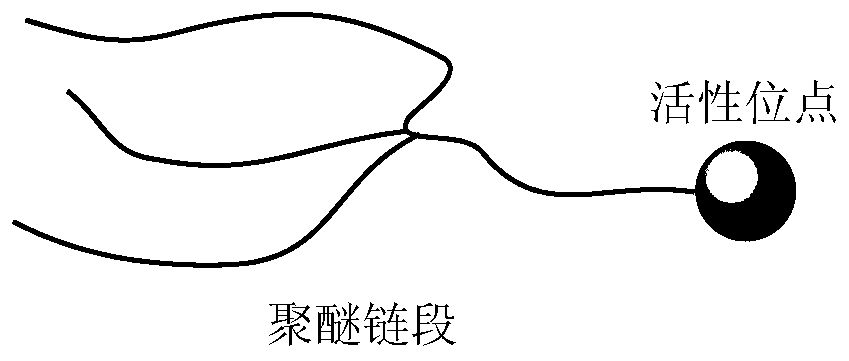

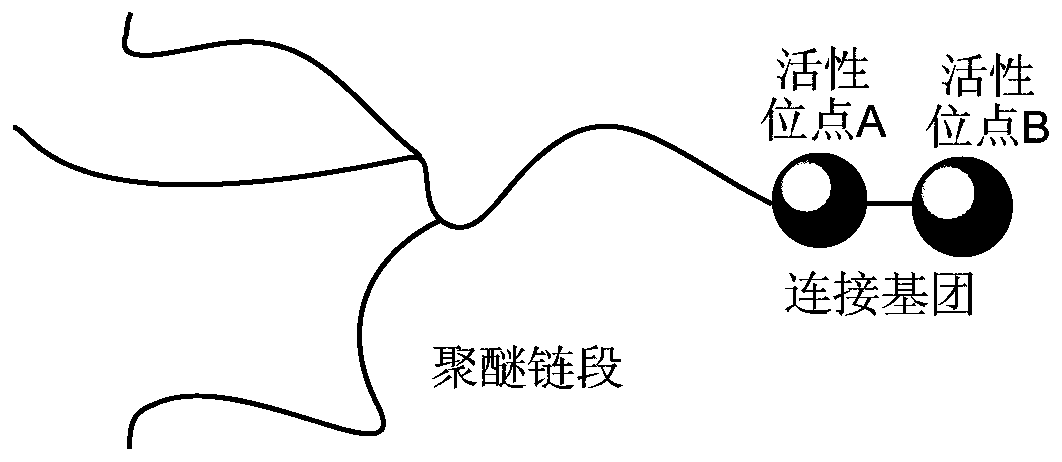

Modified polyether polyhydric alcohol and application thereof in polyurethane foam materials

The invention provides modified polyether polyhydric alcohol and an application thereof in polyurethane foam materials. The preparation method of the modified polyether polyhydric alcohol comprises the following steps of: a compound A is reacted with polyether polyhydric alcohol, the compound A is an anhydride and / or dicarboxylic acid compound containing a polymerizable double bond, which preferably selected from one or two of maleic anhydride and itaconic anhydride, maleic anhydride is preferable; 2) the product obtained in step 1) is reacted with an epoxy compound containing a polymerizabledouble bond in the presence of a catalyst to obtain the modified polyether polyhydric alcohol. The obtained modified polyether polyhydric alcohol has more active sites, the polymerizable double bond is used for end capping, the modified polyether polyhydric alcohol is used as a dispersion stabilizer to be applied to the synthesis of the copolymer polyhydric alcohol, and the modified polyether polyhydric alcohol has the advantages of better dispersion stability, filterability and low viscosity.

Owner:WANHUA CHEM GRP CO LTD

Breathable elastic composite non-woven fabric and manufacturing method thereof

PendingCN113558866AImprove breathabilityUnfetteredAbsorbent padsBaby linensPolymer scienceNonwoven fabric

The invention discloses breathable elastic composite non-woven fabric which is composed of a surface layer non-woven fabric body, a middle layer elastic film and a bottom layer non-woven fabric body, the surface layer non-woven fabric body and the bottom layer non-woven fabric body are each provided with a plurality of strip-type protruding areas and a plurality of strip-type concave areas which are transversely arranged, funnel-shaped open holes are formed in the middle-layer elastic film, and strip-type breathable channels are formed between the protruding areas of the surface layer non-woven fabric body and the bottom layer non-woven fabric body, so that internal wet and hot air can permeate into the breathable channel space formed by the bottom layer non-woven fabric body and the elastic film through the bottom layer non-woven fabric body during wearing, the wet and hot air rapidly diffuses in the length direction and the height direction of the breathable channel space in the breathable channels, enters the breathable channel space formed by the elastic film and the surface layer non-woven fabric body through the holes of the elastic film, and then is discharged out of the elastic composite non-woven fabric, so that the effect of rapid heat conduction and moisture removal is achieved.

Owner:XIAMEN YANJAN NEW MATERIAL CO LTD

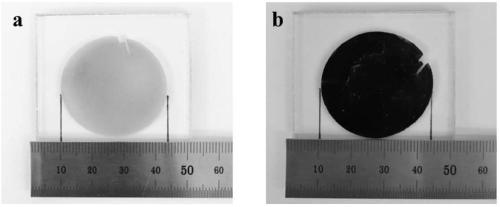

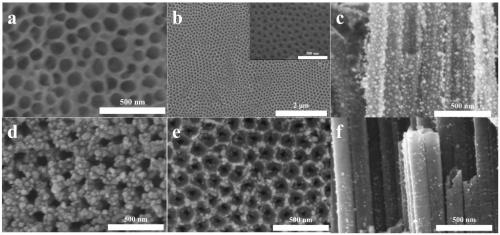

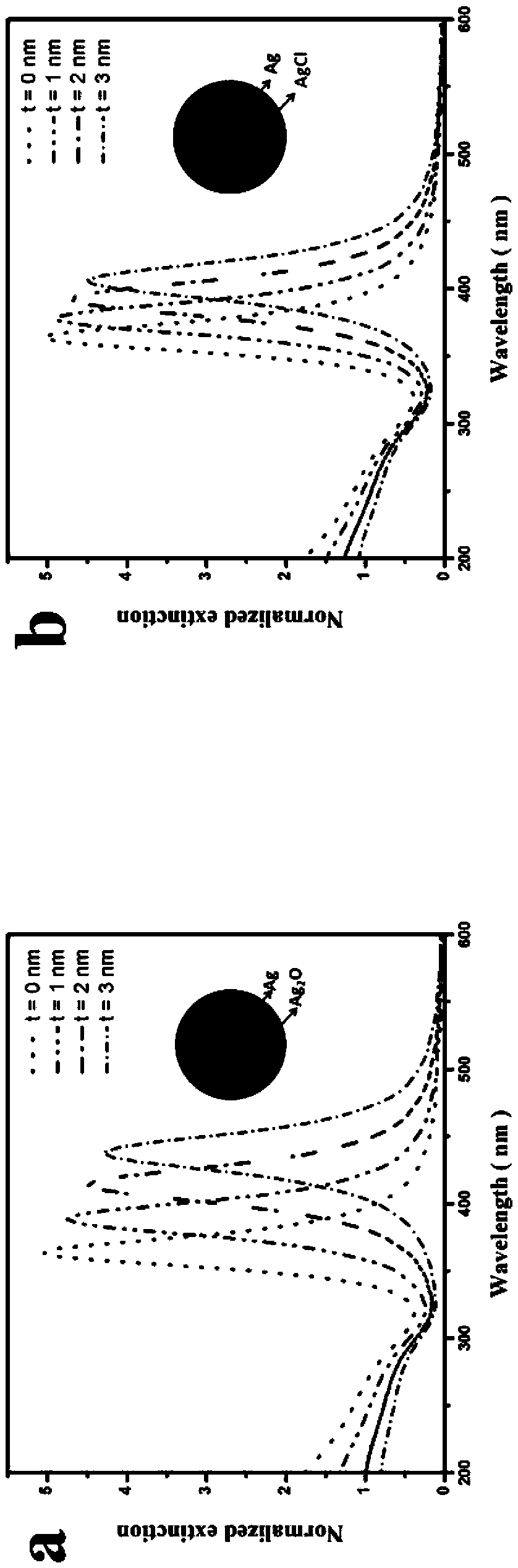

Composite material for polluted seawater desalination and preparation method thereof

ActiveCN109569592ASimple and fast operationLow costWater/sewage treatment by irradiationWater treatment compoundsControllabilitySeawater

A preparation method of a composite material for polluted seawater desalination includes following steps: step 1, preparing a titanium dioxide nanomaterial which is a large-area bi-pass titanium dioxide nanotube array thin film; step 2, preparing a silver ammonia solution and a glucose solution; step 3, preparing a titanium dioxide nano composite material modified by silver nanoparticles: utilizing the silver ammonia solution and the glucose solution prepared in the step 2 to modify the silver nanoparticles onto the titanium dioxide nanomaterial in the step 1. The preparation method is simpleand convenient in operation, low in cost and high in controllability. Silver oxide and silver chloride films can be generated when the silver nanoparticles are used and stored in actual environment, so that structure of the nanoparticles is enabled to be more stable, dielectric constant of environment in which the silver nanoparticles are positioned is enabled to be richer, and utilizable spectrumrange of the silver nanoparticles is expanded.

Owner:NORTHEASTERN UNIV

Microwave foaming device for melamine resin

InactiveCN106273195AAvoid uneven densityReduce brittlenessDirt cleaningMicrowave cavityVolumetric Mass Density

The invention discloses a microwave foaming device for melamine resin and belongs to the technical field of microwave foaming. The microwave foaming device sequentially comprises a microwave cavity and a drying and cooking cavity in the material conveying direction, wherein a pre-foaming microwave cavity is formed in the front of the microwave cavity, two rows of small microwave sources are arranged on each of the top wall and the bottom wall of the pre-foaming microwave cavity, each row comprises five small microwave sources, the power of each small microwave source is 1 kW, and a microwave source with the power being 20 kW is arranged on the top wall of the microwave cavity. The pre-foaming microwave cavity is formed in the front of the microwave cavity of the production device, pre-foaming is performed before foaming, and the problem of foam density unevenness caused by uneven radiation in the resin foaming process is effectively solved.

Owner:郑州峰泰纳米材料有限公司

High-nutrition soy sauce flavor-type marinated donkey meat and preparation method thereof

InactiveCN111631357ASolve technical problems that require manual opening and labor-intensiveReduce labor intensityMetal working apparatusMeat processing devicesBiotechnologyMonosodium glutamate

The invention discloses high-nutrition soy sauce flavor-type marinated donkey meat and a preparation method thereof. The donkey meat is prepared from the following raw materials: donkey meat, water, Baijiu, monosodium glutamate, salt, white granulated sugar, thick broad-bean sauce, star anise, cassia bark, fructus amomi, alpinia katsumadai, mint, semen plantaginis, radix angelicae, clove, wormwood, flos magnoliae liliflorae, astragalus membranaceus, cinnamon, common aucklandia roots, pericarpium citri reticulatae, liquorice, hawthorn, Chinese wolfberry, jujubes, chilies, lalang grass rhizome,walnut kernel powder, peanut powder, Chinese prickly ash, myrcia, pepper, raw ginger and cumin powder. The method comprises the following steps: cleaning the donkey meat, punching the donkey meat, preparing soup, pre-cooking the donkey meat, and putting the donkey meat into the soup for cooking to obtain the high-nutrition soy sauce flavor-type marinated donkey meat. The soup is high in nutritional value, the nutritional value of the donkey meat is improved, the two sides of the donkey meat can be punched, manual punching of the donkey meat is not needed, the labor intensity is reduced, the production efficiency of the high-nutrition soy sauce flavor-type marinated donkey meat is improved, and the donkey meat can be completely tasty.

Owner:ANHUI CHUNFENG FOOD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com