Mold release agent and preparation method and application thereof

A mold release agent and solvent technology, applied in the field of mold release agent, can solve the problems of blurred mold details, increased production cost and environmental protection pressure, mold damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

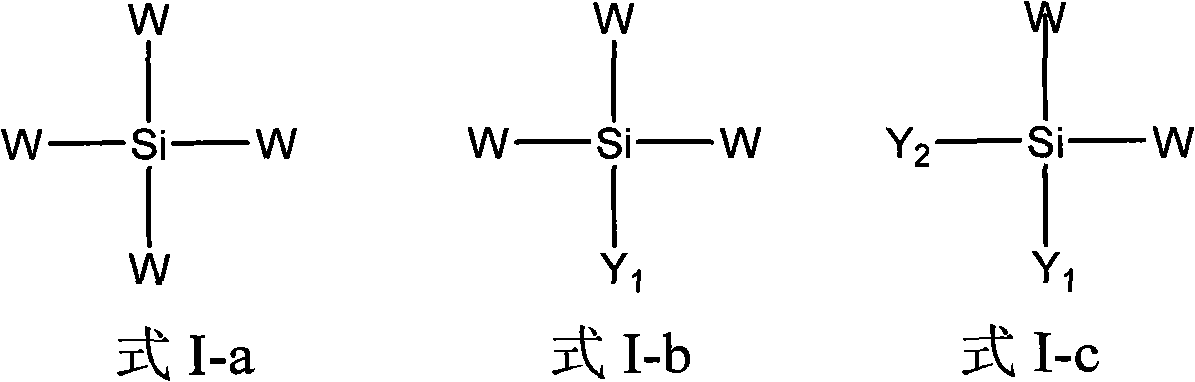

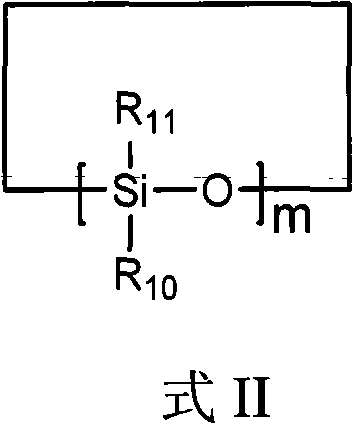

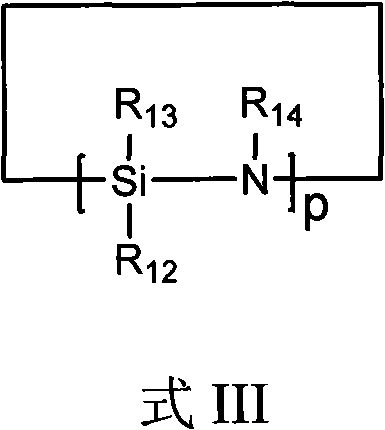

Method used

Image

Examples

Embodiment 1

[0078] Add the ingredients and dosage listed in Table 1 into the dispersion tank at a temperature of 20° C. and stir at 100 rpm for 5 minutes to obtain the mold release agent of the present invention.

[0079] Table 1

[0080]

Embodiment 2

[0082] Add the ingredients and dosage listed in Table 2 into the dispersion tank. In the dispersion tank, stir at 200 rpm for 6 minutes at a temperature of 25° C. to obtain the release agent of the present invention.

[0083] Table 2

[0084]

Embodiment 3

[0086] Add the ingredients and dosage listed in Table 3 into the dispersion tank. In the dispersion tank, stir at 250 rpm for 7 minutes at a temperature of 30° C. to obtain the release agent of the present invention.

[0087] table 3

[0088] Reality

[0089]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com