Microwave foaming device for melamine resin

A technology of microwave foaming and melamine resin, which is applied in the directions of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc. High tear strength, not easy to drop powder, low brittleness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

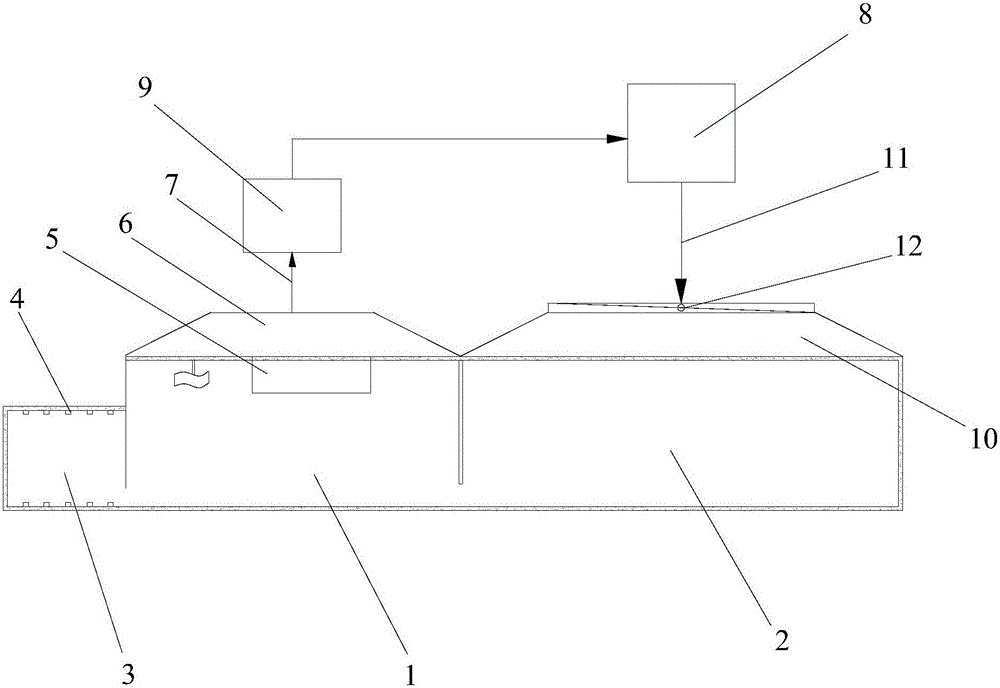

[0021] Such as figure 1 As shown, this embodiment provides a microwave foaming device for melamine resin, which includes a microwave cavity 1 and a drying and curing cavity 2 in sequence according to the material conveying direction, and a pre-foaming microwave cavity 3 is arranged in front of the microwave cavity 1 , two rows of small microwave sources 4 are respectively arranged on the top wall and the bottom wall of the pre-firing microwave cavity, and each row has five small microwave sources 4, and the power of each small microwave source 4 is 1kW. A microwave source 5 with a power of 20kW is arranged on the wall. The production device pre-foams the cavity before the microwave cavity 1, and then foams, which effectively avoids the problem of uneven foam density caused by the uneven radiation of the melamine resin during the foaming process. Moreover, a plurality of microwave sources are evenly arranged in the pre-foaming microwave cavity 3, which can make the microwave r...

Embodiment 2

[0026] Such as figure 1 As mentioned above, this embodiment provides a microwave foaming device for melamine resin. In this embodiment, the microwave frequency of the pre-foaming microwave cavity 3 is 915 MHz, which is the same as the microwave frequency of the microwave source in the microwave generating cavity. Therefore, The device does not require a microwave backstop.

[0027] Other structures of this embodiment are the same as those of Embodiment 1, and will not be repeated here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com