Single-point supporting film rolling mill capable of displaying roller gap

A roll gap and roll technology, which is applied in the field of single-point support film rolling machines, can solve the problems of uneven thickness, inconsistent roll gap at both ends, and unsynchronized movement of support cylinders.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

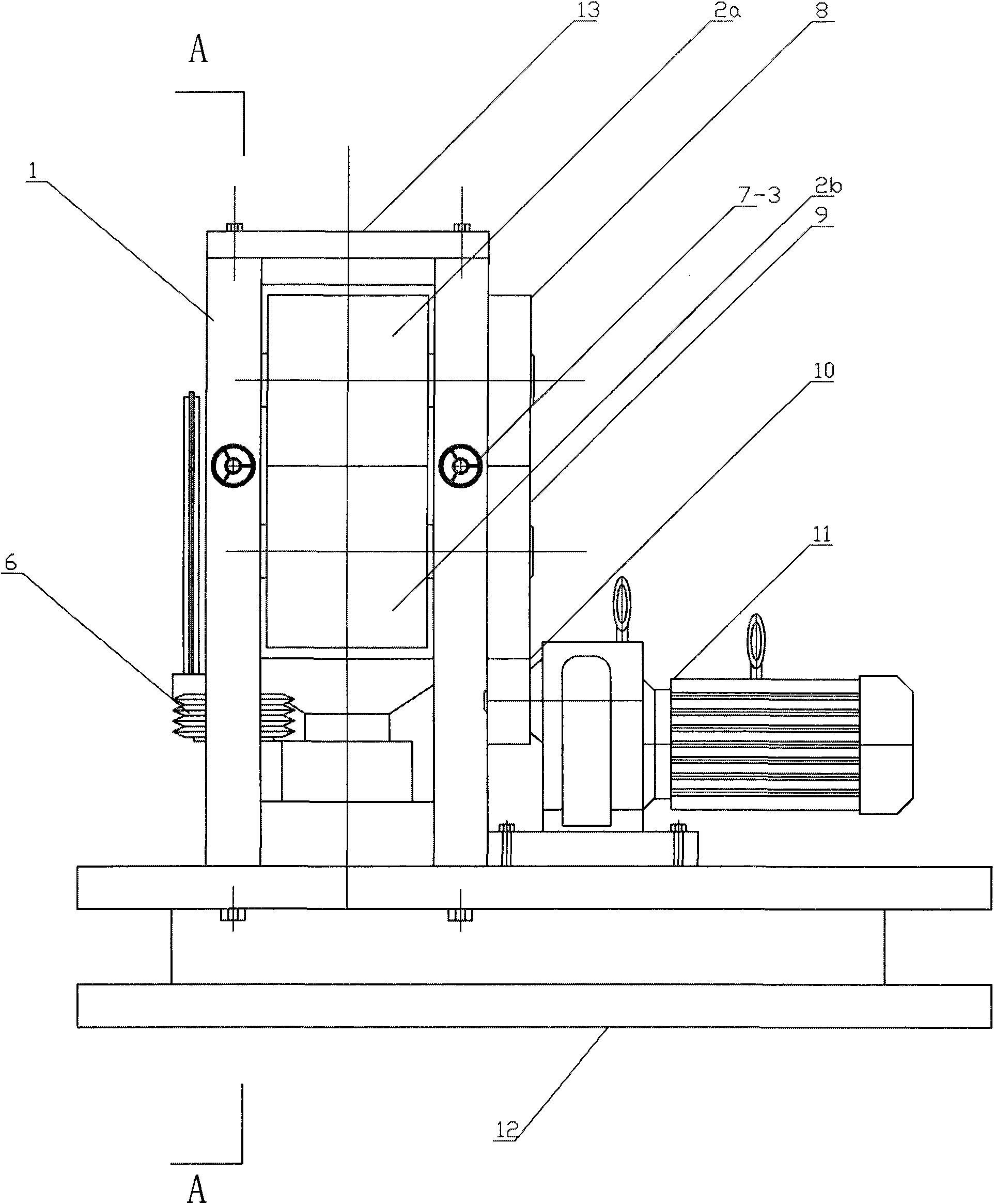

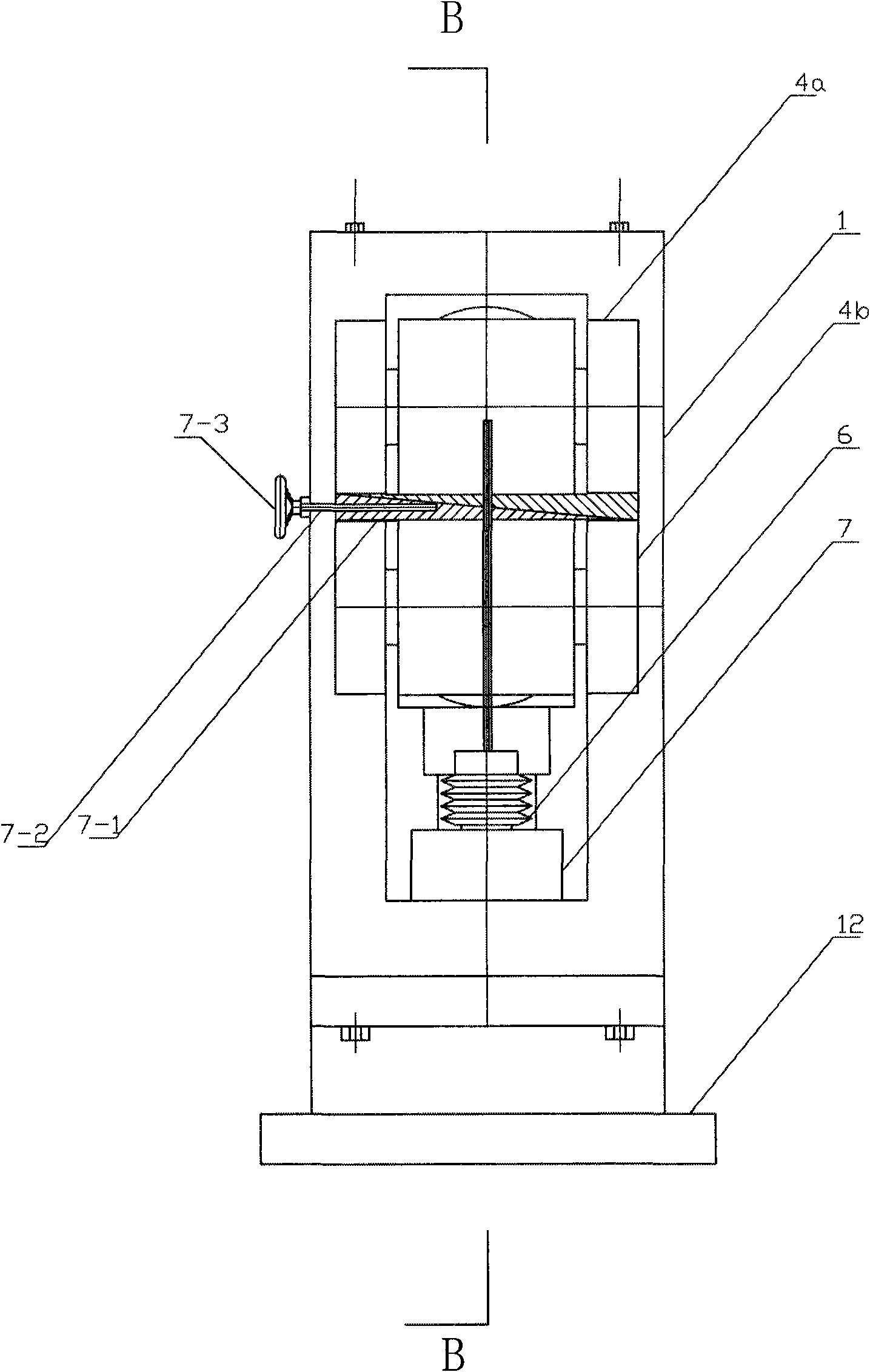

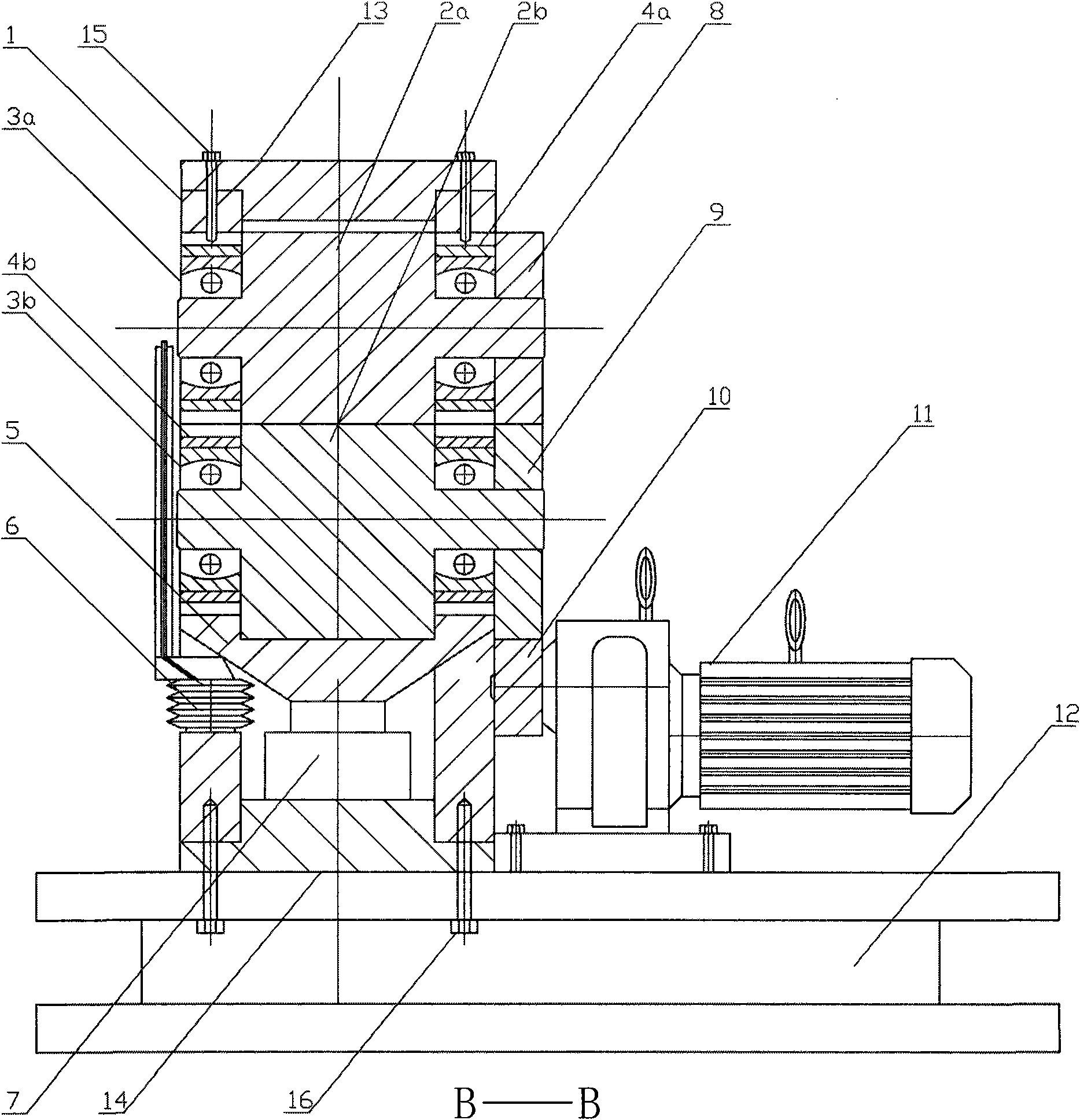

[0027] refer to image 3 : Two frame supports 1 are installed facing each other, connected by upper seat beam 13 and lower seat beam 14, fixed by bolts 15 and bottom bolts 16, bearing 3a is installed at both ends of upper roller 2a, bearing 3a is installed with bearing seat 4a, and bearing seat 4a is fixed Installed on two frame supports 1;

[0028] The two ends of the lower roller 2b are installed with bearings 3b, and the bearings 3b are installed with bearing housings 4b. The bearing housings 4b are fixed on the two ends of the inverted edge support 5, and the center of the lower edge of the inverted edge bearing 5 is fixed on the oil cylinder 7, inverted. The two ends of the type prism support 5 are wedged into the frame support 1, so that the movement in the horizontal direction is limited, and the vertical direction can be slid up and down. The driven gear pair 8 is installed on the end of the upper roll 2a, and the driven gear 9 is installed on the lower roll 2b. At th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com