Body Interior Auxiliary Devices

A technology for auxiliary devices and car bodies, applied in electrolytic coatings, electrophoretic plating, coatings, etc., can solve the problems of substandard and high electrophoretic film thickness inside large car bodies, and the unqualified rate of electrophoretic paint film thickness, so as to reduce scrap. and rework phenomenon, good uniformity, overcoming the effect of uneven film thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

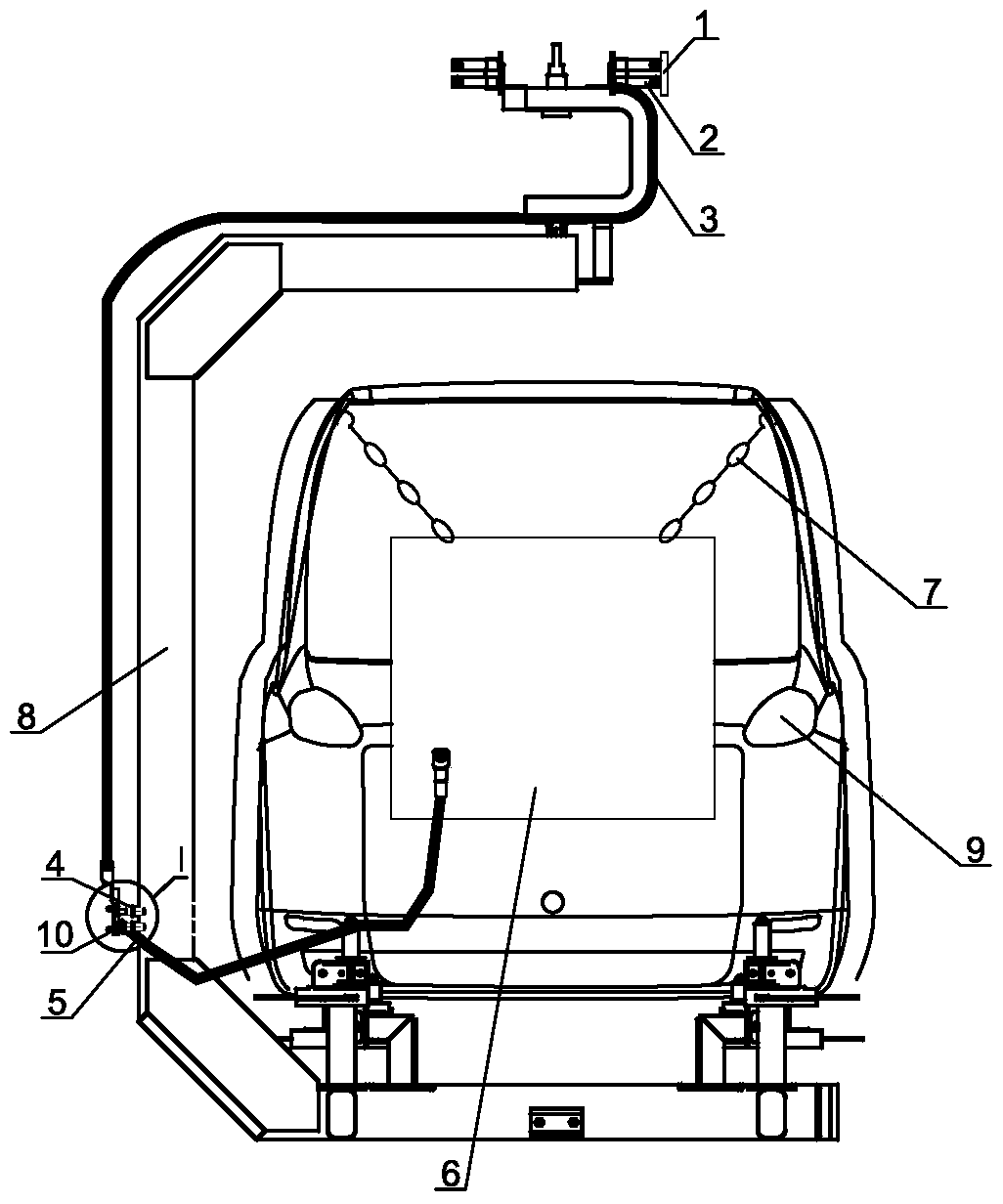

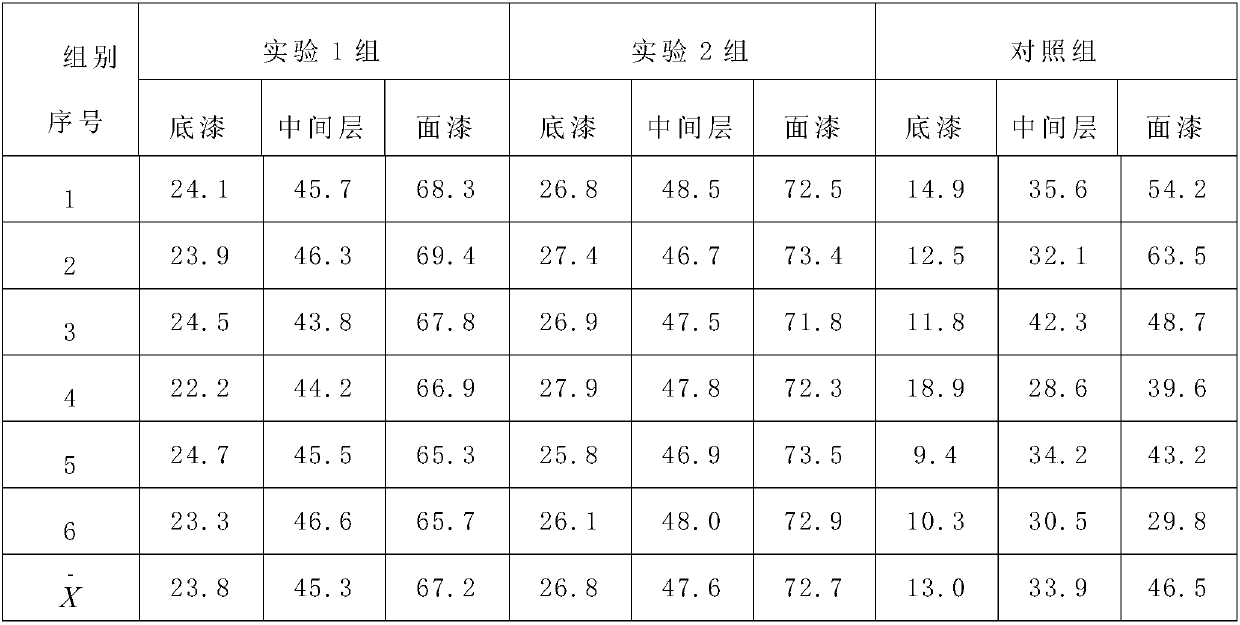

[0031] Embodiment 1 A vehicle body interior auxiliary device

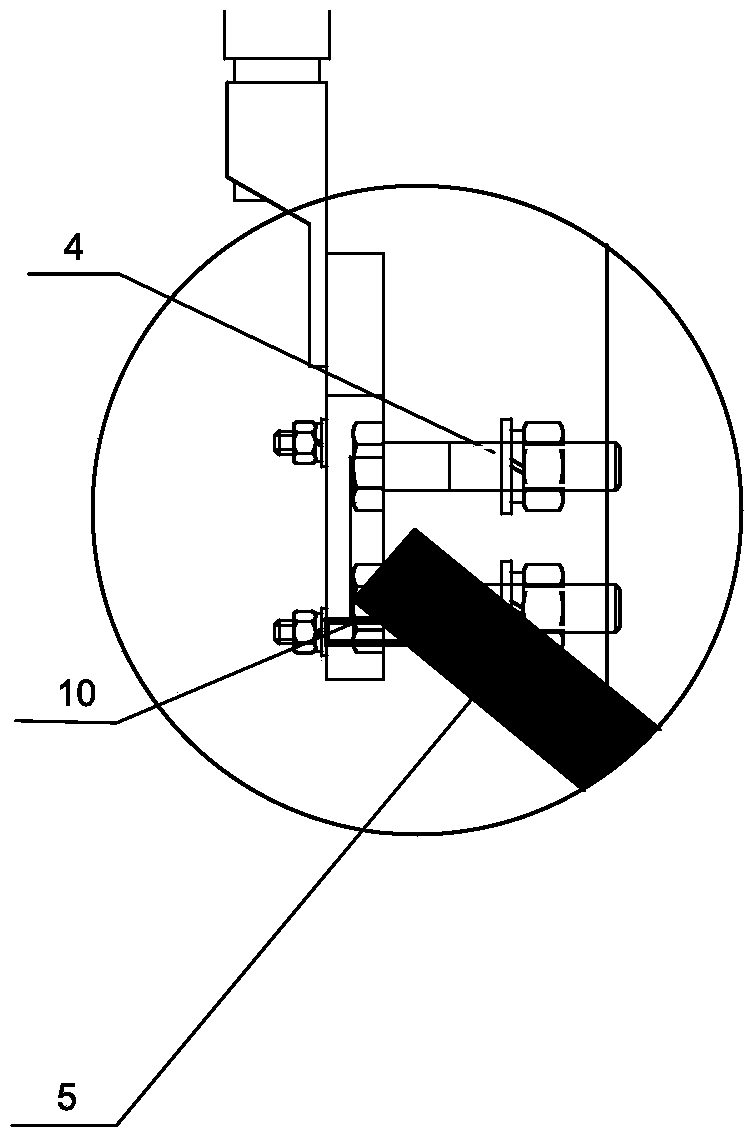

[0032] A body interior auxiliary device such as figure 1 As shown, the auxiliary device includes an electrophoresis tank, a conductive copper bar 1, a brush 1, a cable 3 with an insulating layer, a connecting seat 4, a high temperature cable 5, an auxiliary anode plate 6, a car body hanger 8 and a car body 9; The conductive copper bar 1 is fixed on the side of the electrophoresis tank and is insulated and connected with the electrophoresis tank; the conductive copper bar 1 is connected to the brush 2; the brush 2 connected in sequence, the cable 3 with an insulating layer and the connecting seat 4 are fixed and installed On the car body spreader 8, and run together with the car body spreader 8; the high temperature cable 5 is fixedly connected with the auxiliary anode plate 6, and connected with the connecting seat 4 through the quick-plug connector 10 of the connector; the auxiliary anode plate 6 passes through T...

Embodiment 2

[0033] Embodiment 2 A painting method using the auxiliary device inside the vehicle body of Embodiment 1

[0034] The method comprises the steps of:

[0035] 1) Connect the conductive copper bar 1 to the brush 2, and fix the sequentially connected brush 2, the cable 3 with an insulating layer and the connecting seat 4 on the car body hanger 8; then fix the high-temperature cable 5 Installed on the auxiliary anode plate 6, and then connected with the connection seat 4 fixed on the car body hanger 8 through the quick plug joint 10; the auxiliary anode plate 6 is suspended inside the vehicle body 9 through the hook chain 7, and the hook chain 7 is insulated and connected with the body 9;

[0036] 2) Coating the body: including high-pressure cleaning, degreasing, passivation, water washing, first drying, spraying, second drying and grinding;

[0037] 3) While the body is being painted, the body 9 and the auxiliary anode plate 6 are energized; the auxiliary anode plate 6 is posit...

Embodiment 3

[0038] Embodiment 3 A painting method using the auxiliary device inside the vehicle body in Embodiment 1

[0039] The method comprises the steps of:

[0040] 1) Connect the conductive copper bar 1 to the brush 2, and fix the sequentially connected brush 2, the cable 3 with an insulating layer and the connecting seat 4 on the car body hanger 8; then fix the high-temperature cable 5 Installed on the auxiliary anode plate 6, and then connected with the connection seat 4 fixed on the car body hanger 8 through the quick plug joint 10; the auxiliary anode plate 6 is suspended inside the vehicle body 9 through the hook chain 7, and the hook chain 7 is insulated and connected with the body 9;

[0041] 2) Paint the body, including:

[0042] High-pressure cleaning, the pressure of the high-pressure cleaning step is 0.43MPa;

[0043] Degreasing, the degreasing step uses a degreasing agent for degreasing, and the high degreasing agent is composed of the following components by weight: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com