Dried tofu pulp adding machine

A technology of drying tofu and splashing slurry, which is applied in the field of soybean product processing equipment, can solve the problems of high product cost, increased rack height, and inconvenient operation, and achieve the effects of increasing output rate, ensuring cleanliness and sanitation, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The concrete technical scheme of the present invention will be further described below in conjunction with embodiment:

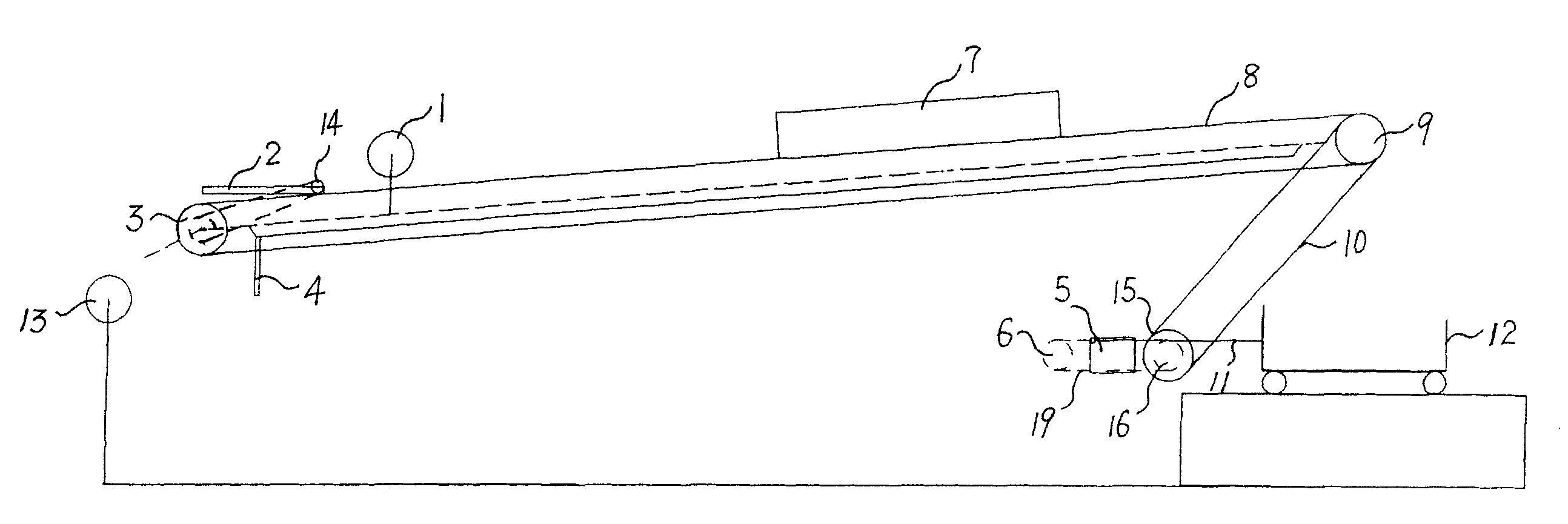

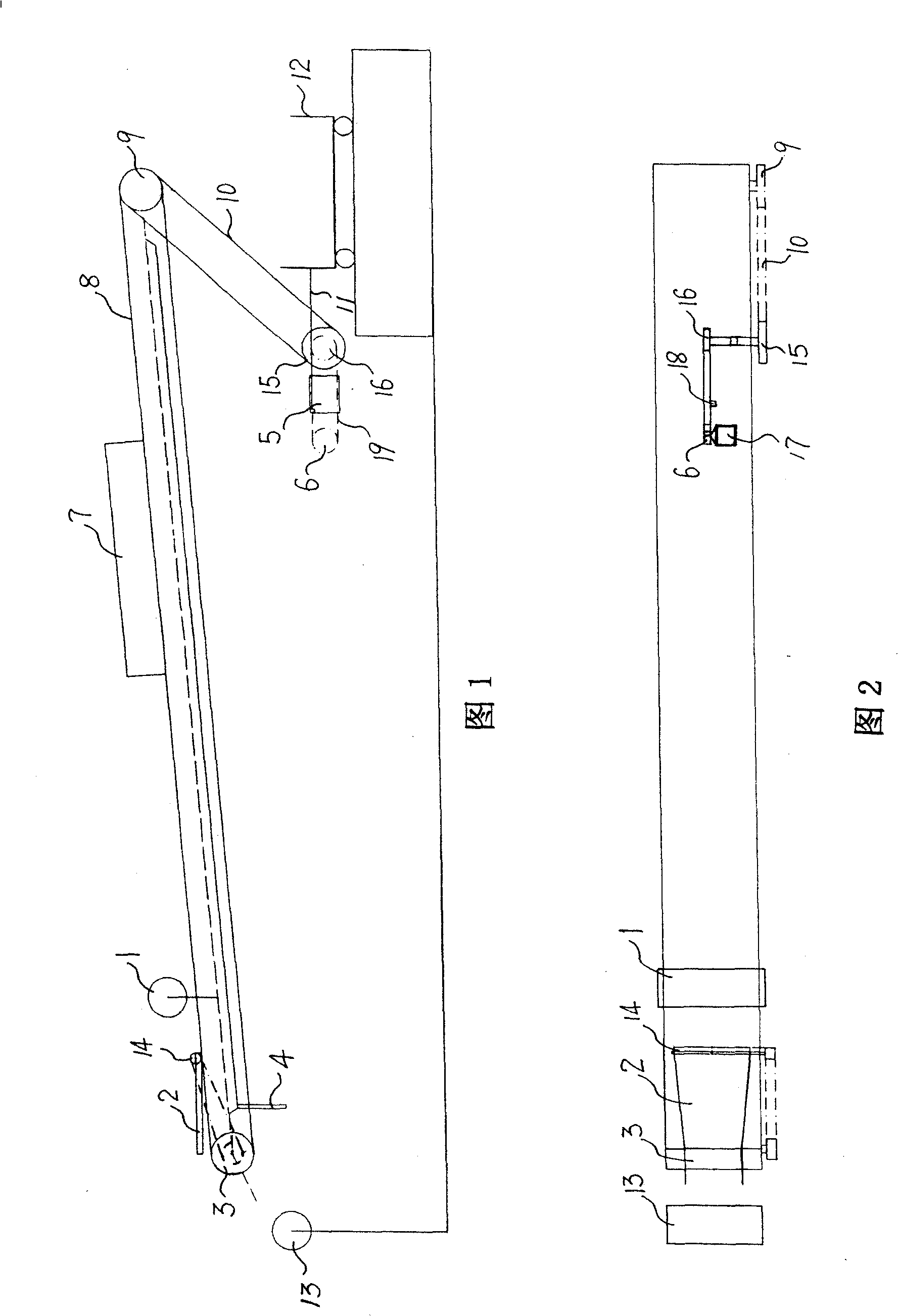

[0020] As shown in Figures 1 to 2, this dry bean curd slurry splashing machine includes an upper cloth support frame 1, a lower cloth support frame 13, a cloth pinch 2, a conveyor belt 8 and a transmission device, wherein the lower cloth support frame 13 Set on one side of the pulley 3 at the head of the conveyor belt 8, the upper cloth support frame 1 is arranged on the front part of the conveyor belt 8, on the conveyor belt 8 between the upper cloth support frame 1 and the lower cloth support frame 13 A cloth pinch 2 is provided, the rear end of the cloth pinch 2 is provided with a limiting pressure roller 14, a heating box 7 is provided above the middle rear part of the conveyor belt 8, and a water collection tank 4 is provided below the conveyor belt 8, The conveyor belt tail pulley 9 in the transmission device is connected with the conveyor belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com