Ultrathin mortar joint masonry construction method of sintered shale insulation hollow block pulp bonding method

A technology of hollow blocks and construction methods, which is applied in the field of building wall materials, can solve problems such as thick mortar joints in walls, and achieve the effects of eliminating thermal bridges, improving bearing capacity, and weakening complex stress effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

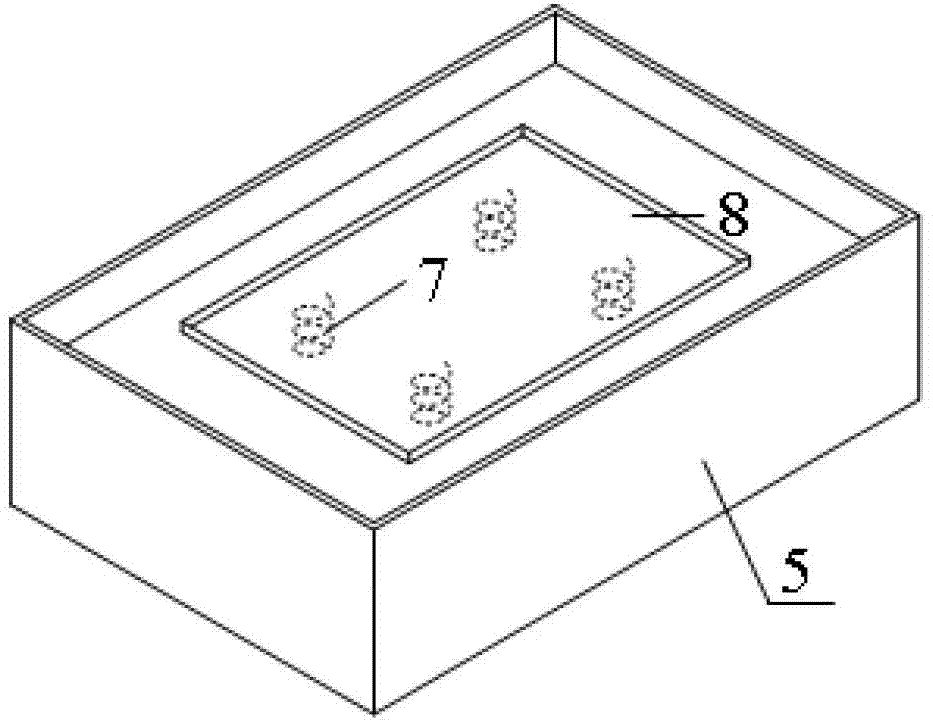

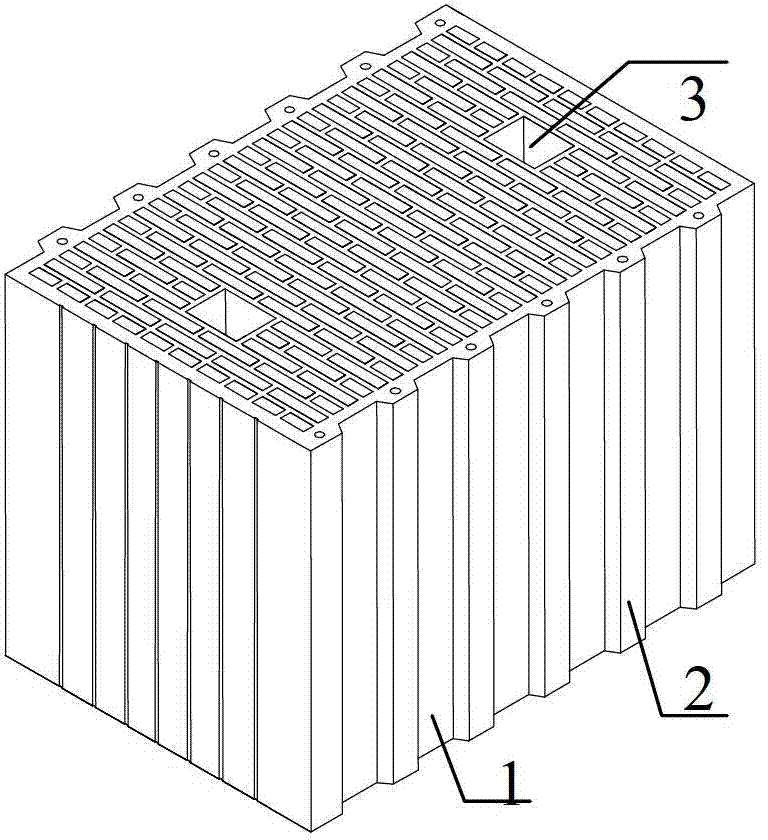

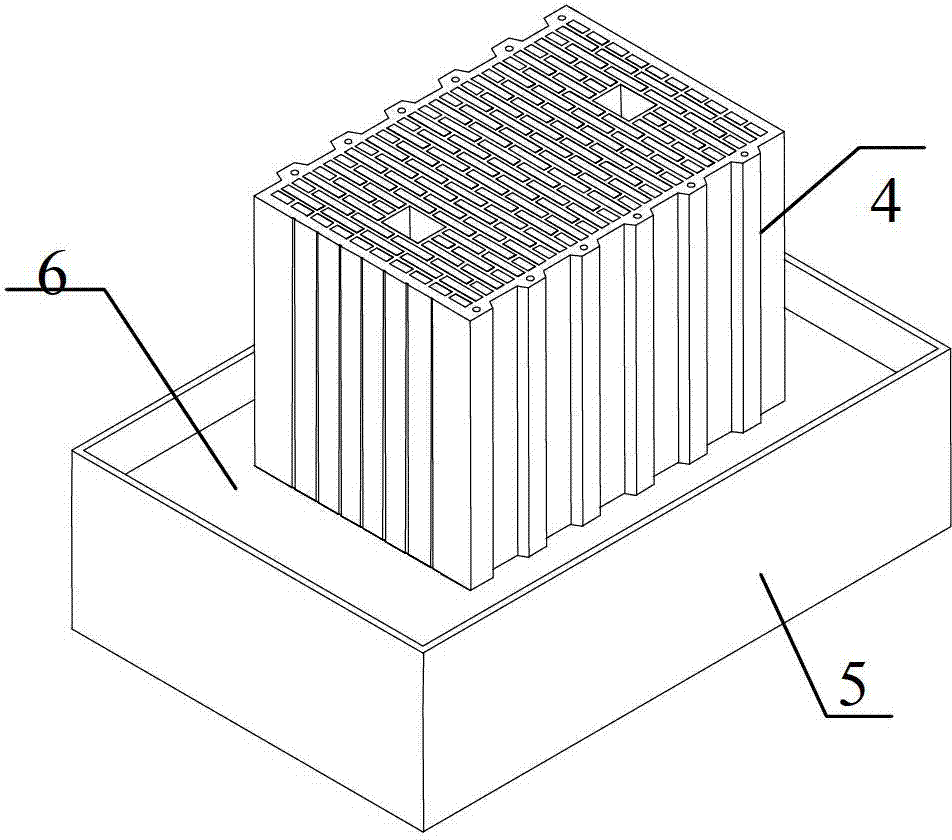

[0028] Such as Figure 1-Figure 4 As shown, the sintered shale thermal insulation hollow block of the present invention is sticky mortar thin gray joint masonry construction method, and its specific steps are:

[0029] Step 1. Base surface cleaning and leveling: Clean up the base surface to be built and remove the protruding parts; level the base surface with ordinary mortar, and check the flatness with a level.

[0030] Step 2. Laying out: According to the design drawings, determine the edge of the wall, the openings of doors and windows, and the position lines of structural columns, and control the deviation within the allowable range.

[0031] Step 3, erect the number rods: erect the number rods uniformly with a level, so that the elevations on each number rod match, and check the thickness of the skin on the number rods against the design drawing; Elevation position.

[0032] Step 4, block preparation: such as figure 2 As shown, block 4 is made of sintered shale therma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com