Cooling structure of solid-wall pipe extrusion die head

A technology of cooling structure and solid wall tube, applied in the field of plastic molding, can solve problems such as melt heat insulation, and achieve the effects of enhancing manufacturing accuracy, reducing cost and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

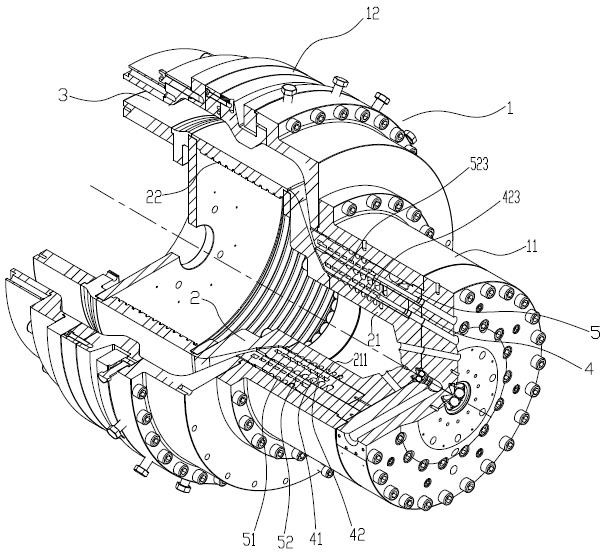

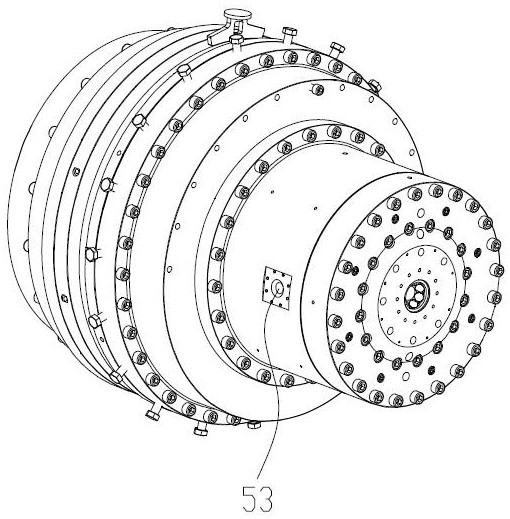

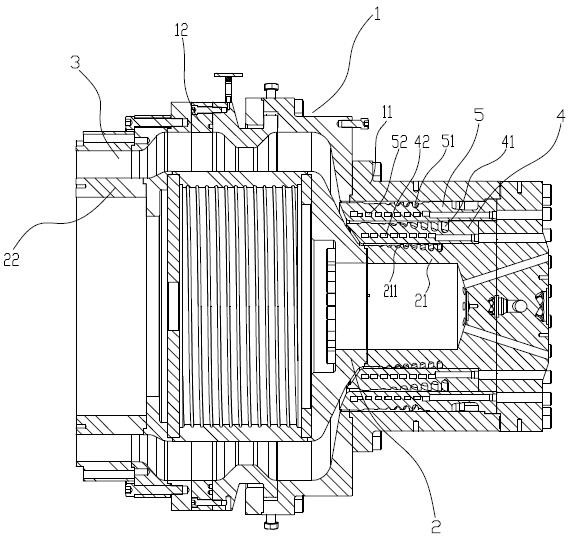

[0027] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. It should be noted here that the descriptions of these embodiments are used to help understand the present invention, but are not intended to limit the present invention. In addition, the technical features involved in the various embodiments of the present invention described below may be combined with each other as long as they do not constitute a conflict with each other.

[0028] See attached Figure 1-4 As shown, the cooling structure of a solid-wall pipe extrusion die head in this embodiment includes a die sleeve 1 and a mold core 2 located inside the die sleeve 1. The die sleeve 1 includes a front die sleeve 11 and a tail die sleeve 12. The die core 2. It includes the main mandrel 21 and the tail die core 22. An annular cavity 3 for material flow is formed between the tail die sleeve 12 and the tail die core 22. There are two sleeves b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com