Novel perforated film processing machine

A processing machine and film technology, which is applied in the field of new porous film processing machines, can solve the problems of difficult automatic processing, low processing efficiency, poor toughness, etc., and achieve the effects of high processing efficiency, uniform opening, and no burr in opening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to further understand the content of the invention, features and effects of the present invention, the following examples are given in detail as follows:

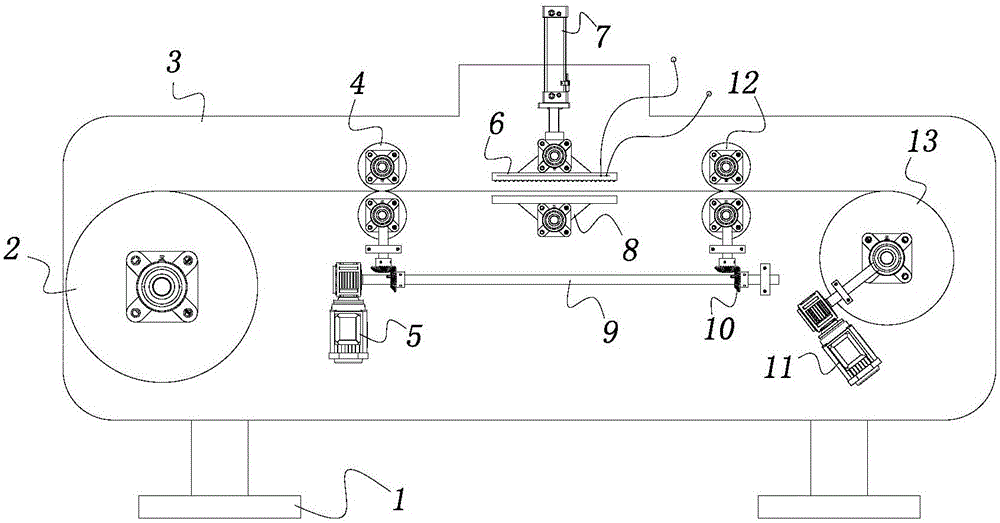

[0013] See figure 1 , the new perforated film processing machine of the present invention comprises two oppositely arranged side plates 3 supported by a column 1, an unwinding shaft 2 is arranged between the head ends of the two side plates 3, and a winding shaft is arranged between the tail ends 13.

[0014] Both the unwinding shaft 2 and the winding shaft 13 have a three-section structure, the sections at both ends are installed on the shaft seats on the two side plates 3, and the section in the middle is detachably fixed between the other two sections . The three-stage structure of the unwinding shaft 2 and the winding shaft 13 facilitates loading and unloading of the rolled film reel to the unwinding shaft 2 and the winding shaft 13 .

[0015] A winding motor 11 that drives the winding shaft 13 is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com