Throttle driving device

A driving device and damper technology, applied in transportation and packaging, railway car body parts, railway vehicle heating/cooling, etc., can solve problems such as uneven airflow, high processing cost, and large resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Taking the application of the damper driving device of the present invention on the split leaf damper as an example below, the embodiments of the present invention will be described in detail in conjunction with the accompanying drawings. The operation process, but the scope of protection of the present invention is not limited to the following examples.

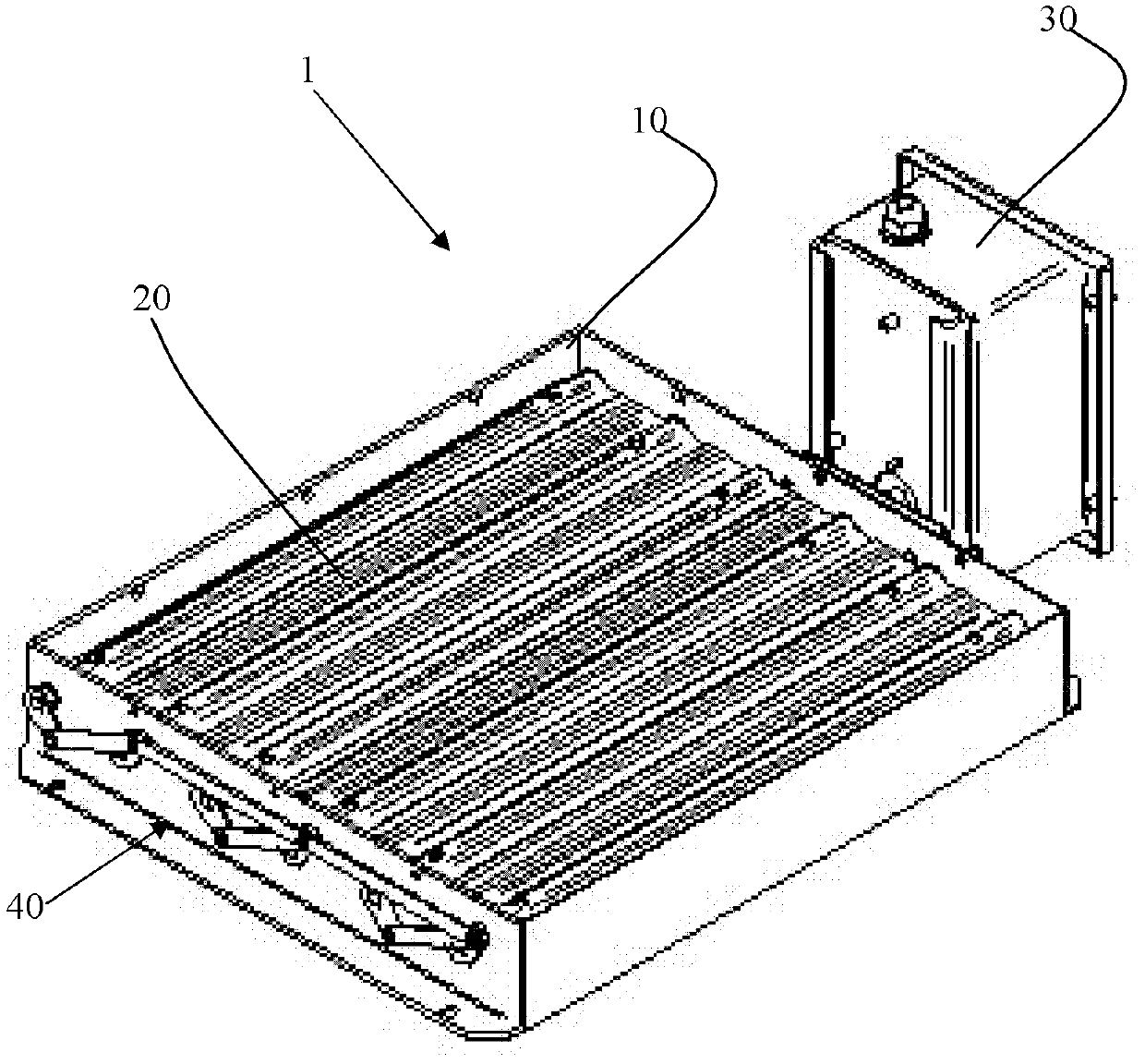

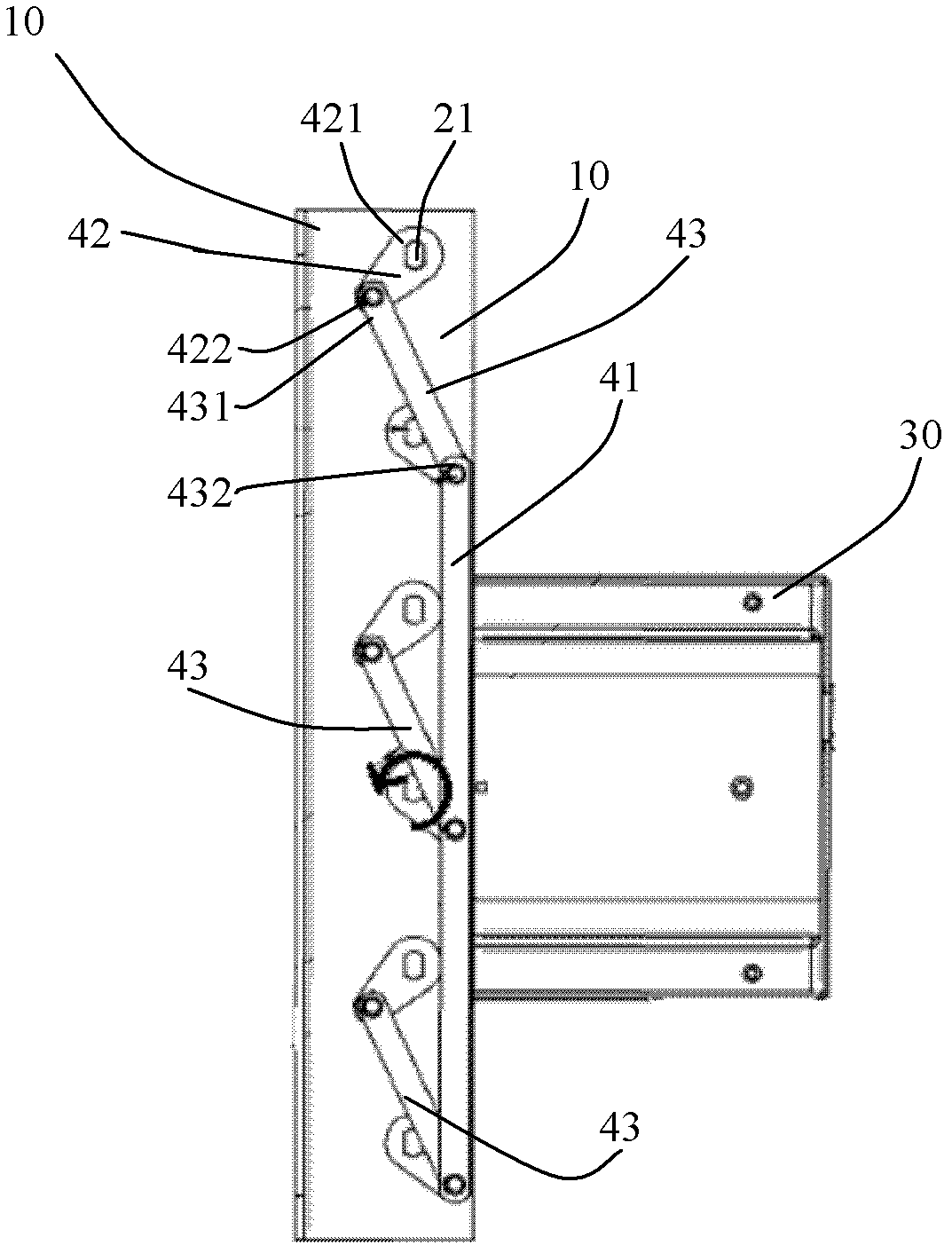

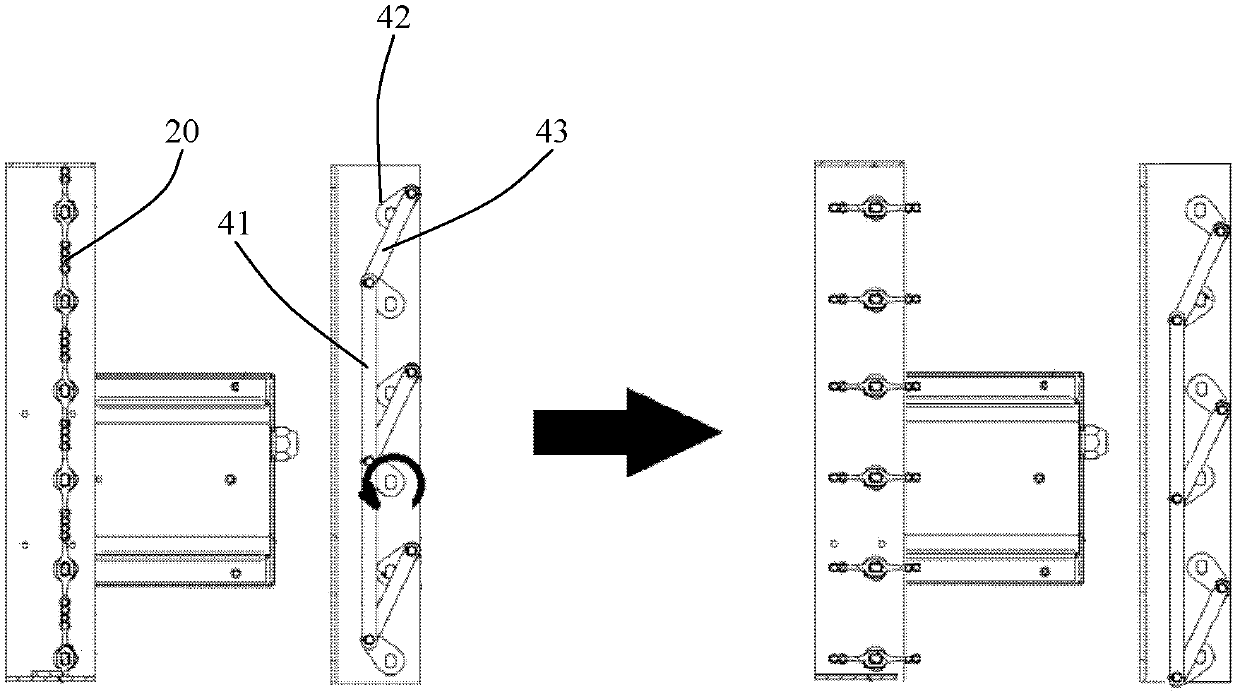

[0011] refer to Figure 1~2 As shown, the split leaf damper 1 applying the damper driving device of the present invention includes a housing 10, a plurality of blades 20 and a motor 30, and each blade 20 passes through a drive shaft 21 (that is, a power input shaft and a power output shaft) to The rotatable opening and closing mode is arranged on the inner side of the housing 10, and the motor 30 drives the blade 20 through the damper driving device 40 of the present invention to realize opening and closing, wherein the damper driving device 40 is mainly composed of a main connecting rod 41, a plurality of rotating bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com