Slickens baked brick and production method thereof

A technology of sintered bricks and stone mud, which is applied in the field of sintered bricks, which can solve the problems of difficult sintering, cracking or bursting, and failure to achieve industrialization, and achieve the effects of not being easy to burst, protecting cultivated land, and saving land resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The raw material of stone mud sintered bricks, calculated by absolute dry weight, includes the following components in parts by weight:

[0040] 40 parts by weight of stone mud;

[0041] 35 parts by weight of coal gangue;

[0042] 15 parts by weight of engineering slag;

[0043] 8 parts by weight of clinker;

[0044] Fine sawdust 8 parts by weight.

[0045] The above-mentioned coal gangue and clinker are powders with a particle size of 0.1-0.2 mm.

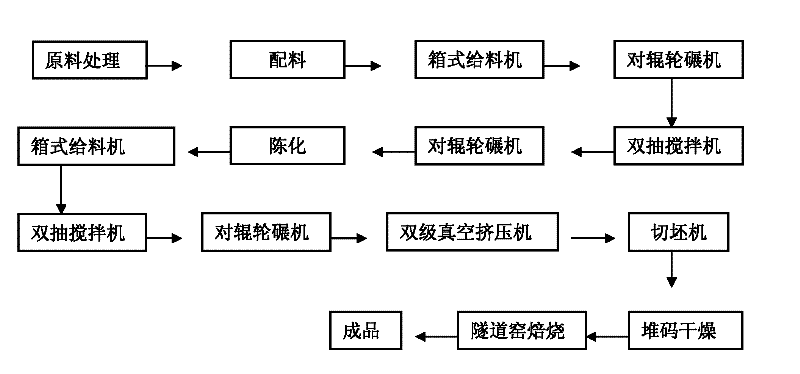

[0046] The preparation method of stone mud sintered brick (such as figure 1 Shown process flow chart) is:

[0047] Dry and dehydrate the mud with a water content of 30% sawn during marble processing to a water content of 13-18%; grind coal gangue and clinker to a particle size of 0.1-0.2mm; 20-21% of the river course expenditures are dried to a moisture content of 13-18%; the fine wood chips are crushed to a particle size of 1-2mm; coal gangue, engineering slag, clinker and Fine wood chips are added into the stone mud...

Embodiment 2

[0052] The raw material of stone mud sintered bricks, calculated by absolute dry weight, includes the following components in parts by weight:

[0053] 45 parts by weight of stone mud;

[0054] 30 parts by weight of cinder;

[0055] 25 parts by weight of shale;

[0056] 10 parts by weight of clinker;

[0057] 8 parts by weight of chaff.

[0058] The cinder, shale and clinker mentioned above are powders, and the particle diameters are all 0.1-3mm.

[0059] The preparation method of stone mud sintered brick is as follows:

[0060] Dry and dehydrate the mud with a water content of 40% sawn during marble processing to a water content of 13-18%; grind cinder, shale and clinker to a particle size of 0.1-3mm; grind the chaff Grinding to a particle size of 1-2mm; adding cinders, shale, clinker and chaff into the mud according to the proportion, adding water to adjust the moisture content of the mixture to 13-16%, and aging for 6-7 days. After aging, it is fully stirred, rolled and...

Embodiment 3

[0064] The raw material of stone mud sintered bricks, calculated by absolute dry weight, includes the following components in parts by weight:

[0065] Stone mud 35 parts by weight;

[0066] 35 parts by weight of coal gangue;

[0067] 10 parts by weight of engineering slag;

[0068] 5 parts by weight of clinker;

[0069] Fine sawdust 3 parts by weight.

[0070] The above-mentioned coal gangue and clinker are powders with a particle size of 0.1-0.5 mm.

[0071] The preparation method of stone mud sintered brick is as follows:

[0072] Dry and dehydrate the mud with a water content of 40% sawed during the marble processing process to a water content of 13-18%; grind the coal gangue and clinker to a particle size of 0.1-0.3mm; crush the fine wood chips to a particle size of 1-2mm; add water to the underground engineering dregs obtained from tunnel excavation with a moisture content of 8% to a moisture content of 13-18%; mix coal gangue, engineering dregs, clinker and fine wo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com