Plating assisting agent for batch hot-dip coating of Galfan and preparation method of plating assisting agent

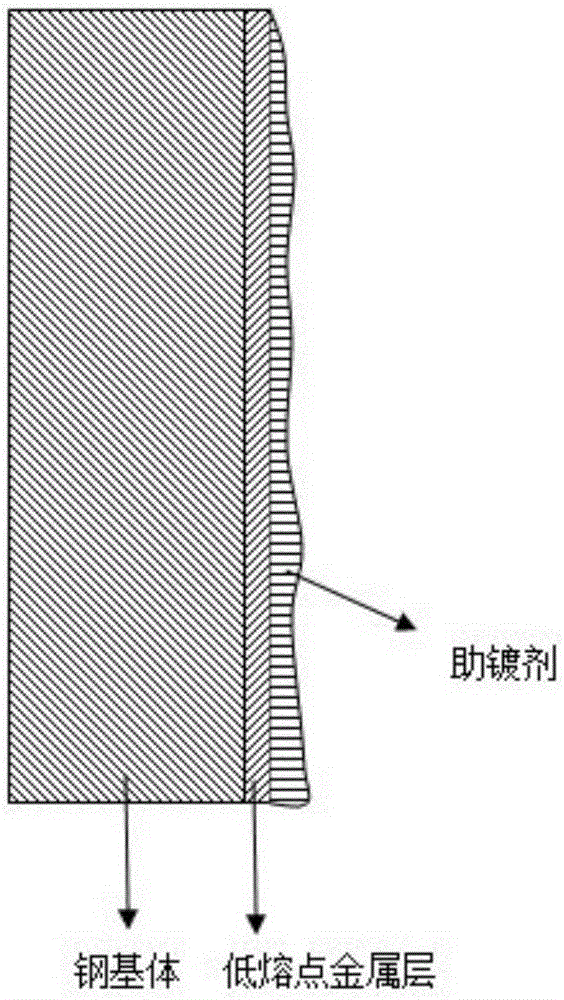

A kind of flux, hot-dip technology, applied in hot-dip plating process, coating, metal material coating process, etc., can solve the problems of dark coating surface, difficult surface infiltration, leakage plating, etc., to promote the replacement reaction, volume The effect of small and large affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] The formula that the flux of present embodiment batch hot-plating Galfan calculates with every liter of flux is:

[0067] Zinc chloride 150g,

[0068] The alkali metal chloride is sodium chloride, 20g,

[0069] Bismuth chloride or / and tin chloride is tin chloride, 20g,

[0070] Transition metal element chloride is nickel chloride, 5g,

[0071] Calcium chloride 10g,

[0072] The rare earth chloride is cerium chloride, 2g,

[0073] Industrial hydrochloric acid 25ml, the concentration of industrial hydrochloric acid is 32wt%.

[0074] The rest is water.

[0075] The preparation method of present embodiment plating flux is:

[0076] (1) According to the above formula, the ingredients are taken by weighing, and the industrial hydrochloric acid taken is divided into 5 parts on average, each part of 5ml;

[0077] (2) Dissolve zinc chloride in water, stir while dissolving, add 15ml of industrial hydrochloric acid after stirring evenly, mark it as liquid A;

[0078] (3) ...

Embodiment 2

[0084] The formula that the flux of present embodiment batch hot-plating Galfan calculates with every liter of flux is:

[0085] Zinc chloride 100g,

[0086] The alkali metal chloride is potassium chloride, 10g,

[0087] Bismuth chloride or / and tin chloride is bismuth chloride, 10g,

[0088] Transition metal element chloride is vanadium chloride, 2g,

[0089] Calcium chloride 5g

[0090] The rare earth chloride is lanthanum chloride, 1g,

[0091] Industrial hydrochloric acid 20ml, the concentration of industrial hydrochloric acid is 32wt%.

[0092] The rest is water.

[0093] The preparation method of the plating flux of this embodiment is the same as that of Embodiment 1.

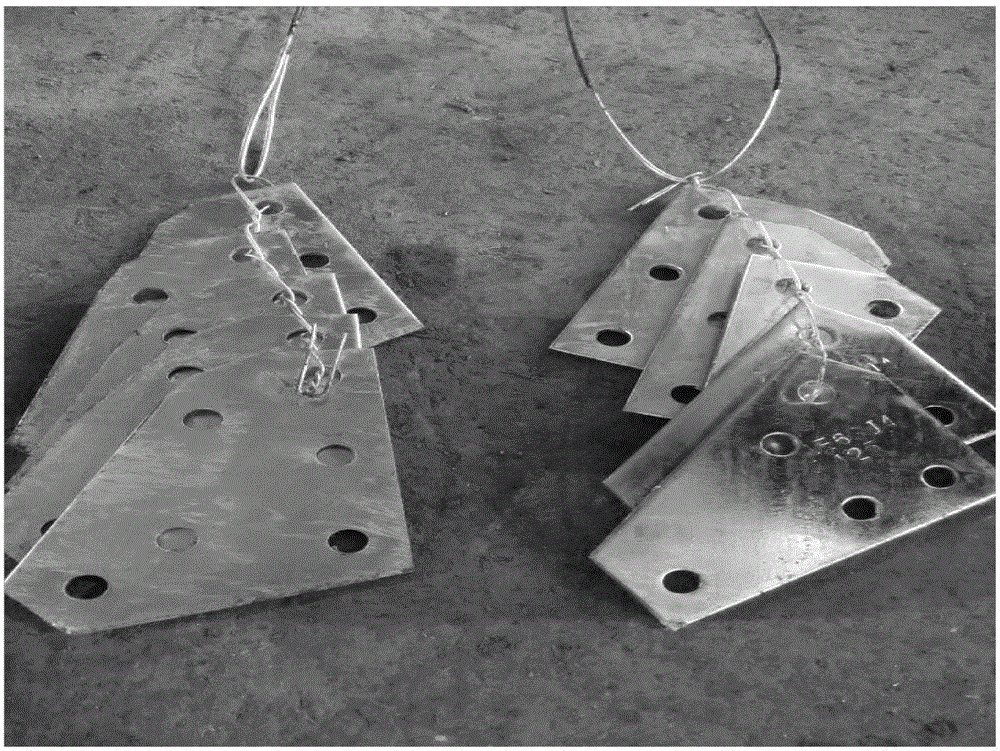

[0094] Take the Si-containing steel structure, then degrease, wash with water, pickle for 5 minutes, and then wash with water for pretreatment.

[0095] Put the plating flux prepared in this example into a water bath and heat it to 60°C, then put the above-mentioned pretreated Si steel structure into ...

Embodiment 3

[0097] The formula that the flux of present embodiment batch hot-plating Galfan calculates with every liter of flux is:

[0098] Zinc chloride 180g,

[0099] The alkali metal chloride is potassium chloride, 15g,

[0100] Bismuth chloride or / and tin chloride is bismuth chloride, 12g,

[0101] Transition metal element chloride is nickel chloride, 2g,

[0102] Calcium chloride 5g

[0103] The rare earth chloride is lanthanum chloride, 1g,

[0104] Industrial hydrochloric acid 20ml, the concentration of industrial hydrochloric acid is 32wt%.

[0105] The rest is water.

[0106] And prepare this plating flux according to the step described in embodiment 1.

[0107] The structural parts in this embodiment are HRB400 rebars (structural steel, continuous hot-dip plating cannot be used) with diameters of 10 mm and 20 mm respectively, and are pretreated by degreasing, washing with water, pickling for 5 minutes, and washing with water again.

[0108] Heat the fluxing agent prepare...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com