Flexible lead frame preparation process capable of avoiding blind hole electroplating

A flexible lead and preparation process technology, applied in printed circuit manufacturing, circuits, printed circuits, etc., can solve the problems of difficult electroplating of pressure-welding holes of flexible lead frames, and achieve the effect of improving electroplating rate, high efficiency, and stable electroplating process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

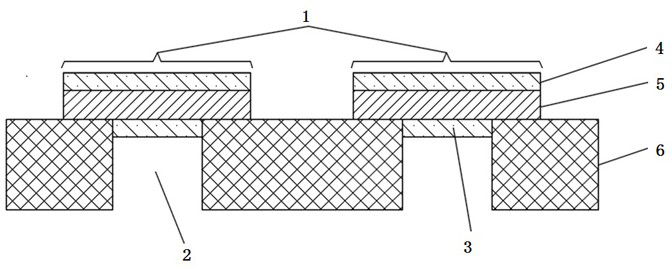

Image

Examples

Embodiment 1

[0048] Adopt technology of the present invention to prepare flexible lead frame, technological process is:

[0049] (1) Conduct electroplating on the back of the conductive metal layer first:

[0050] ① Dry film pressing for the first time: Use lamination equipment to attach photosensitive film on the upper and lower surfaces of the conductive metal layer. The pressing parameters of the photosensitive film are temperature 90°C, pressure 0.1Mpa, and speed 1m / min.

[0051] ②First exposure: Use exposure equipment to expose the position of the non-pressure welding hole on the photosensitive film. The exposure light source is 5000W ultraviolet parallel light, and the exposure light intensity is 10mw / cm 2 , the exposure time is 10s.

[0052] ③The first development: Use a developing device with a spray function, use a weak alkaline chemical solution (sodium carbonate), remove the unexposed photosensitive film, and leak the position corresponding to the welding hole, that is, the pos...

Embodiment 2

[0070] Adopt technology of the present invention to prepare flexible lead frame, technological process is:

[0071] (1) Conduct electroplating on the back of the conductive metal layer first:

[0072] ① Dry film pressing for the first time: Use film pressing equipment to attach photosensitive film on the upper and lower surfaces of the conductive metal layer. The pressing parameters of the photosensitive film are temperature 100°C, pressure 0.3Mpa, and speed 3m / min.

[0073] ②First exposure: Use exposure equipment to expose the position of the non-pressure welding hole on the photosensitive film. The exposure light source is 5000W ultraviolet parallel light, and the exposure light intensity is 30mw / cm 2 , the exposure time is 5s.

[0074] ③The first development: Use a developing device with a spray function, use a weak alkaline chemical solution (sodium carbonate), remove the unexposed photosensitive film, and leak the position corresponding to the welding hole, that is, the ...

Embodiment 3

[0092] Adopt technology of the present invention to prepare flexible lead frame, technological process is:

[0093] (1) Conduct electroplating on the back of the conductive metal layer first:

[0094] ① Dry film pressing for the first time: Use lamination equipment to attach photosensitive film on the upper and lower surfaces of the conductive metal layer. The pressing parameters of the photosensitive film are temperature 110°C, pressure 0.5Mpa, and speed 5m / min.

[0095] ②First exposure: Use exposure equipment to expose the position of the non-pressure welding hole on the photosensitive film. The exposure light source is 5000W ultraviolet parallel light, and the exposure light intensity is 50mw / cm 2 , the exposure time is 1s.

[0096] ③The first development: Use a developing device with a spray function, use a weak alkaline chemical solution (sodium carbonate), remove the unexposed photosensitive film, and leak the position corresponding to the welding hole, that is, the pos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com