Coal gangue brick and preparation method thereof

A technology of coal gangue and pumice, applied in ceramic products, other household appliances, applications, etc., can solve problems such as brick body damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

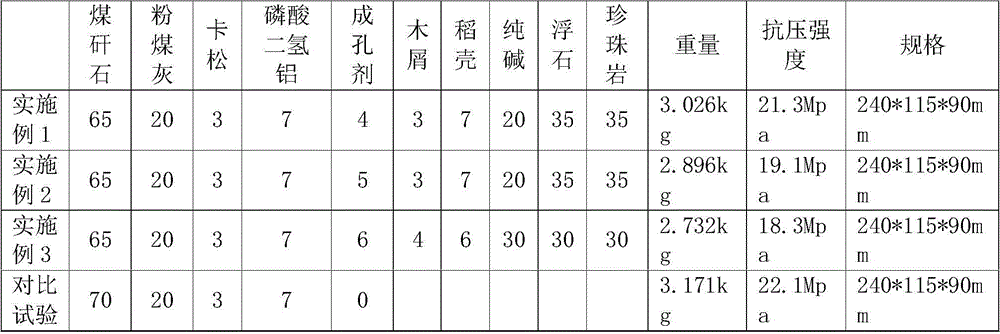

[0022] As shown in the column of Example 1 in Table 1, the coal gangue brick, the scheme is: its components and its preferred mass parts are as follows: 65 parts of coal gangue with a calorific value of 1880kJ / mol, 20 parts of fly ash, Kasong 3 parts, 8 parts of aluminum dihydrogen phosphate, 4 parts of pore-forming agent, pore-forming agent components and their mass parts are as follows, 3 parts of sawdust, 7 parts of rice husk, 20 parts of soda ash, 35 parts of pumice, and 35 parts of perlite.

[0023] The method for preparing coal gangue bricks is as follows:

[0024] (1) Manually detect the calorific value of coal gangue, and batch the coal gangue so that the calorific value of the coal gangue is 1800kJ / mol-2000kJ / mol,

[0025] (2) Remove scrap iron after mixing coal gangue, fly ash, Kasong and aluminum dihydrogen phosphate,

[0026] (3) Coarsely crushing and pulverizing the mixed mixture, and finally ball mill grinding until the maximum particle size is less than 1 mm, ...

Embodiment 2

[0034] The difference from Example 1 is that its components and their preferred mass parts are as follows: 65 parts of coal gangue with a calorific value of 1880kJ / mol, 20 parts of fly ash, 3 parts of Kason, 7 parts of aluminum dihydrogen phosphate, 5 parts of pore-forming agent, pore-forming agent components and their mass parts are as follows: 3 parts of sawdust, 7 parts of rice husk, 20 parts of soda ash, 35 parts of pumice, and 35 parts of perlite. In Example 2, by increasing the mass fraction of the pore-forming agent, while reducing the weight of the brick body, the compressive strength of the brick body is still guaranteed to be 19.1Mpa, which is greater than the strength grades MU10 and MU15 in GB13544-2011.

Embodiment 3

[0036] The difference from Example 2 is that its components and their preferred mass parts are as follows: 64 parts of coal gangue with a calorific value of 1880kJ / mol, 20 parts of fly ash, 3 parts of Kason, 7 parts of aluminum dihydrogen phosphate, 6 parts of pore-forming agent, pore-forming agent components and their mass parts are as follows: 4 parts of sawdust, 6 parts of rice husk, 30 parts of soda ash, 30 parts of pumice, and 30 parts of perlite. In embodiment 3, by increasing the mass fraction of the pore-forming agent, and increasing the mass fraction of soda ash in the pore-forming agent, the weight of the brick body is further reduced, and the compressive strength of the brick body is guaranteed to be 18.3Mpa. It is greater than the strength grades MU10 and MU15 in GB13544-2011.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com