Atomizer capable with nozzle and flow guide tube prevented from blockage

A technology of diversion tube and atomizer, which is applied in the field of atomizer, and can solve the problem of airflow atomization nozzle and diversion tube blocking the atomization process, affecting the atomized powder to achieve the ideal crushing effect, nozzle outlet and atomization point Long distance and other problems, to achieve the effect of eliminating low melting point blockage, reducing component pollution, and maintaining temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

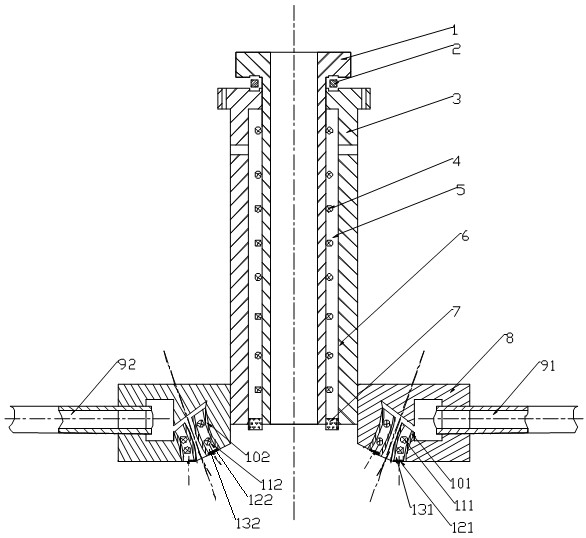

[0040] An atomizer that prevents nozzles and guide tubes from being clogged, its structural schematic diagram is shown in figure 1As shown, it consists of a guide tube 1, a nozzle 8, and also includes a metal jacket 3, a gap 5 between the guide tube 1 and the metal jacket 3, a heating element A4, a white reflective coating 6, a ceramic sealing ring 7, and a heating element B111 and B112, metal sealing rings 121 and 122, gasket 2.

[0041] The nozzle 8 is provided with two inlet pipes 91, 92 and two outlet pipes 101 and 102 of Laval structure, and the angle between the central axes of the two outlet pipes 101 and 102 of the nozzle is between 20° and 75°. Between the outlet pipes 101 and 102 of the two laval structures of the nozzle 8, gaps 131 and 132 are set at the periphery of 10mm~100mm, and heating elements B111 and B112 are installed inside the gaps 131 and 132, and the outlet pipes of the two laval structures of the nozzle The ends of the gaps 131 and 132 between 101 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com