Numerical control submerged automatic arc welding device and numerical control submerged automatic arc welding method for saddle-shaped narrow bevel

A submerged arc automatic welding, saddle-shaped technology, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of low efficiency, manual adjustment, difficult to repair, etc., to achieve high quality and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

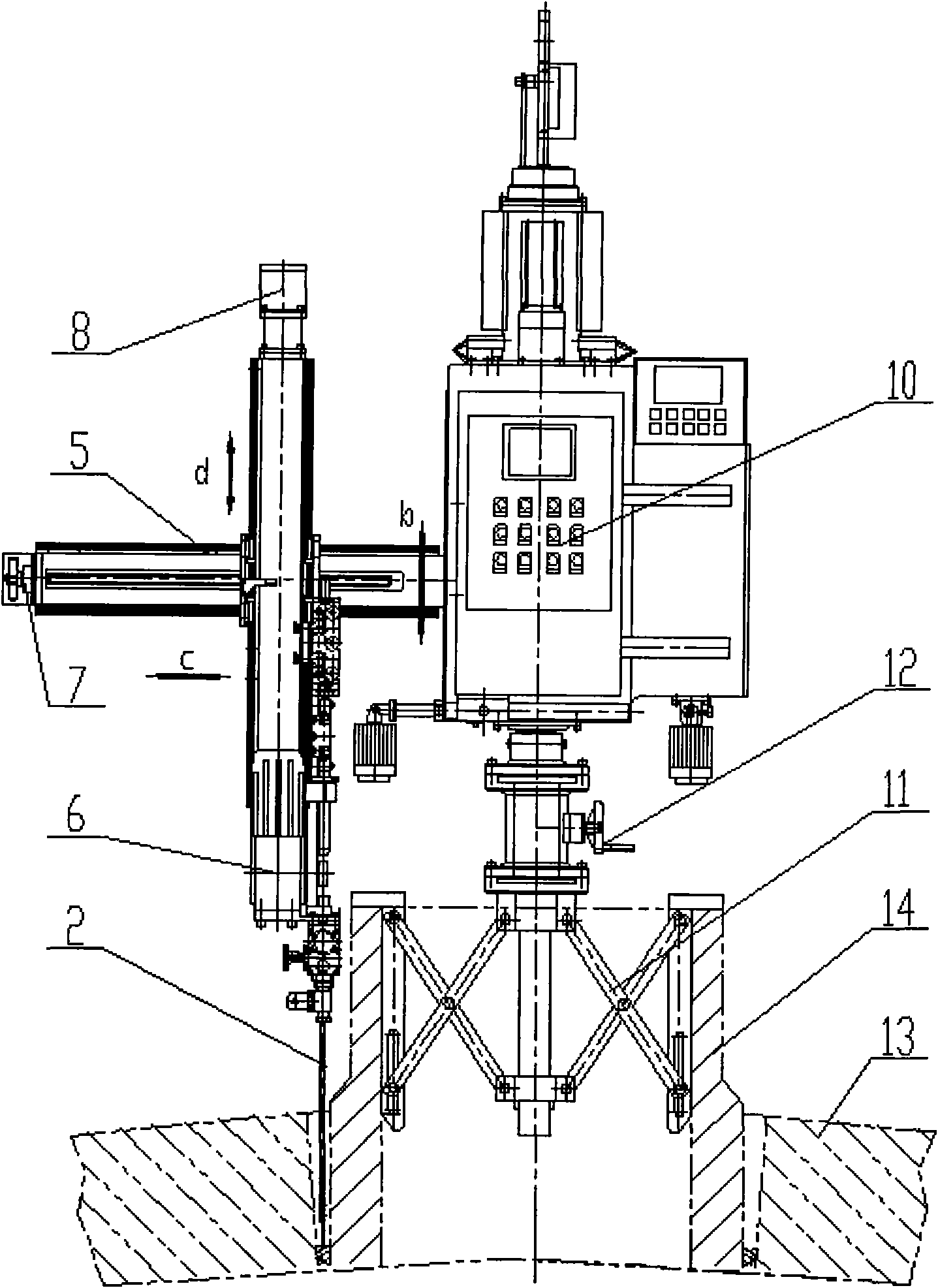

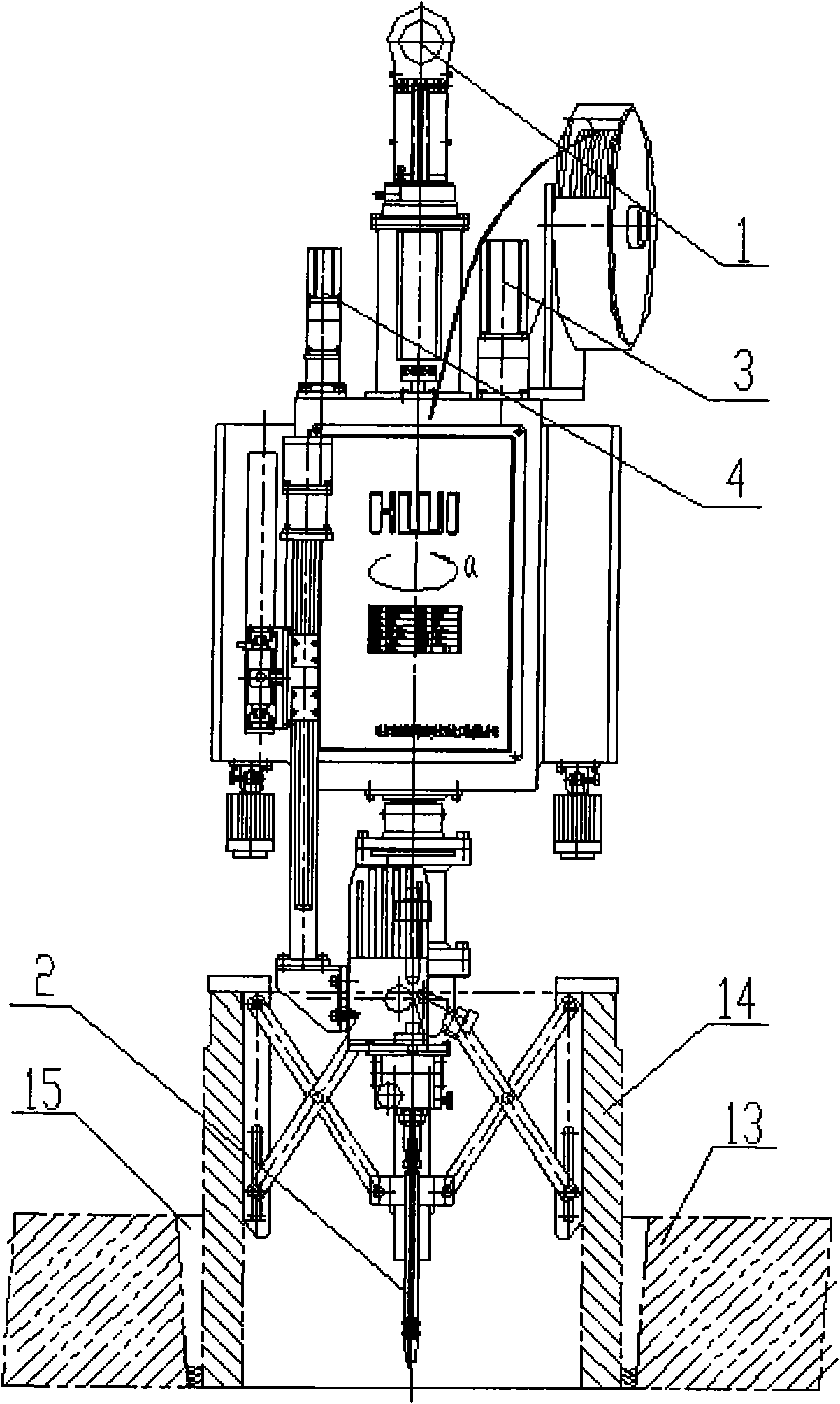

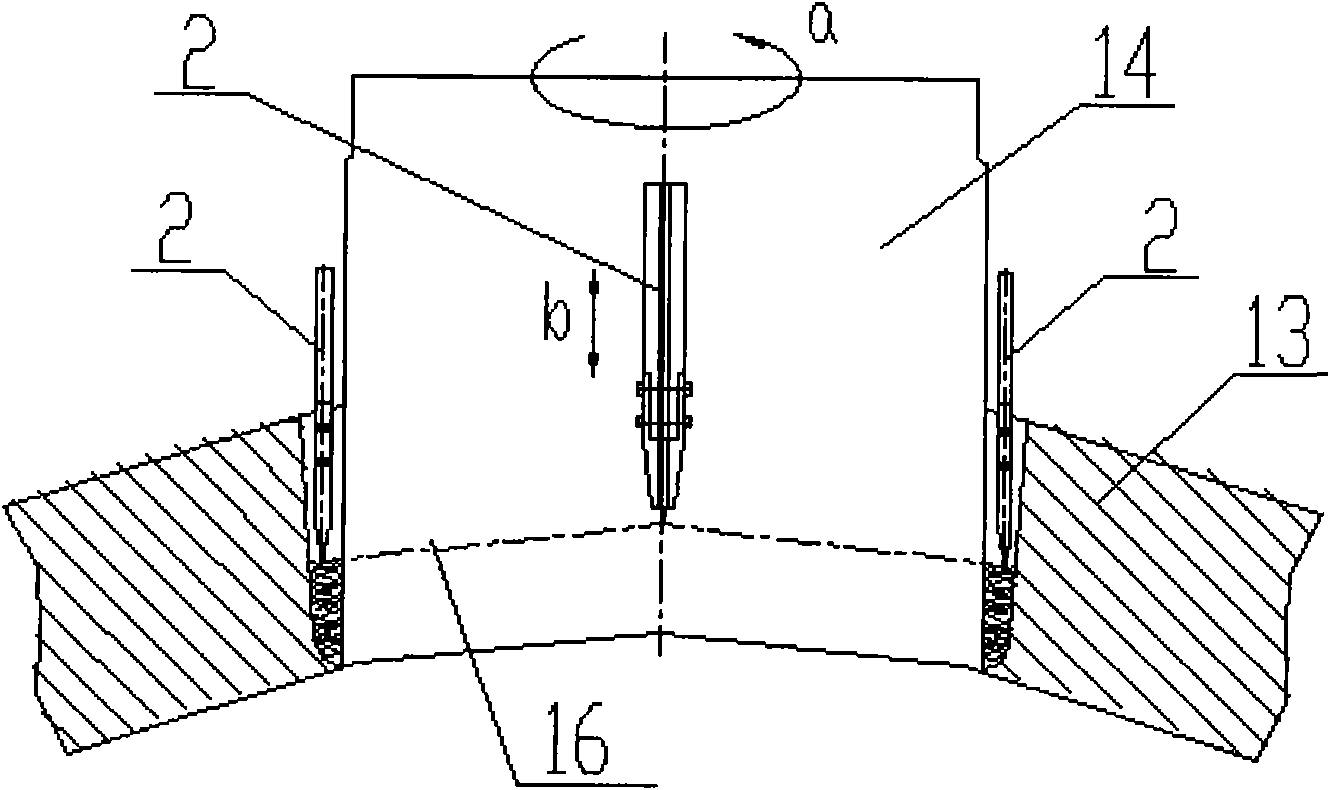

[0052] Lift the whole welding device to the top of the welded pipe 14 and the cylinder 13, the clamping and positioning device 11 falls into the inner hole of the connecting pipe 14, shake and turn the hand wheel 12, the clamping and positioning device 11 clamps the connecting pipe 14 and moves the welding torch 2 The center of rotation is positioned on the center of the socket 14 . Through the man-machine interface on the panel of the device control box 10, input the control parameters such as the diameter d of the welded connecting pipe 14 and the diameter D of the cylinder 13, as well as the welding thickness, number of welding layers, lap joint amount, number of welding passes per layer, etc., and then pass The welding control box inputs welding current, welding voltage and other process parameters to complete the parameter setting link.

[0053] Press the start button on the control panel 10 to start automatic welding. The welding torch head 2-1 is driven by the rotating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com