Stainless steel component for heating radiator and manufacturing method thereof

A kind of stainless steel and radiator technology, applied in household heating, heating methods, household heating and other directions, can solve the problems of weak welding, welding seam erosion, easy to produce leakage, etc., to achieve reliable fusion without leakage, neat welding seam Uniform and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described in detail below with reference to the drawings and embodiments.

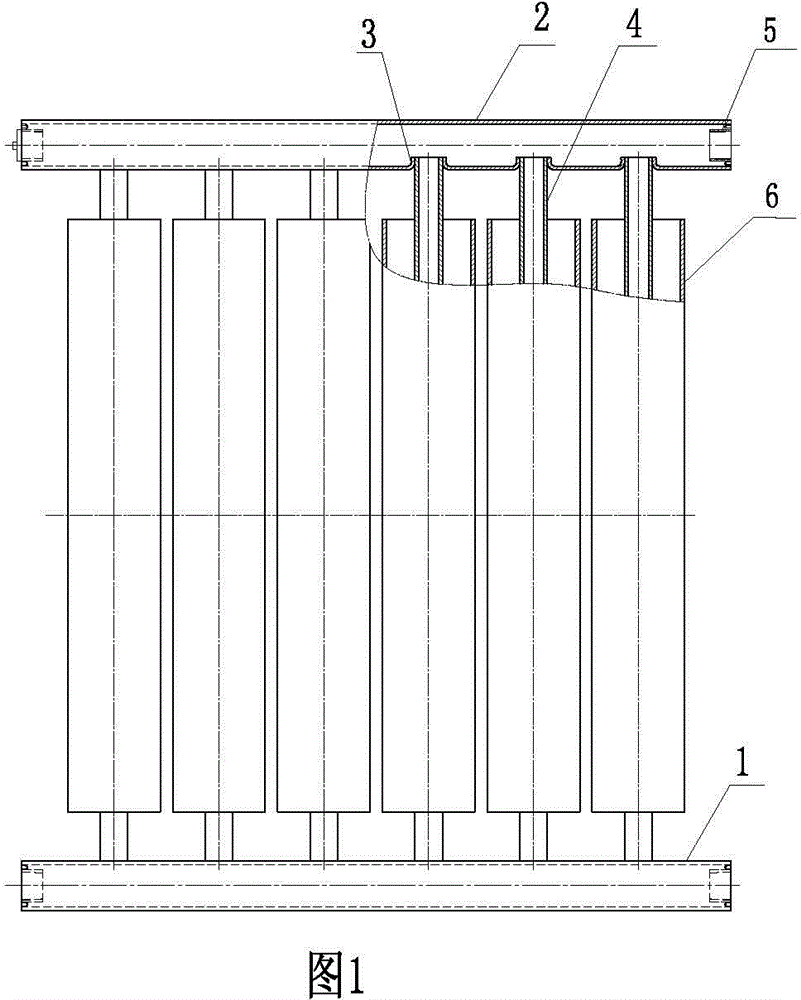

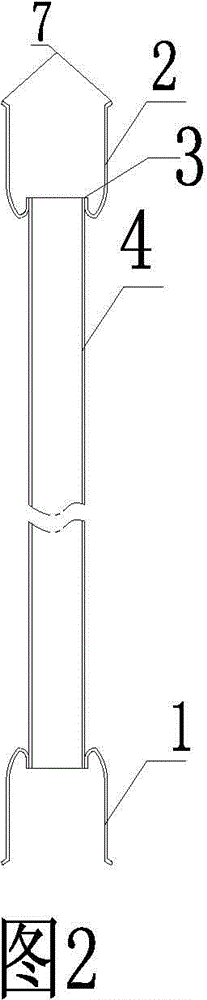

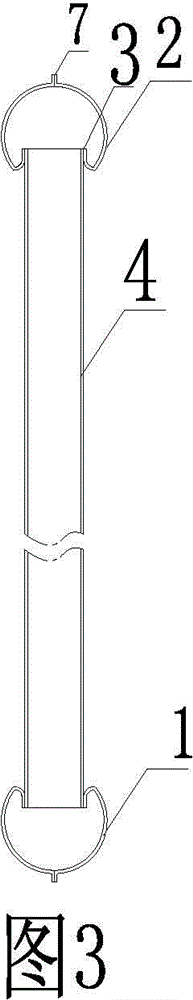

[0035] Such as figure 1 , figure 2 , image 3 As shown, a stainless steel component for a heating radiator includes two horizontally connected pipes 1 and 2 with the same structure up and down, and also includes a plurality of vertical risers 4 arranged in parallel. The two ends are respectively connected to the upper and lower horizontal communication tubes 1 and 2 through each other. The horizontal communication tubes are provided with a circular ring flange 3 protruding inward, and the ring flange 3 has an appropriate height. The through connection is that the vertical riser 4 is inserted into the inwardly convex annular flange 3 of the transverse connecting pipe, and the annular flange 3 of the transverse connecting pipe is closely attached to the wall of the vertical riser 4, and the vertical riser The end face of 4 is flush with the end face of the annul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com