Liquid cooled pipe and battery system

A pipeline and liquid cooling technology, which is applied in the field of liquid cooling pipelines and battery systems, can solve the problems of the uniformity of the surface temperature reduction affecting the heat dissipation efficiency of the power battery, the difficulty of using thermal conductive gel, and the high cost of the mold, so as to achieve flexible assembly and reduced cost. Small leakage risk, compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

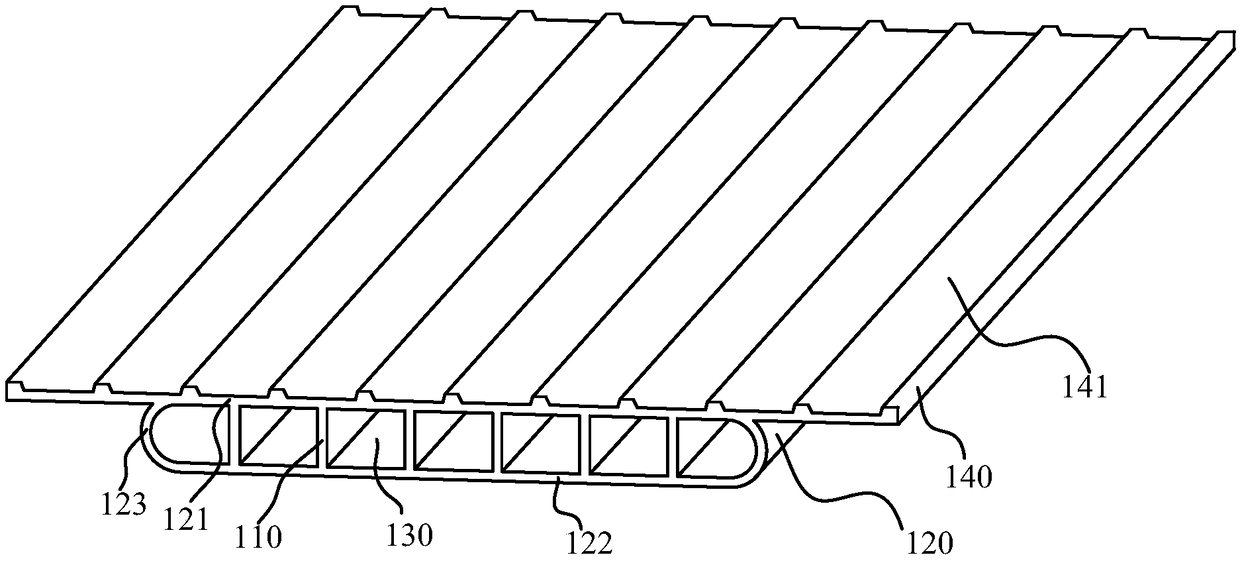

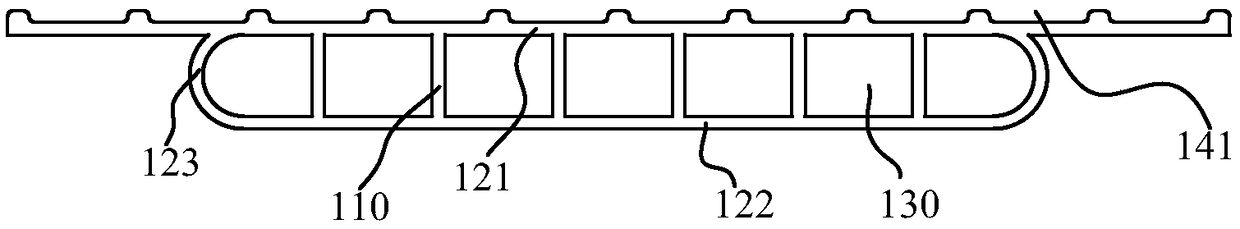

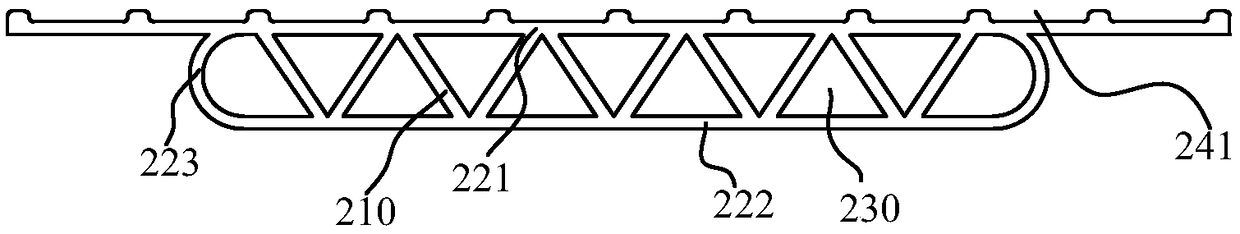

[0026] Hereinafter, the present invention will be described in more detail with reference to the accompanying drawings. In the various figures, identical elements are indicated with similar reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale. Also, some well-known parts may not be shown.

[0027] In the following, many specific details of the present invention are described, such as device structures, materials, dimensions, processing techniques and techniques, for a clearer understanding of the present invention. However, the invention may be practiced without these specific details, as will be understood by those skilled in the art.

[0028] figure 1 A schematic diagram showing the three-dimensional structure of the liquid cooling pipeline according to the first embodiment of the present invention, figure 2 A schematic cross-sectional view of the liquid cooling pipeline according to the first embodiment of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com