Dog-legged roof for railway boxcars

A railway boxcar and broken-line technology, applied in the field of railway freight cars, can solve problems such as disadvantage, increase the volume of the vehicle, reduce the self-weight of the vehicle, etc., and achieve the effects of high space utilization rate, enlargement of the cross-sectional area, and reduction of the self-weight of the vehicle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with embodiment the present invention is further described.

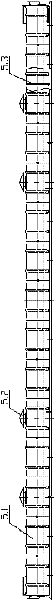

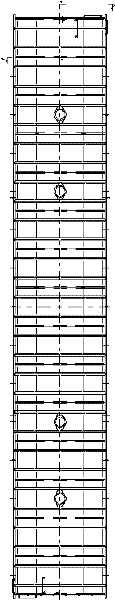

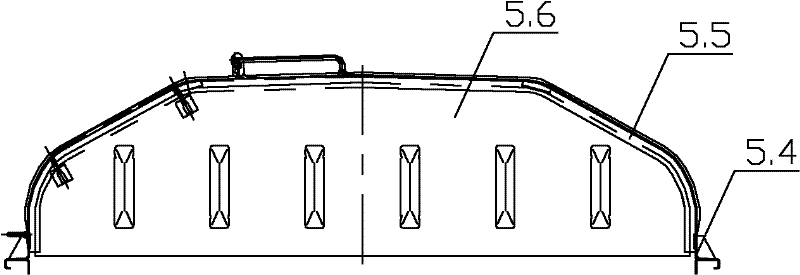

[0018] Such as Figure 1-Figure 4 As shown, the zigzag roof of the railway box car includes roof plate 5.1, ventilator 5.2, roof curved beam 5.3, roof side beam 5.4, car top curved beam 5.5 and car top plate 5.6; roof plate 5.1 is embossed Rib bending structure, the roof bending beam 5.3 is a flat steel bending structure, the roof side beam 5.4 and the top bending beam 5.5 are cold-formed angle steel; the two sides of the roof panel 5.1 in the middle overlap with the roof bending beam 5.3 , the roof panel 5.1 at the end is overlapped with the roof curved beam 5.3 and the top curved beam 5.5 respectively; both ends of the entire roof panel 5.1 are overlapped with the roof side beam 5.4; the top panel 5.6 is a steel plate embossed rib structure , the upper part of the top plate 5.6 is lapped with the curved beam 5.5 at the top of the car.

[0019] The roof panel 5.1 is a steel plate press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com