Suspension type train track beam, manufacturing method thereof and technical partition plates for track beam

A manufacturing method and technology of track beams, which are applied to the technical partitions of track beams, suspended train track beams and their manufacturing fields, can solve the problems of ensuring the structural size and line shape of track beams, and the inability to use partitions, etc., to achieve fast Welding, the effect of high dimensional accuracy of cross-sectional structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings.

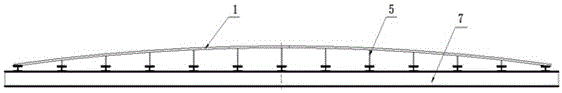

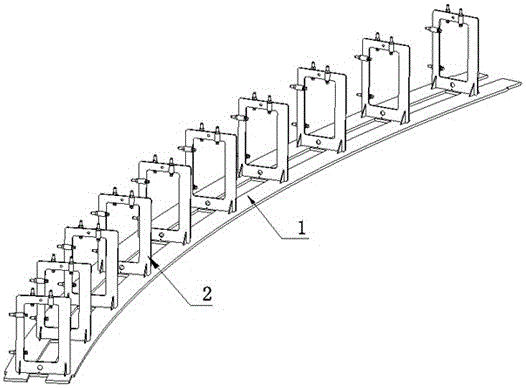

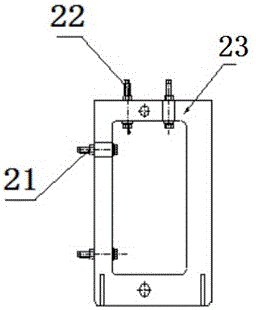

[0032] Such as Figure 1-4 As shown, the present invention provides a kind of suspended train track beam, comprises upper cover plate 4, lower cover plate 1, web 3 and rib plate 9, as figure 1 As shown, the bottom of the lower cover 1 is provided with a limit stop 5 for adjusting the camber of the lower cover 1, and the camber curve of the track beam is guaranteed by the height of the limit stop; as figure 2 As shown, a number of detachable process partitions 2 are installed along the length direction of the lower cover plate 1, including a plate body 23. In order to reduce its own weight, the plate body 23 is a back-shaped structure. Such as image 3 As shown, one side of the process partition 2 is provided with a first adjustment screw 21 for adjusting the web 3, and the top of the process partition 2 is provided with a second adjustment screw 22 for adjusting t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com