LED lamp string, and manufacturing method thereof and LED device used in LED lamp string

A technology of LED devices and LED light strings, which is applied to semiconductor devices of light-emitting elements, electric solid-state devices, semiconductor devices, etc., can solve problems such as increased production costs, troublesome operation, and weak welding, so as to improve the yield rate and increase production. efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

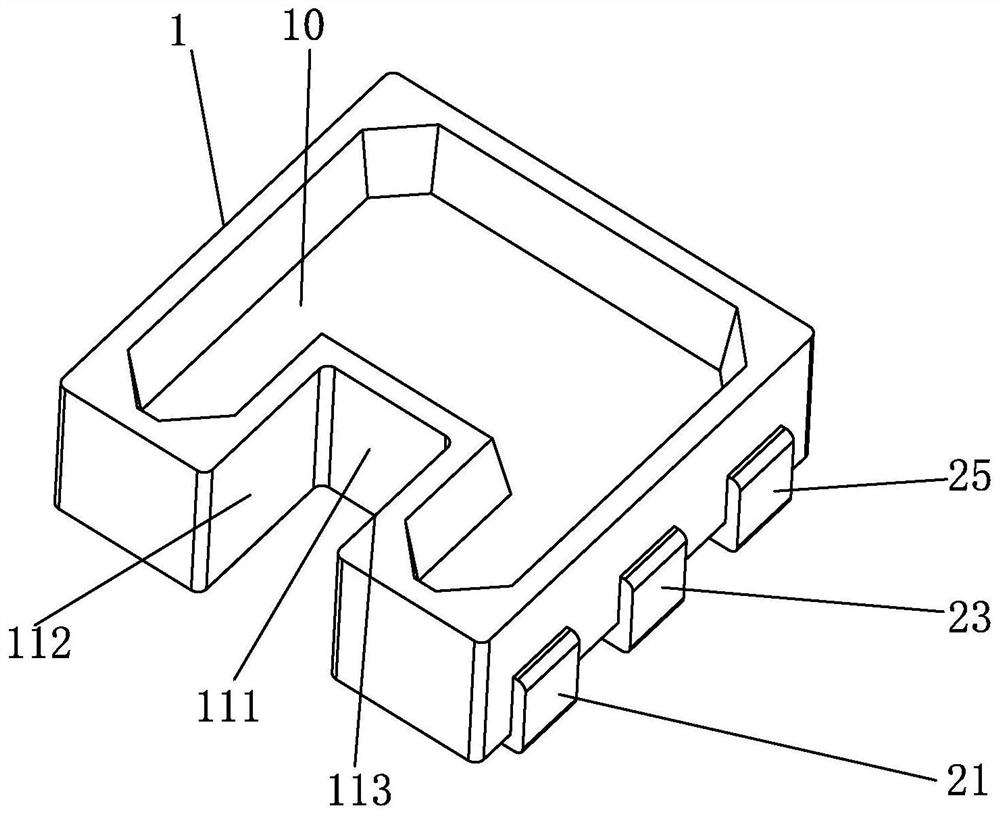

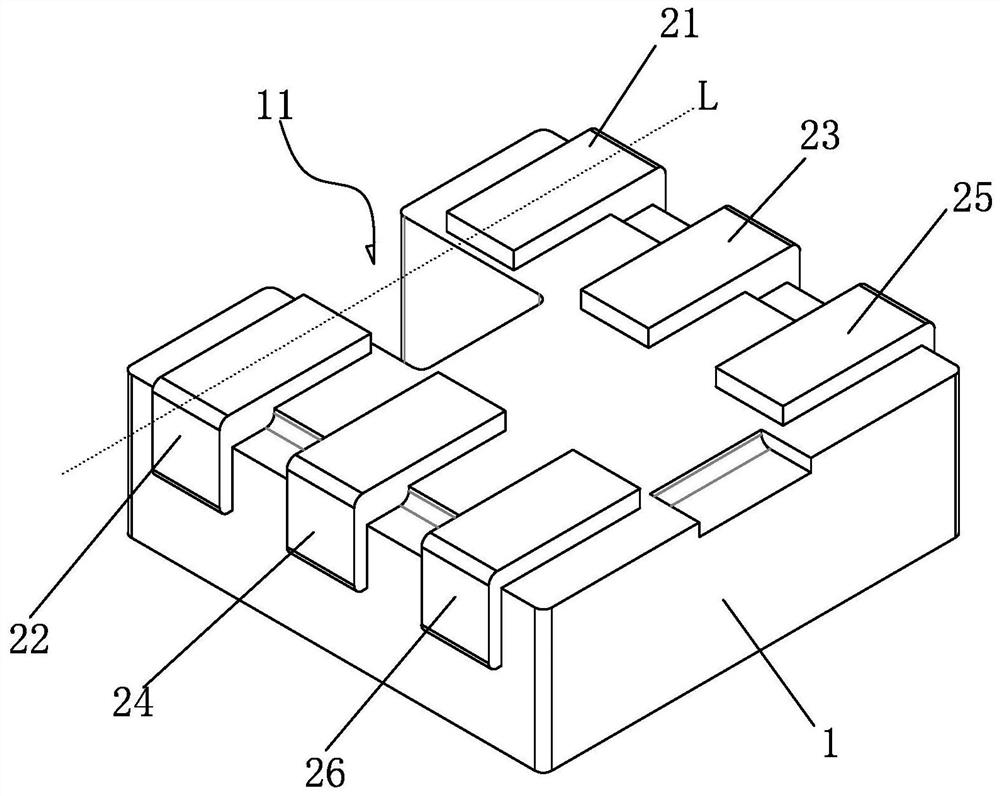

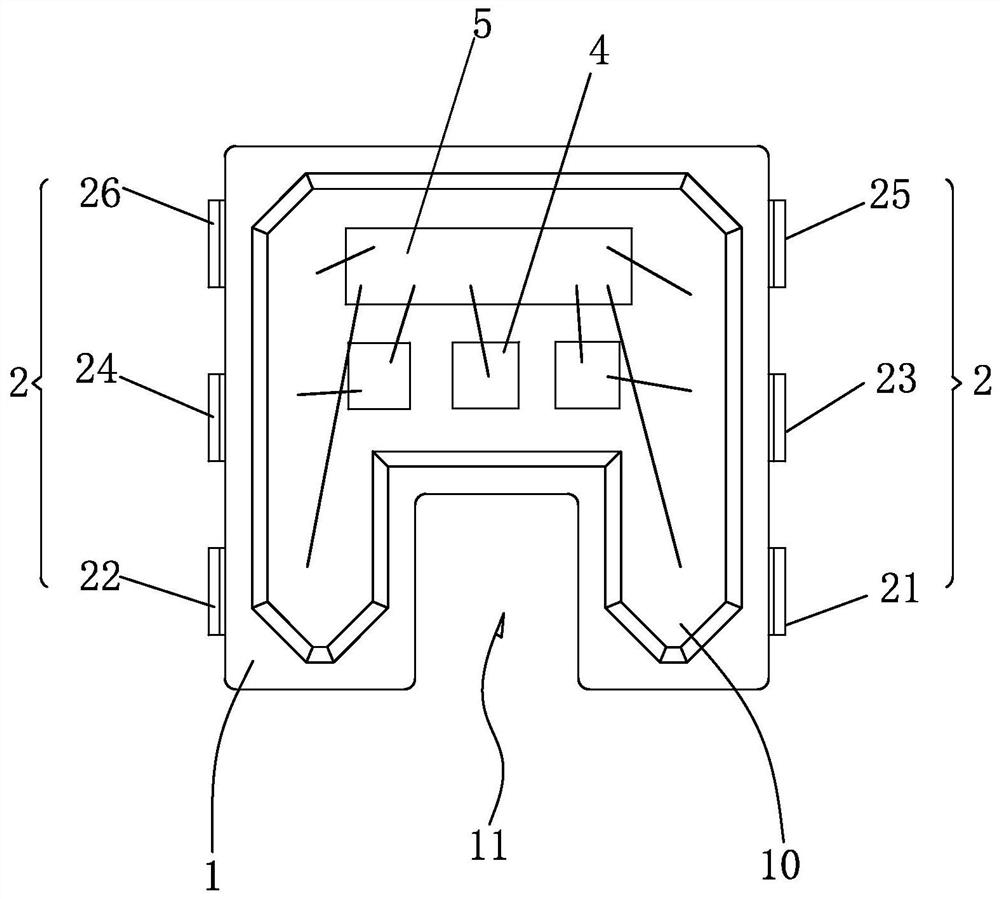

[0035] For the convenience of description, the LED device in the present invention will be described first. See Figure 1 to Figure 3 As shown, this is the first embodiment of the LED device of the present invention, which includes: an insulating body 1 , a conductive terminal 2 fixed to the insulating body 1 , and an LED chip 4 and a control unit 5 for emitting light.

[0036] The insulating body 1 is made of insulating materials such as plastic or ceramics, and an accommodating cavity 10 is formed in a downward depression on the surface of the insulating body 1 . The accommodating cavity is used for arranging components such as the LED chip 4 and the control chip as the control unit 5 , and finally the entire accommodating cavity 10 is encapsulated by materials such as plastic resin. An inwardly recessed notch 11 is formed on the insulating body 1 . The notch 11 avoids the position of the accommodating cavity 10 and penetrates along the surface and the bottom surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com