Natural gas cylinder liner for drawing process forming

A technology for natural gas and gas cylinders, which is applied in the field of natural gas cylinder liners formed by stretching technology, and can solve the problems affecting the vacuum degree of gas cylinder liners, leakage rate, leakage rate and static evaporation rate technical indicators, three welds Difficult to guarantee quality, difficult to control welding quality and other issues, to achieve the effect of improving welding assembly efficiency and precision, uniform and reliable thickness, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

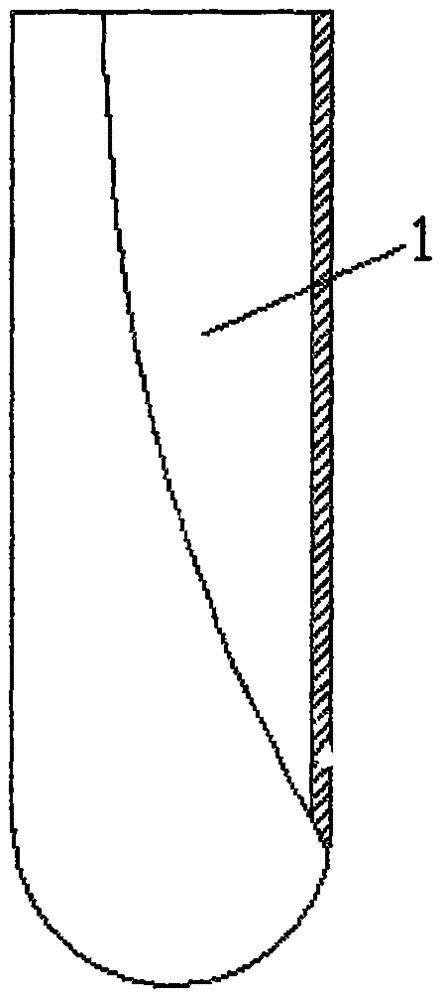

[0032] Such as figure 1 As shown, this figure is a schematic diagram of the welding structure of the inner tank in the prior art. The cylinder body is welded, and the two ends are welded separately by the end cap.

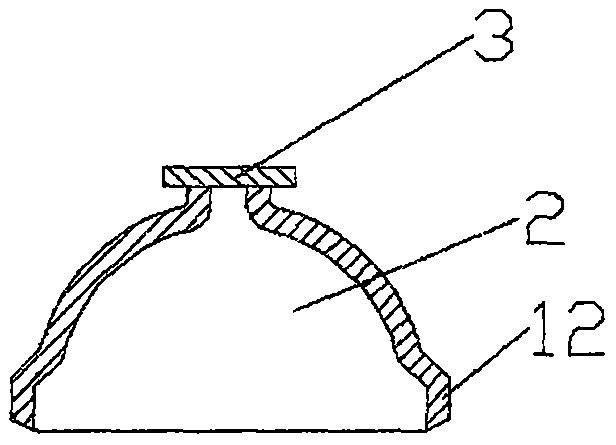

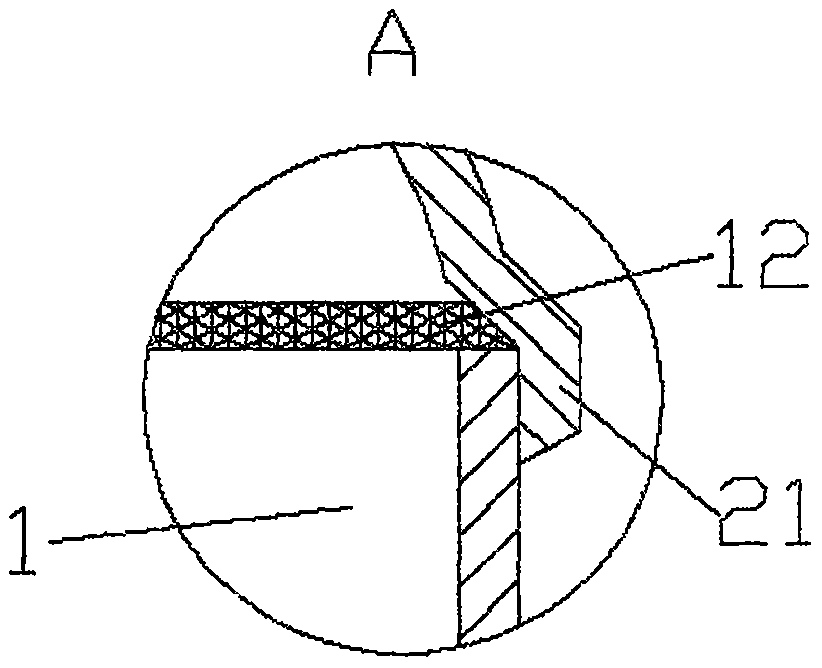

[0033] In this specific embodiment, in combination with the attached figure 2 , 3 , 4, and 5, the liner of this natural gas cylinder formed by a stretching process includes a cylinder (1) and a head (2), and it is characterized in that the cylinder (1) and the seal The head (2) is welded to form a closed annular inner cavity, wherein the cylinder body (1) and the head (2) are all of an integrated structure, and due to the integrated structure of the cylinder body (1), reducing The amount of welding is reduced, the processing cost is reduced, and problems such as welding deformation and missing welding of the cylinder body (1) caused by large-area weldin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com