Steel rib double-T-shaped column and manufacturing method thereof

A manufacturing method and technology of T-shaped pillars, which are applied in the field of electric wires, can solve problems such as potential safety hazards and poor supporting capacity, and achieve the effects of improving safety, improving supporting force, and increasing connectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

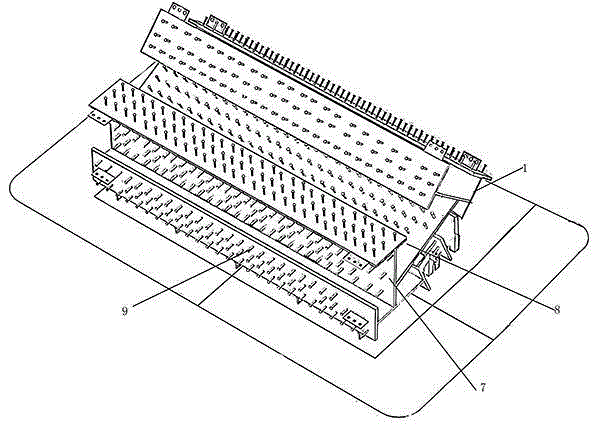

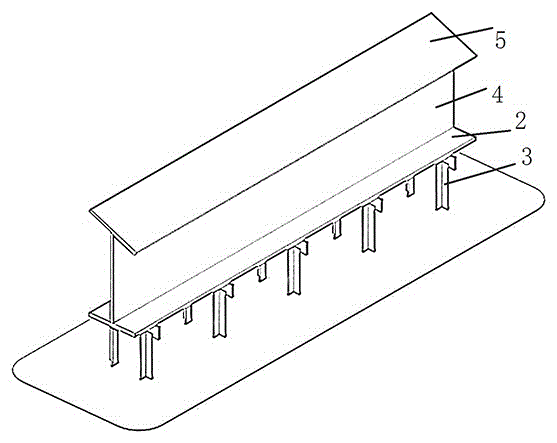

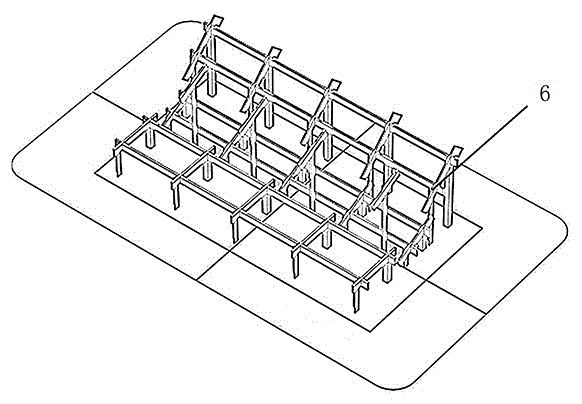

[0035] like figure 1 , figure 2 and image 3 A steel double T-shaped column shown includes: a bottom plate 2, a construction frame 3, a support plate 4, an upper cover plate 5, a support tire frame 6, a T-shaped unit 7, a connecting plate 8 and a peg 9. The bottom plate 2 is set on the construction frame 3, the support plate 4 is set on the bottom plate 2, the upper cover plate 5 is set on the top of the support plate 4 to form an H-shaped unit 1, and the support tire frame 6 is fixed on the specified In the construction site, the H-type unit 1 is fixed on the support frame 6, the T-type unit 7 is vertically arranged on the H-type unit 1, and the H-type unit 1 is divided into two T-type units 7, and the The connecting plate 8 is arranged between two T-shaped units 7 , and the pegs 9 are arranged on each board surface of each T-shaped unit 7 .

[0036] The supporting frame in this embodiment is composed of three groups of frames, which are respectively the first frame, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com