Large-current planar transformer assembling equipment and assembling method

A technology for planar transformers and assembly equipment, which is applied in the manufacture of inductors/transformers/magnets, circuits, and electrical components. Improve assembly yield and consistency, improve regularity and efficiency, and reduce assembly difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

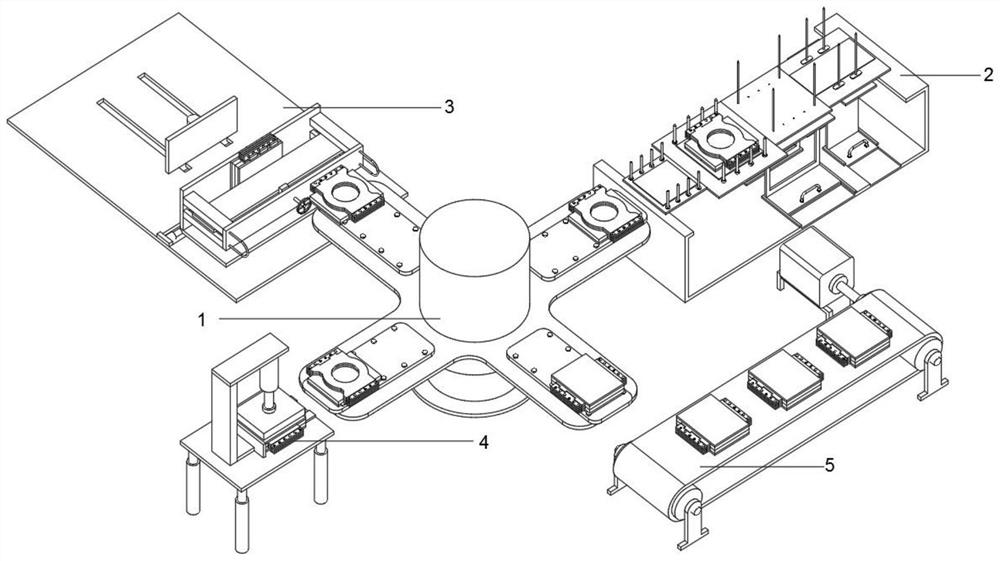

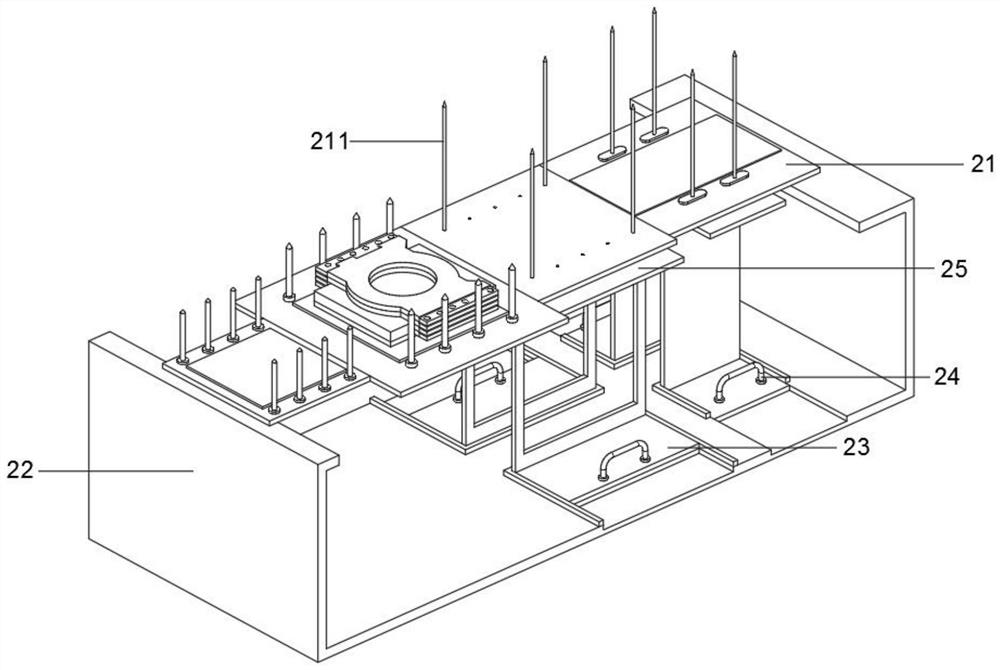

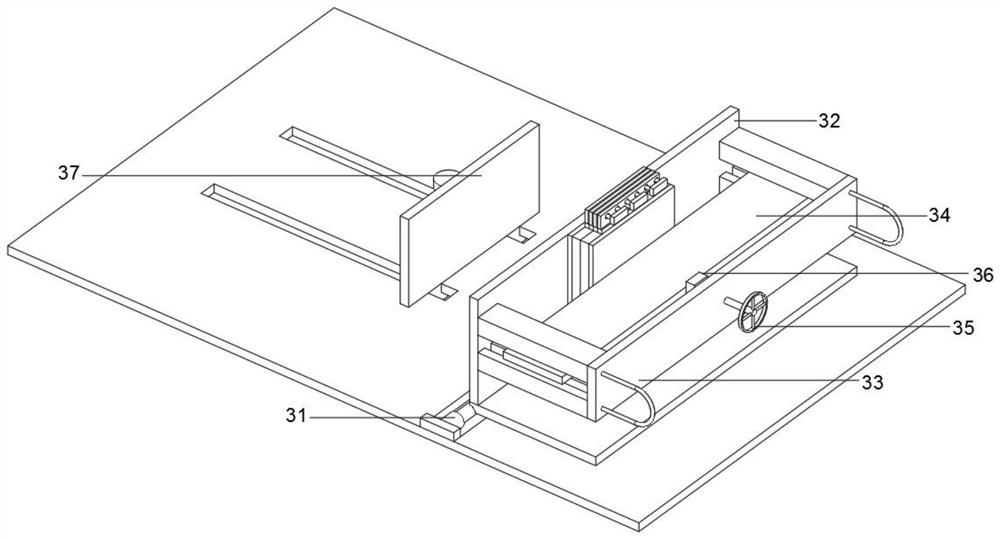

[0033] Such as Figure 1-6 As shown, a high-current planar transformer assembly equipment includes a four-station turntable 1, a coil fixture 2, a coil pin fixture 3 and an overall alignment fixture 4, and one side of the four-station turntable 1 is provided with a conveyor belt for outputting finished transformers 5. The coil fixture 2, the coil pin fixture 3, the overall alignment fixture 4 and the conveyor belt 5 are arranged equidistantly clockwise with the four-station turntable 1 as the center of the circle, and the coil pin fixture 3 is equipped with multiple limit clamps The structure is convenient for coil pin access, and the four stations of the four-station turntable 1 correspond to the assembly steps of the high-current planar transformer, which significantly improves the regularity and efficiency of the assembly, while the assembly of the coil pins At the same time, the clamping structure in the coil pin fixture 3 provides a tight pressure limit on the top and bot...

Embodiment 2

[0043] Such as Figure 1-6 As shown, a high-current planar transformer assembly equipment includes a four-station turntable 1, a coil fixture 2, a coil pin fixture 3 and an overall alignment fixture 4, and one side of the four-station turntable 1 is provided with a conveyor belt for outputting finished transformers 5. The coil fixture 2, the coil pin fixture 3, the overall alignment fixture 4 and the conveyor belt 5 are arranged equidistantly clockwise with the four-station turntable 1 as the center of the circle, and the coil pin fixture 3 is equipped with multiple limit clamps The structure is convenient for coil pin access, and the four stations of the four-station turntable 1 correspond to the assembly steps of the high-current planar transformer, which significantly improves the regularity and efficiency of the assembly, while the assembly of the coil pins At the same time, the clamping structure in the coil pin fixture 3 provides a tight pressure limit on the top and bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com